DuaneK

New Member

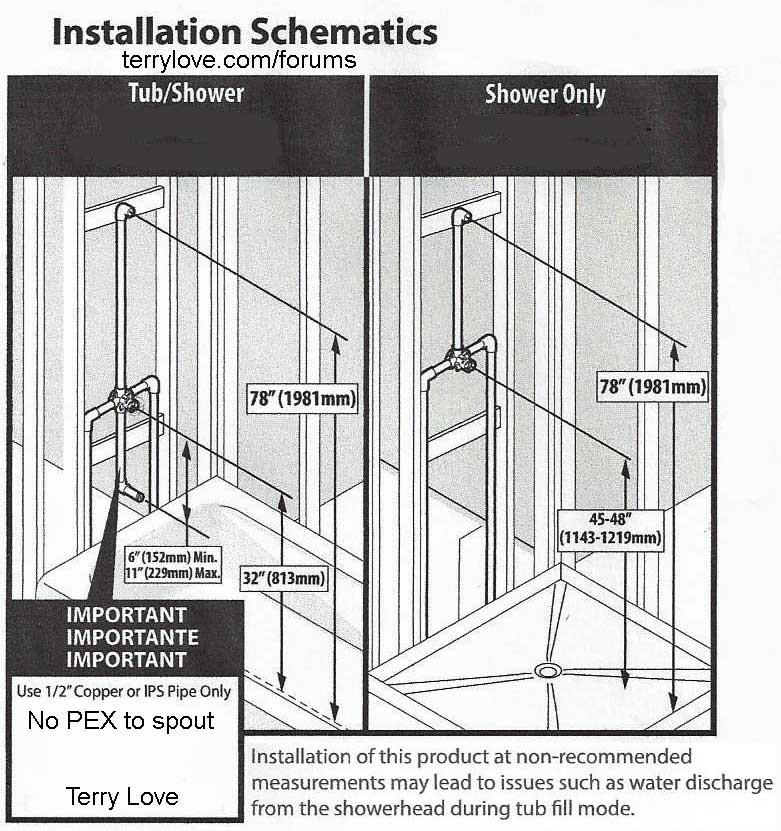

I will soon be installing a new Moen valve for our shower/tub. The instructions for a PEX install show the down pipe as a copper sweat joint and the other three as PEX. I'm not sure why they show this. The Spigot for the tub is a thread on. It would be easier for me if I could use a PEX to NPT drop elbow for this, like I plan to use on the shower head. Is there a reason why this is a bad idea and I should use straight copper instead. Then transition to NPT somewhere? I have a good PEX crimp tool and can frame a solid backing for the drop elbow.