TL;DR: The only direct questions in this post are at the bottom, and are not reliant on the info in this post. However, I'm hoping folks will corroborate or pull apart what else I've written.

To recap, I've got a short-cycling problem. In this specific situation, merely installing a CSV has been ruled out. Since then, I've been (slowly) checking out matters related to the VFD, larger pressure tank, and pump change plus CSV options.

1) The VFD option

Since the last post, I started a new thread about VFDs (

VFD installers: Mix & match brands? Use 1-phase motor? Test well pumping level?), and presently I'm not thrilled about that route.

2) Relevant power

I think the nominal HP may be the power the motor needs to deliver to the wet end of the pump when the pump is pumping at its nominal gpm. So it may be more a spec of the wet end than the motor end.

Not sure, and I don't have references along those lines.

I read more of the Grundfos pump handbook (a rather nice document), and it backs you up:

"Normally, pump curves in data booklets only cover the pump part. Therefore, the power consumption, the P_2-value, which is listed in the data booklets as well, only covers the power going into the pump – see figure 1.1.4. The same goes for the efficiency value, which only covers the pump part (η = η_P)." (page 9)

Motors on the other hand seem to be referred to by their output power, which all makes it seem rather straightforward to pair a motor & pump. As a result though, non-specific "power" then becomes a source of trouble when one is concerned with the inputs & outputs (electrical power & hydraulic power respectively (or what you pay & what you get)) of the motor + pump assembly.

The Goulds/Xylem technical support number was perpetually busy, and they did not respond to my voicemail or form request. Fortunately, their documents do list the electrical specs of their motors, giving the following power requirements for the motor I think I have (CentriPro M10412, generation 2, post November 2015, CSIR):

Full load: 1.175kW (~1.6HP)

Service factor: 1.590kW (~2.1HP)

Thus, the normal maximum running electrical input power of my "1HP" submersible pump is just over 2HP (note the service factor is only 1.4x).

3) Geothermal profile

I finished assembling measurements I collected from the geothermal unit on a few mid-to-high-40s (°F) days:

Runtime: The thermostat is programmed with a nightly setback window of 10 hours & I recorded the geothermal unit running for about 15 hours each day, with a large off period during the night. The greater than 14h runtime may be explained by the temperature reaching the nighttime setpoint and/or the thermostats "adaptive" feature that tries to REACH an increased heating setpoint AT the programmed time.

Water demand: It seems 5-6000 gallons per day were used while I recorded (that's ~9ft cubed!). During the geothermal's operation, the distribution of flow rate looked somewhat like this:

5 GPM: 1%

6 GPM: 59%

7 GPM: 13%

8 GPM: 12%

9 GPM: 12%

10 GPM: 3%

Weighted average: ~6.8 GPM

The runtime duration will likely increase in colder weather and decrease in warmer weather. I suspect the water demand distribution will change based on the weather. Since I am not sure how or by how much these will change, I will treat the data I have as the average. With the following approximations, my yearly water demand for the geothermal alone is:

6 (months) x 30 (days/month) x 15 (hours/day) x 60 (minutes/hour) x 6.8 (gallons/minute) = 1.1 million gallons per year (for only 1/2 year usage!)

Approximations:

Geo operates 6 months per year (not much cooling is done in warmer weather)

30 days per month

Geo operates 15 hours per day on average

Geo demands an average of 6.8GPM when running

4) Larger pressure tank option

If I were to solve my short cycling by installing a bigger pressure tank, the pumps operating point (presently ~15 GPM) would not change. Since this operating point is near the limit of this pump, I assume the motor is operating at full service factor (1.590kW (~2.1HP) electrical input)). Thus, I estimate the yearly electricity cost to supply geothermal water is:

1,100,000gal x (1min/15gal) x (1h/60min) x 1.59kW x ($0.076/kWh) = $148

Of course, with normal household water use included, the total pumping electricity cost will be a little higher.

