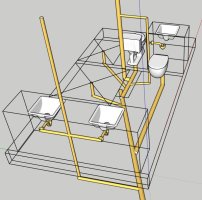

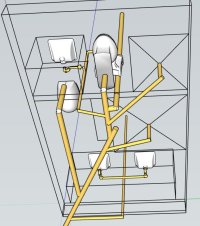

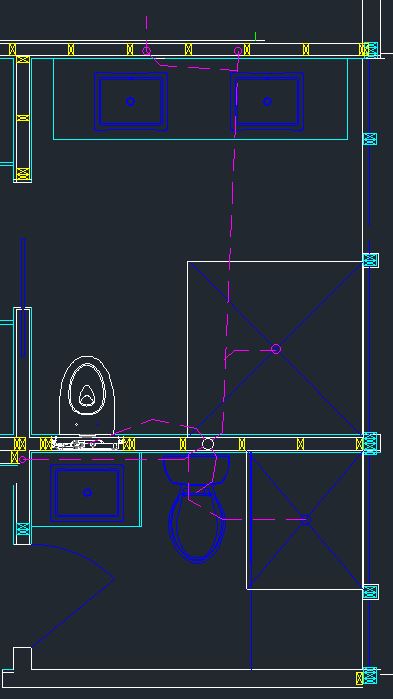

I have a 1963 ranch over a crawl space with back to back Master and Secondary bathrooms. It "was" all copper, but I had to rework the master layout quite a bit and I've now cut most of it out of the way except for the 3" vent and stack right behind the original toilet in bath 2. What was there, was a 4 way brass fitting 3x3x3x3x1.5x1.5. I was looking to more or less mimic that one joint in ABS and be able to tie back into the copper above and below that fitting. I see Nibco makes a

3" x 3" x 3" x 3" x 2" x 2" Hub ABS Double Sanitary Tee with Two 90° Inlets (583599)

but the new toilet location in the master makes this challenging. I'll wind up having to more or less make a sweeping 90d bend from both WC into it. Then I'll have to run new 2" drains from both showers into the 2" connection points. The sinks tie ie on both sides to more or less equal the load balancing at the Hub. I also have to add a studor on one of the master sinks to get venting on that leg. Any issues with what I've described or in the image attached?Attachments

Last edited: