No water to newly installed Moen Posi-Temp shower head. This has never happened before. So I'm thinking bad cartridge? I run down the hill and pick up a 1222 cartridge for the Posi-Temp and no luck with it. Absolutly nothing comes out of the shower head. The next day I swing by my supplier and pick up a new valve body. I ask the plumber next to me if he ever encountered anything like that. His reply,

"Yes, that small hole can fill with solder."

What? Seriously?

"Yep. Done it."

So I pick up the new Moen 62320 valve and head up to yesterdays job. I shut down the water again, cut the valve out, remove the cartridge and try blowing air though the top port. Nothing. Absolutely nothing.

This time I solder most of the valve up on the horizontal, like I have done most of the time. I then put it up in the hole and solder very carefully the top joint.

It works perfectly now. So yes, the mystery of missing water solved. Don't use so much solder on a vertical joint at the top of the Moen Posi-Temp valve body.

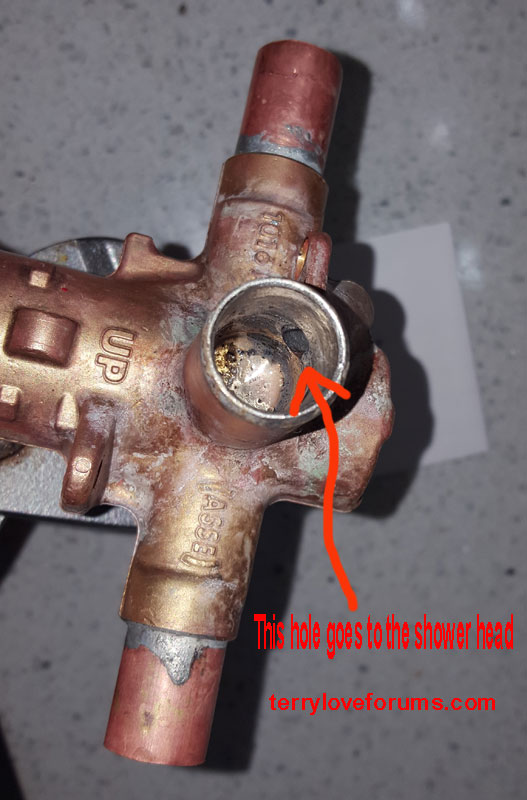

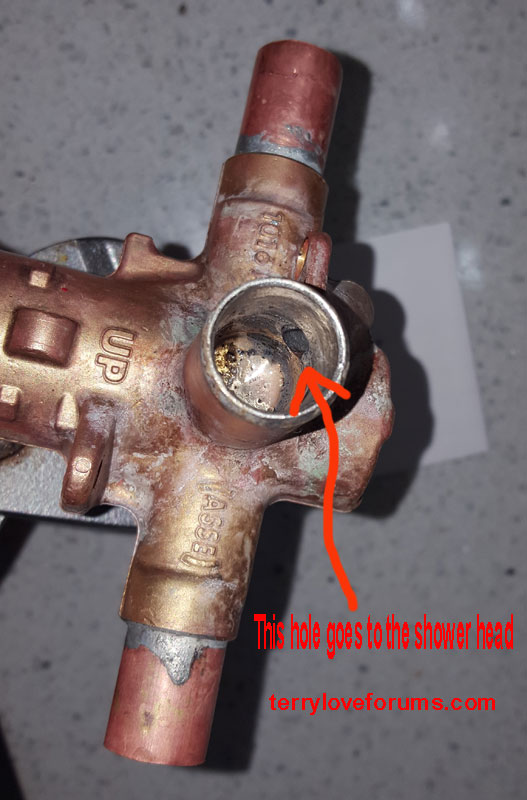

That little hole that looks dark is the hole that supplies the shower head. Fill it with solder and nothing will come out.

