traut27

New Member

My laundry room currently has a washer draining into utility sink. I am updating the laundry room and would prefer to have laundry drain to a stand pipe and not the sink. The sink connects to a 1.5" though and not 2" drain pipe. It has a 90 elbow and goes straight down into the concrete slab.

1. Is my utility sink currently not vented? I don't see a vent pipe anywhere and don't see how one could hook into the drain pipe.

2. Was considering attempting a 1.5" drain pipe with a AAV but hesitant since I'm not even sure how the sink is vented currently. Is this something that could potentially work?(I know 2" is needed for code)

3. Is the only solution to drill up the concrete to see where the pipe goes and replace the 1.5" with 2"?

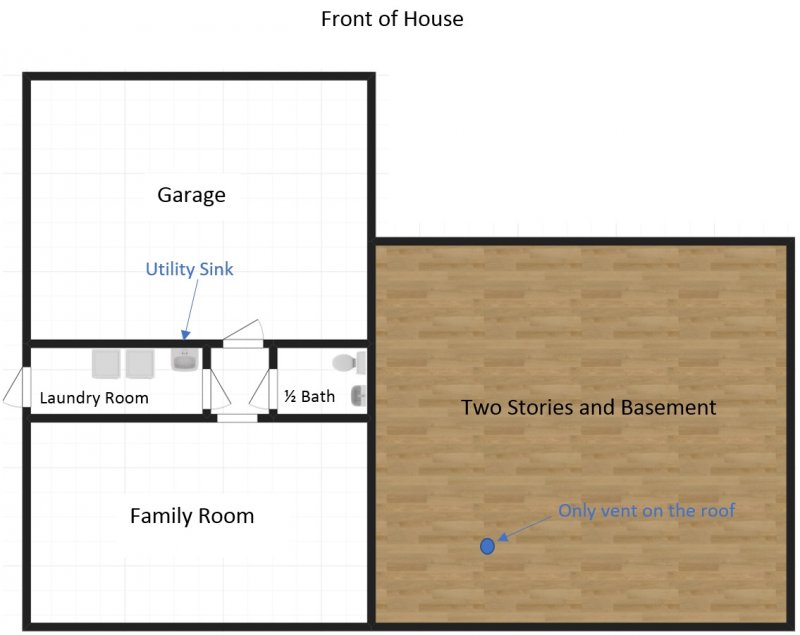

I think the main drain pipe is under/in the concrete slab portion of my house and runs out toward the front of the house. In the picture the white rooms are the ones on top of the concrete slap :

1. Is my utility sink currently not vented? I don't see a vent pipe anywhere and don't see how one could hook into the drain pipe.

2. Was considering attempting a 1.5" drain pipe with a AAV but hesitant since I'm not even sure how the sink is vented currently. Is this something that could potentially work?(I know 2" is needed for code)

3. Is the only solution to drill up the concrete to see where the pipe goes and replace the 1.5" with 2"?

I think the main drain pipe is under/in the concrete slab portion of my house and runs out toward the front of the house. In the picture the white rooms are the ones on top of the concrete slap :