Iitalnsd

New Member

Hello,

I need to substitute the cartridge of my old Moen pull-out shower handle that has become so hard to push back in that in the last attempt I broke the faceplate. The problem is that I live in a condo and I can't switch off the water to my apartment without affecting the whole column (which requires a week notice).

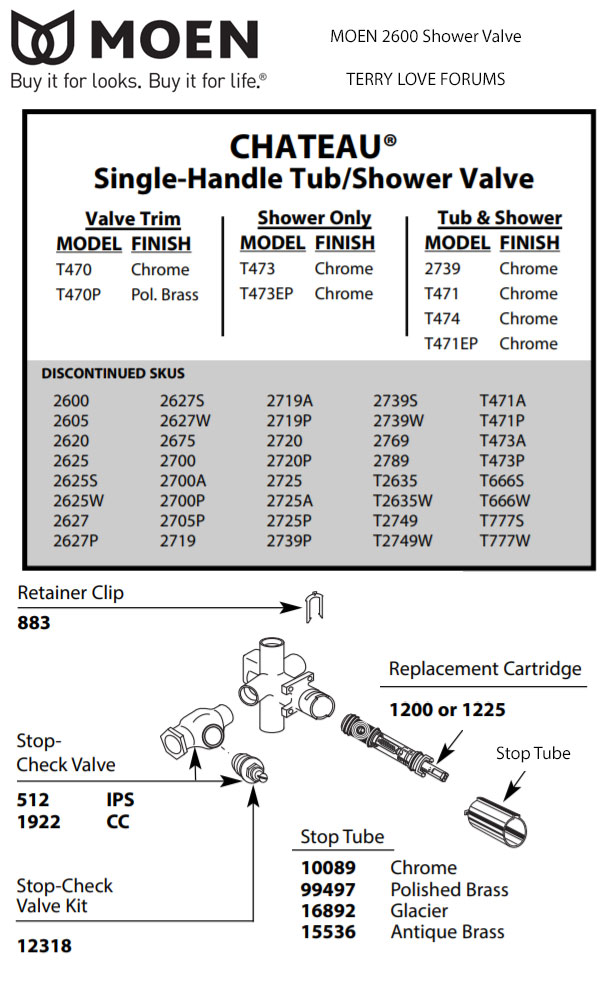

For this reason, I was thrilled when, taking off the broken faceplate, I discovered that it hid the two screwdriver-operated shut-off valves shown in the picture below (I think they are properly called stop valves). After some Internet search, I learnt that there are possibly two types of those stop valves used by Moen: one type only moves by a quarter turn (open when the screw mark is horizontal, close when vertical) and an older type that gets closed by turning the screw clockwise for as long as its travel allows. Considering the position of the screws in the pic, I assume I have the older type.

What I regarded as a lucky break, however turned quickly into a source of huge frustration as I have been unable to move any of the screws by a single degree, either by applying the full stall torque of my drill and my impact driver, or even letting the latter run for a short series of impact hits (I was a bit reluctant of using the full force of the impact driver as I feared it could damage the valve, but I was hoping a few hits could produce enough vibrations to unstuck the valve). Not even using a heat gun produced any result.

Is there anything else I should try? Maybe let the impact driver do its job without taming it? Was the heating gun counterproductive by causing further expansion and I should try using some freezing spray?

I have seen that there are impact screwdriver that are actuated by hitting the top with a hammer. Hovever I can't see them being useful in this case, as the screw is not sitting on a stiff structure and it would move by effect of the hammer blow without producing the necessary reaction force.

Any suggestion would be highly appreciated as I feel I am as stuck as the two valves.

Thanks

I need to substitute the cartridge of my old Moen pull-out shower handle that has become so hard to push back in that in the last attempt I broke the faceplate. The problem is that I live in a condo and I can't switch off the water to my apartment without affecting the whole column (which requires a week notice).

For this reason, I was thrilled when, taking off the broken faceplate, I discovered that it hid the two screwdriver-operated shut-off valves shown in the picture below (I think they are properly called stop valves). After some Internet search, I learnt that there are possibly two types of those stop valves used by Moen: one type only moves by a quarter turn (open when the screw mark is horizontal, close when vertical) and an older type that gets closed by turning the screw clockwise for as long as its travel allows. Considering the position of the screws in the pic, I assume I have the older type.

What I regarded as a lucky break, however turned quickly into a source of huge frustration as I have been unable to move any of the screws by a single degree, either by applying the full stall torque of my drill and my impact driver, or even letting the latter run for a short series of impact hits (I was a bit reluctant of using the full force of the impact driver as I feared it could damage the valve, but I was hoping a few hits could produce enough vibrations to unstuck the valve). Not even using a heat gun produced any result.

Is there anything else I should try? Maybe let the impact driver do its job without taming it? Was the heating gun counterproductive by causing further expansion and I should try using some freezing spray?

I have seen that there are impact screwdriver that are actuated by hitting the top with a hammer. Hovever I can't see them being useful in this case, as the screw is not sitting on a stiff structure and it would move by effect of the hammer blow without producing the necessary reaction force.

Any suggestion would be highly appreciated as I feel I am as stuck as the two valves.

Thanks