If I added a 119gal tank (for a combined drawdown of ~32 gallons (existing tank is 22gal, all operated 50/70PSI)), the pump would end up cycling ~105 times per day when the geothermal is used. This is close to (but does exceed) the 100 maximum number stated by Goulds/Xylem. The additional household water usage may increase or decrease the cycle count a little (depending on whether each use of household water brings the combined flow closer to or farther from half the ~15GPM max refill rate). I'm estimating a 119gal tank will cost roughly $1k and last 15 years, for an average cost of ~$67/yr.

When my existing motor/pump finally dies, I might be able to install a "3/4 HP" pump such as the Goulds/Xylem 10GS07 or 13GS07. I expect it will operate near full service factor as well, which will need electrical power of 1.335kW (~1.8HP)(according to data for the CentriPro M07412 motor).

The yearly electricity cost would then be $124. So, the larger pressure tank option would have a yearly cost of ~$215 (148+67) in the near term and potentially ~$191 (124+67) in the future (again, just considering geo water).

Edit Dec-10-2020: I made a mistake in the calculations of the above paragraph by neglecting that the pump curves of the 10GS07 & 13GS07 are different than my 10GS10. Replacing my current pump with either would result in a different operating point, and thus they would take different amounts of time to produce 1.1 million gallons. I still have not had a pumping level test performed on my well, but using the 10GS10 curve and working backwards from the observed 15 GPM operating point, it seems my system needs 140' of head. This should be predominantly static head, and thus won't change much as the flow rate changes. At 140' head, the 10GS07 would produce ~14 GPM, and the 13GS07 would produce ~15.4 GPM. The costs are then:

1,100,000gal x (1min/14gal) x (1h/60min) x 1.335kW x ($0.076/kWh) = $133 (10GS07)

1,100,000gal x (1min/15.4gal) x (1h/60min) x 1.335kW x ($0.076/kWh) = $121 (13GS07)

It's interesting that the larger pump actually ends up cheaper, and in fact it's probably even a tad cheaper than shown. The assumption that the 13GS07 would draw full service factor power is probably less accurate than the 10GS07/10GS10 case, because the 13GS07 is rated for up to 20GPM, and the 15.4 GPM operating point is significantly below that.

So, the larger pressure tank option would have a yearly cost of ~$215 in the near term and potentially ~$188-200 in the future (again, just considering geo water).

5) Pump change + CSV option

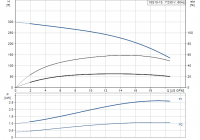

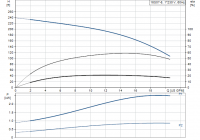

With a CSV installed, the pump will operate at whatever flow is demanded (above the minimum threshold), so a P_1 power curve is necessary to calculate electricity usage. Unfortunately, of the discussed pumps, the only P_1 curve I'm aware of is for the Grundfos 16S10-10 (see attached, it's the same data as the one attached to post #17, but with feet & GPM, and smaller because Grundfos changed their site). Reading values from that curve, I get:

5 GPM: 1.4kW

6 GPM: 1.5kW

7 GPM: 1.65kW

8 GPM: 1.75kW

9 GPM: 1.85kW

10 GPM: 2kW

The yearly electricity cost contribution of each flow rate is then:

5 GPM: $2.87 (6 x 30 x 15 x 0.01 x 1.4 x 0.076)

6 GPM: $181.60 (6 x 30 x 15 x 0.59 x 1.5 x 0.076)

7 GPM: $44.02 (6 x 30 x 15 x 0.13 x 1.65 x 0.076)

8 GPM: $43.09 (6 x 30 x 15 x 0.12 x 1.75 x 0.076)

9 GPM: $45.55 (6 x 30 x 15 x 0.12 x 1.85 x 0.076)

10 GPM: $12.31 (6 x 30 x 15 x 0.03 x 2 x 0.076)

For a total of: $329.44

Thus a "1 HP" Grundfos 16S10-10 is a costly choice, even before considering the cost of a CSV. Nonetheless, the use of a "3/4 HP" pump may make this option favorable.

6) Questions:

1) What manufacturers / brands / product lines of single-phase submersible pumps do you folks consider good quality, trouble-free & long lasting?

2) Of those, which will I likely be able to acquire P_1 power curves for?