I'm looking at the cap to my well trying to figure out how to remove the cap. I need to determine pump depth, and static water level. It looks like a bolt has been modified to allow water line to extend from the top of the cap.

1. is there a way to remove the modified bolt at the pvc pipe, or should i loosen up the other 3 and see if I can get it out with just 3 loose bolts?

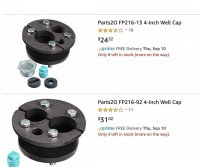

I will probably be replacing the cap and re-working the plumbing and electrical.

Thanks the the forum set-up for not having weird requirements to have "X" amount of posts to upload photos, most helpful and practical.

1. is there a way to remove the modified bolt at the pvc pipe, or should i loosen up the other 3 and see if I can get it out with just 3 loose bolts?

I will probably be replacing the cap and re-working the plumbing and electrical.

Thanks the the forum set-up for not having weird requirements to have "X" amount of posts to upload photos, most helpful and practical.

Last edited: