WorldPeace

Member

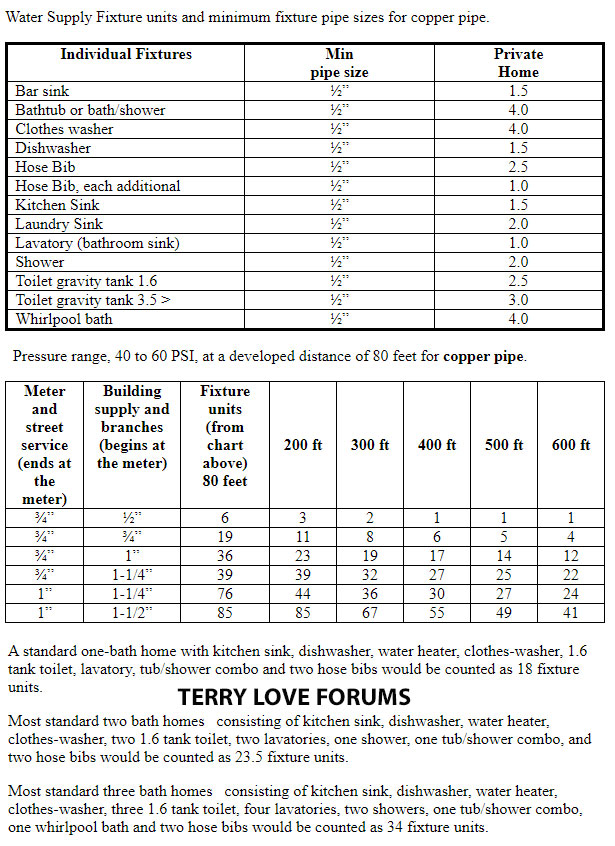

I've read conflicting information and I was wondering what the correct answer was. A pro here mentioned that they run as much 3/4'' pipe as possible, even running 3/4'' directly to bathroom tubs because code is just a minimum. They want to be safe.

However, wouldn't this have the opposite consequence?

I read that 1/2'' already has the capacity to supply more than 10 faucets running at the same time. But, by oversizing pipe, you will actually experience water pressure loss. If people happen to be using multiple fixtures at the same time, the increased pipe size will collectively lead to too much water loss so you experience the water pressure you were hoping to avoid.

I'm assuming that you need to make sure the pipe is not undersized so that it won't experience water pressure loss from a small decrease in pressure from the usage from other points of use. But, collectively, you need to make sure that all the pipes are not oversized so that there is not systematic loss in water pressure in the event that multiple people use it at once.

Is that correct?

However, wouldn't this have the opposite consequence?

I read that 1/2'' already has the capacity to supply more than 10 faucets running at the same time. But, by oversizing pipe, you will actually experience water pressure loss. If people happen to be using multiple fixtures at the same time, the increased pipe size will collectively lead to too much water loss so you experience the water pressure you were hoping to avoid.

I'm assuming that you need to make sure the pipe is not undersized so that it won't experience water pressure loss from a small decrease in pressure from the usage from other points of use. But, collectively, you need to make sure that all the pipes are not oversized so that there is not systematic loss in water pressure in the event that multiple people use it at once.

Is that correct?