Glad you got the pump working. But I am afraid even a camera is just prolonging the inevitable digging.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New homeowner - well not working

- Thread starter Mandinca

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Mandinca

Member

Well I suppose the ground will be soft when I get close to the leak.....but being under a tree I think roots will be a big problem. If you think the most likely location for the leak is close to the pitless then I'll start there. I have a feeling that if it's not there....I'll have had enough

Sponsor

Paid Advertisement

Start at the wettest spot.

Mandinca

Member

Start at the wettest spot.

Will it be that noticeable at ground level if the leak is 4' down ?

It's a 7 gpm pump. That is significant if you are to replace the pump.It's a Grundfos 1/2 HP 230V 3 wire pump

A leak finding specialist might be able to find the leak with special equipment. But an alternative would be to have a new pipe trenched in. I don't know what that might cost.

Why do you suspect the path that you do? When you stuck the probe in, did you feel a discontinuity there? A fish tape used for pulling electric wires in conduit seems like a good probe.

If there is an elbow, that seems like another good place to get a disconnect.

If you have that pump out again, consider measuring the deadhead pressure. Expect about 178 psi. Only power the pump for a few seconds, because the pump is not being cooled by water flow.

Mandinca

Member

It's a 7 gpm pump. That is significant if you are to replace the pump.

A leak finding specialist might be able to find the leak with special equipment. But an alternative would be to have a new pipe trenched in. I don't know what that might cost.

Why do you suspect the path that you do? When you stuck the probe in, did you feel a discontinuity there? A fish tape used for pulling electric wires in conduit seems like a good probe.

If there is an elbow, that seems like another good place to get a disconnect.

If you have that pump out again, consider measuring the deadhead pressure. Expect about 178 psi. Only power the pump for a few seconds, because the pump is not being cooled by water flow.

I suspect that path as it's somewhat logical with the adapter at 3 o'clock and the tank location being where it is. I don't know if the tree was always there or if it was planted after the well was dug. I assume the well is as old as the house, around 1960.

So my guess is the pipe exits at 3 o'clock then makes a left turn toward 12 o'clock.

Martin Boring

In the Trades

Mandinca I couldn't see the pictures of the set up in the basement but it sound like you have the black plastic that came in rolls coming threw the basement slab that is feeding the water from the well. If that is what they used that stuff is pretty tough and unless you have a ton or sharp rocks in you area down were the pipe is the pipe is probably alright and the connection between the pitless and the black pipe probably failed. I have seen a lot of that old black plastic pipe in my area 40 or 50 years old still going but a fitting on one end or the other or where it got spliced failed. I would spend a couple evenings or a Saturday and dig down at the pitless and check that connection to see if it failed. I wouldn't run the well any more its not fun digging mud by hand.

Mandinca

Member

Yes, that's my plan at this point. With this pipe being in coils then it's entirely possible that no elbows were used, I'll try to run some sort of snake up the pipe from the pitless end to see if I find any evidence of dirt in the pipe. I've attached the picture of where the pipe enters the basement through the slab. I had to cut the hose between the entry point and the pressure switch as you can see. Once I had cut that hose I was able to get some flow from the pump but presumably not enough to get through the switch and fill the pressure tank. It certainly wasn't as much flow as I was getting when I unhooked the pitless adapter from the well casing and turned the pump on. So, even with very limited flow, my static water level dropped out of sight. I'll dig that hole.....

Thanks for your input.

Thanks for your input.

Mandinca

Member

So I dug down to the pitless adapter but there are so many huge roots in the way that I can't get access to it. Someone planted a tree right by the well and it's about 2' in diameter, the roots are 3-4 inches thick and there are a few in the way. I was able to find where the pipe exits the casing and there's an elbow right there which directs the underground line right under the tree. Genius.

With that said, I turned on the well and a small pool appeared by that elbow so that's where my leak is. I just can't get access to it because of all the roots. Disappointing but what can I do.

I'm going to sleep on it and have another go at digging out a big enough hole for access, if that doesn't work......

Plan B.

Run a new pipe 8" under the ground from the house to the well casing, put another pitless adapter near the top of the casing and use that instead. I can make the 8" buried pipe so I can blow it out for winter and then, in winter, move the pitless adapter from it's new location to it's old one so the drop pipe won't freeze.

At the house I was going to run that 8" deep pipe up the foundation and in through the wall, then connect it inside to the rest of the mechanicals.

With that said, I turned on the well and a small pool appeared by that elbow so that's where my leak is. I just can't get access to it because of all the roots. Disappointing but what can I do.

I'm going to sleep on it and have another go at digging out a big enough hole for access, if that doesn't work......

Plan B.

Run a new pipe 8" under the ground from the house to the well casing, put another pitless adapter near the top of the casing and use that instead. I can make the 8" buried pipe so I can blow it out for winter and then, in winter, move the pitless adapter from it's new location to it's old one so the drop pipe won't freeze.