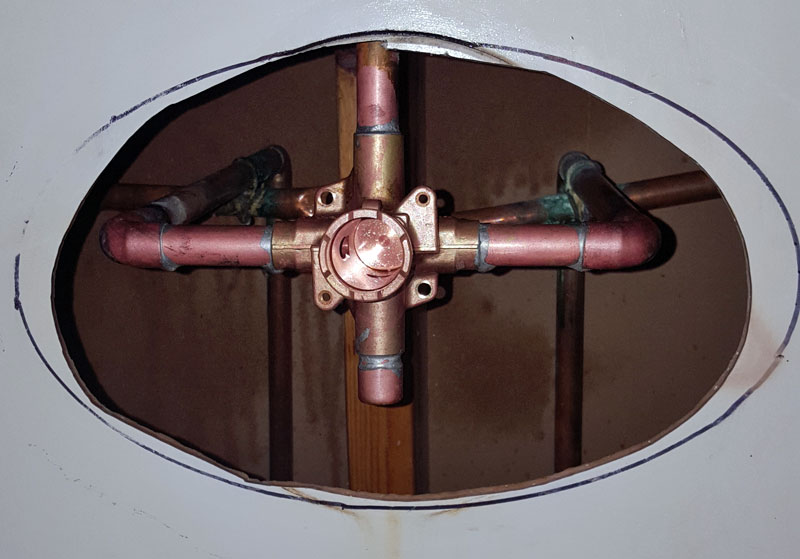

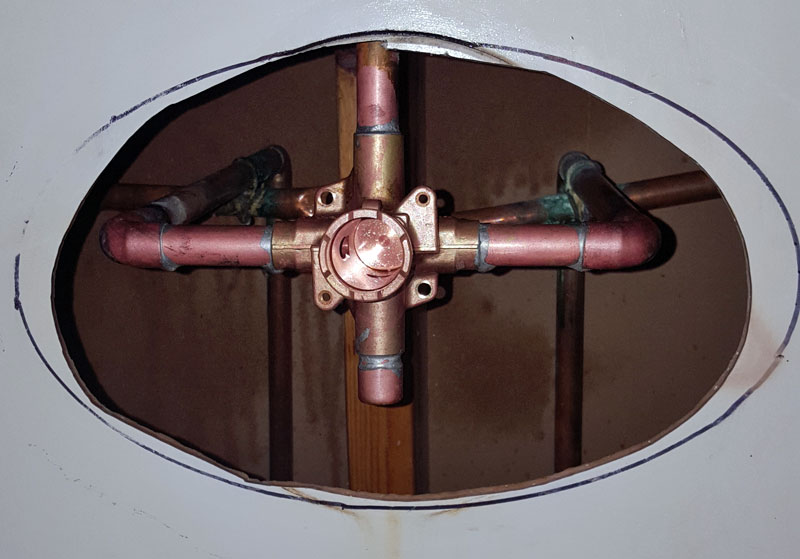

The new Posi-Temp

And trimed out.

Here is a comment by John J Okeef,

"I'll admit i took the lazy way out i put the torch 2 the body and blew air thru the shower arm. It was me and a supply line."

John, I wish I had tried something like that now.

"Next time just take cartridge out and heat up body, you may get lucky, I did more than once"

"they should make the port a little bigger, it's ridiculous how small it is"

Christopher M.

"Yes, that small hole can fill with solder."

What? Seriously?

"Yep. Done it."

So I pick up the new Moen 62320 valve and head up to yesterdays job. I shut down the water again, cut the valve out, remove the cartridge and try blowing air though the top port. Nothing. Absolutely nothing.

This time I solder most of the valve up on the horizontal, like I have done most of the time. I then put it up in the hole and solder very carefully the top joint.

It works perfectly now. So yes, the mystery of missing water solved. Don't use so much solder on a vertical joint at the top of the Moen Posi-Temp valve body.

That little hole that looks dark is the hole that supplies the shower head. Fill it with solder and nothing will come out.

The new Posi-Temp

And trimed out.

Here is a comment by John J Okeef,

"I'll admit i took the lazy way out i put the torch 2 the body and blew air thru the shower arm. It was me and a supply line."

John, I wish I had tried something like that now.

"Next time just take cartridge out and heat up body, you may get lucky, I did more than once"

"they should make the port a little bigger, it's ridiculous how small it is"

Christopher M.

Last edited: