Too Ambitious

Member

My current water heater is in my basement mechanical room. Can't put a hybrid there because there's not enough head room. I'm planning to move it to a storage room behind what used to be a carport (converted into sunroom). It's on a slab.

The plan is to route the plumbing through the rim joist & the (former) exterior wall. (There is already electrical going that way.)

Can I just pipe the condensate and drain pan drains through the wall and into the sump pit?

If so... I know that I can't drain the condensate directly into the drain pan, but can I combine the condensate and drain pan lines into a single pipe before they go through the wall?

Here are some pics:

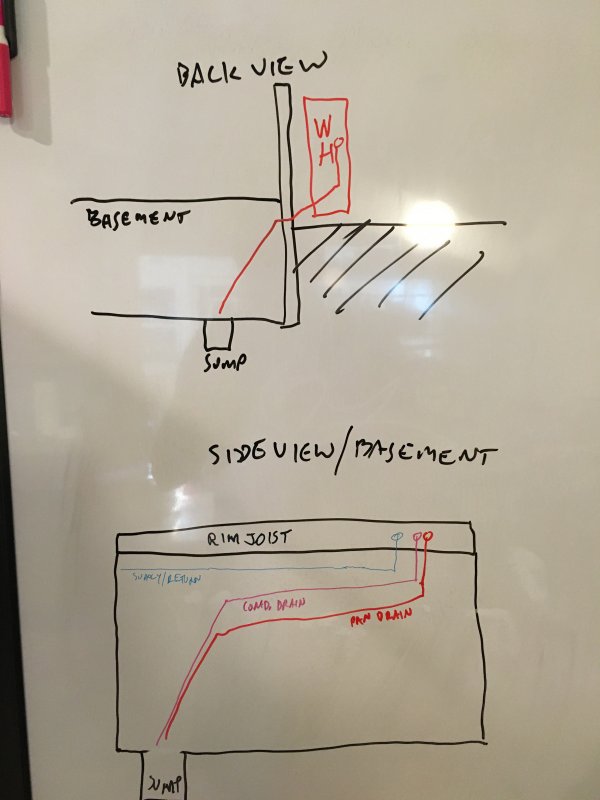

The plan:

This is the storage room where the new WH will go. Plan is to route the plumbing similar to the electrical.

Here's where the electrical is coming from. Planning to put a subpanel in the storage room rather than individual feeds.

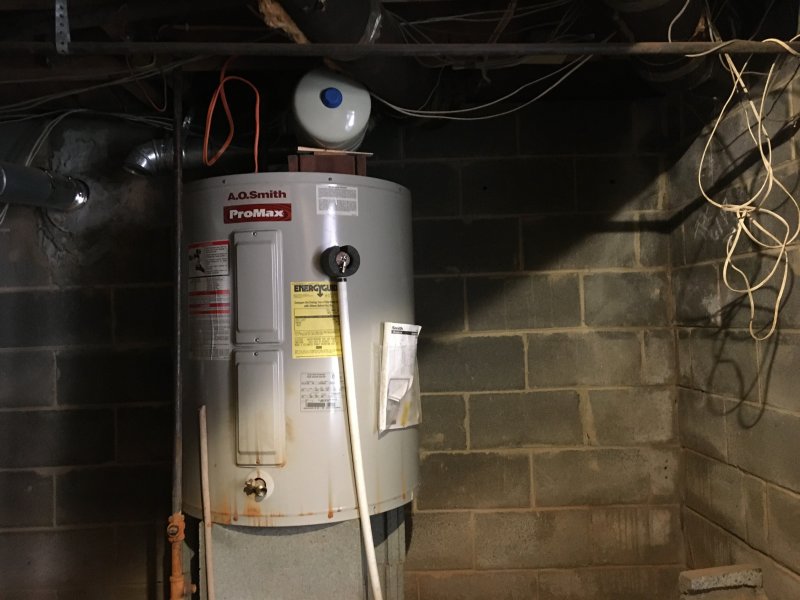

Current WH location, sump pit is to the left.

The plan is to route the plumbing through the rim joist & the (former) exterior wall. (There is already electrical going that way.)

Can I just pipe the condensate and drain pan drains through the wall and into the sump pit?

If so... I know that I can't drain the condensate directly into the drain pan, but can I combine the condensate and drain pan lines into a single pipe before they go through the wall?

Here are some pics:

The plan:

This is the storage room where the new WH will go. Plan is to route the plumbing similar to the electrical.

Here's where the electrical is coming from. Planning to put a subpanel in the storage room rather than individual feeds.

Current WH location, sump pit is to the left.