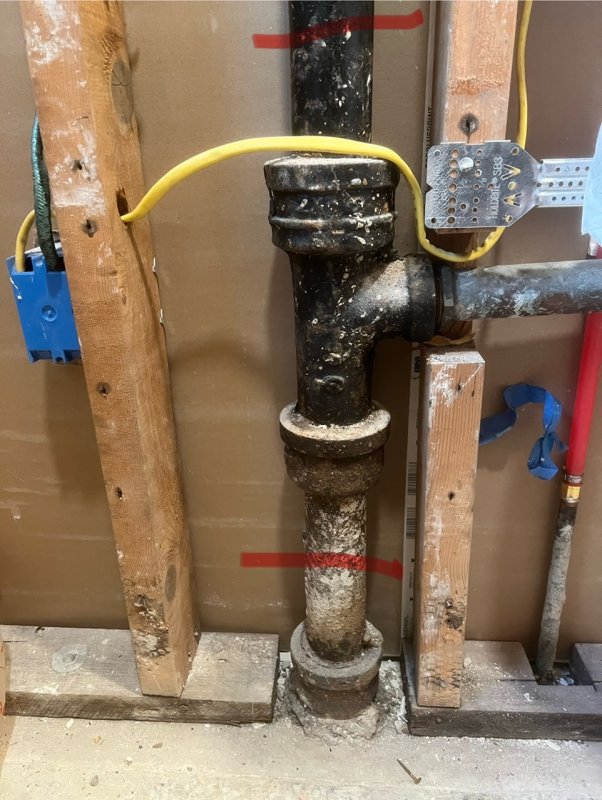

I have the wall opened up in my bathroom and I have what appears to be a 2" cast iron vent with a T and a 1.5" copper sink drain tied into it.

I was originally planning on just removing the copper sink drain and replacing it with PVC threaded into the cast iron T, but the position of the fitting being directly in the middle of a stud makes it a bit difficult to get a wrench on and also when I did, it didnt seem to budge even when putting some considerable force on it. I could heat it with a torch but the area is pretty tight and I dont want to damage anything, also I am not sure if I do remove it the threads in the T will be in good shape or not

I was thinking of just cutting a few inches above and below the T, and going with reinforced fernco couplers to integrate a PVC T

So I was thinking of adding a bit of blocking up towards the ceiling to fit a support bracket to the pipe, then taking a sawzaw with a metal blade to cut the pipe (is this a good idea or bad?), then going back and perhaps cleaning up the outside of the pipe with a bit of sandpaper and fitting a PVC "all hub" T with some stubs of PVC glued into it, and fit it in place with reinforced fernco couplers. Would I need to add any sealant on the outside of the cast iron pipe before putting the fernco on to insure there arent any leaks, or is just thoroughly cleaning/sanding/deburring the pipe good enough? Also what would be the best way to transition from the 2" outlet to a 1.5" for the sink drain, just a glued in fitting?

Attached is an image of what I am working with, the vertical pipe measures out to about 60mm OD (which appears to be 2" cast iron) and then the horizontal sink drain measures out a bit over 40mm OD (which appears to be 1.5" copper)

Thanks in advance.

I was originally planning on just removing the copper sink drain and replacing it with PVC threaded into the cast iron T, but the position of the fitting being directly in the middle of a stud makes it a bit difficult to get a wrench on and also when I did, it didnt seem to budge even when putting some considerable force on it. I could heat it with a torch but the area is pretty tight and I dont want to damage anything, also I am not sure if I do remove it the threads in the T will be in good shape or not

I was thinking of just cutting a few inches above and below the T, and going with reinforced fernco couplers to integrate a PVC T

So I was thinking of adding a bit of blocking up towards the ceiling to fit a support bracket to the pipe, then taking a sawzaw with a metal blade to cut the pipe (is this a good idea or bad?), then going back and perhaps cleaning up the outside of the pipe with a bit of sandpaper and fitting a PVC "all hub" T with some stubs of PVC glued into it, and fit it in place with reinforced fernco couplers. Would I need to add any sealant on the outside of the cast iron pipe before putting the fernco on to insure there arent any leaks, or is just thoroughly cleaning/sanding/deburring the pipe good enough? Also what would be the best way to transition from the 2" outlet to a 1.5" for the sink drain, just a glued in fitting?

Attached is an image of what I am working with, the vertical pipe measures out to about 60mm OD (which appears to be 2" cast iron) and then the horizontal sink drain measures out a bit over 40mm OD (which appears to be 1.5" copper)

Thanks in advance.