theunit

New Member

Hi all - Thanks for your insights previously and taking a look at this post. I have read several other, similar posts that deal with this issue, but thought it would be beneficial to share my particular situation with a photo. Appreciate any thoughts you have or your experience if you have a similar setup.

The scenario:

The questions:

Thank you

The scenario:

- .75" hot and cold supply to within a few feet of the shower I am building, which is on the second story of the home

- .5" PEX H & C coming off the .75" supply lines running to the shower valve

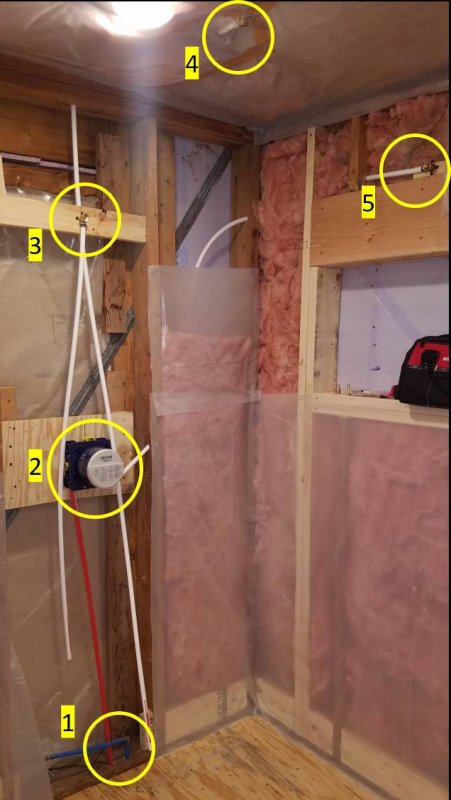

- .5" PEX teeing off to the bathroom toilet (#1 in the image)

- Shower valve is a .5" Grohe Smartcontrol, for reference

- Three individual .5" PEX lines planned for three shower fixtures - two standard shower heads and one rain shower head (#'s 3, 5 and 4 in the image, respectively)

- All shower fixtures are rated at 2.5 GPM

- Water flow and pressure throughout the home seems strong at every other outlet

- Main water supply is located two floors directly below the shower area

- Two 50 gallon water heaters supply hot water

- As you can see in the image, I still have significant work to do, not the least of which is strapping and supporting the PEX, etc.

The questions:

- Will this system, as is, provide a decent pressure/flow to the three shower fixtures? Either, one, two or all three of them on/any combination thereof? I am concerned about the ID of the transitions in the PEX, at the valves and transitions to fixtures.

- Excluding tearing apart the floor to plumb .75" supply to the .5" valve, would I benefit from using .75" PEX from the valve to the three shower fixtures? i.e. after getting to the valve, would this allow more water to 'build up' behind the shower fixtures for better pressure/flow?

- What else am I not thinking about to ensure a good experience down the road?

Thank you