At the house I was going to run that 8" deep pipe up the foundation and in through the wall, then connect it inside to the rest of the mechanicals.

I think you should be pleased. Yes, you have significant work ahead, but you found the problem with your first dig.With that said, I turned on the well and a small pool appeared by that elbow so that's where my leak is. I just can't get access to it because of all the roots. Disappointing but what can I do.

Is the pitless down below the frost line? There seems like a good chance that the pipe that is run is also below the frost line. I don't think you would want to give that up for a line 8 inches deep. Instead you can run a new section of pipe from the pitless to join that existing pipe that is good.

I would think a Sawzall with the right blade would be good for cutting those 4 inch roots. You may be able to put a chemical, such as copper sulfate crystals, by the roots to discourage the tree from re-growing and stressing your repaired pipe.

Do you want to keep the tree? Sounds like a capital offences to me.

Mandinca

Member

The pitless is down about 30" - I was told that the frost line in CT for deck posts (for example) is 42" so I don't know why the pitless is so shallow.

I would like to keep the original pipe but I just think it's going to be impossible to get to without endangering the tree.....and I want to keep the tree.

I'm concerned that those big roots are part of what is holding it up, it's quite close to the house and if it were to fall due to my root cutting that would be a problem ;-)

I've already cut a couple of the smaller roots (2") just to get to where I can feel the pitless in the hole I've dug. Feeling it and exposing it to the point where there is enough pipe to cut and replace are two very different things.

The hole I dug runs down beside the pitless then across to it. The biggest root is directly against the casing so is bang in the way. So if I reach down the hole then "underground" per se I can feel the elbow.

90% chance of rain today - I'll dig more tomorrow.

I would like to keep the original pipe but I just think it's going to be impossible to get to without endangering the tree.....and I want to keep the tree.

I'm concerned that those big roots are part of what is holding it up, it's quite close to the house and if it were to fall due to my root cutting that would be a problem ;-)

I've already cut a couple of the smaller roots (2") just to get to where I can feel the pitless in the hole I've dug. Feeling it and exposing it to the point where there is enough pipe to cut and replace are two very different things.

The hole I dug runs down beside the pitless then across to it. The biggest root is directly against the casing so is bang in the way. So if I reach down the hole then "underground" per se I can feel the elbow.

90% chance of rain today - I'll dig more tomorrow.

The tree roots will destroy your well. They can grow between the pipe and casing and even pull your pitless away from the casing. Roots can grow down the side of casing and into the water table and into the perferations. Seen many a well packed off with tree roots and had to tell the owner the bad news. The leak is the least of your problems. Getting rid of that tree and stopping the root growth is the hard part.

Mandinca

Member

The well itself seems fine, the large roots are close to ground level and I can see at least 20' down the well with no roots protruding into the casing.

As for the underground pipe, I have no idea if that has been compromised other than the leak at the pitless. My fear is that even if I fix the leak I can see, there may be others.

As for the underground pipe, I have no idea if that has been compromised other than the leak at the pitless. My fear is that even if I fix the leak I can see, there may be others.

Yes and leaks will be a continuing problem until you get rid of the tree. Got a big tree I am having to cut for the same reason.

Mandinca

Member

Yes and leaks will be a continuing problem until you get rid of the tree. Got a big tree I am having to cut for the same reason.

I had to give up on the underground pipe. I was able to dig out about 8 inches of the plastic pipe and had a really good view of it when I ran the well pump. The water wasn't leaking at the joint, it was still seeping out from the dirt where the pipe runs underground. I have no idea if the leak is still buried by another 6 inches or 2 feet of dirt. Either way, with the tree there, I can't get enough access.

The root between the spray bottle and the hole is about 6" thick, to give you an idea. The pitless was 2 feet below it and back under the dirt a bit more. Really hard to get to. To the right of the hole was another root that was probably 4" thick so I only had about a 15" opening to work with, down a 30" hole and across underground about another 8".

Fun.

So. Plan B.

I cut the plastic hose that goes underground, removed the brass fitting from between the pitless elbow and the black pipe (see attached) and put in another elbow so that the water goes left at the existing elbow then right through the new elbow.

I then added a short piece of plastic pipe horizontally, another elbow which now points upwards with a two foot piece of pipe attached to it to bring it to ground level. Unfortunately my phone died so I didn't get pictures of the final setup and I had to bury it so that the dirt pile didn't kill my grass.

Before I buried it I capped the new open end and turned the pump on to pressure test it for leaks. I got a slight drip from the newly installed elbow but I can live with that....one drip every two seconds.....and it was under pressure. I wanted to tighten it further but then it would have been pointing the wrong way. I added tape but that didn't help much so I'll have to live with that drip.

So for now I have a capped pipe at ground level that I can later tap into when I run another pipe underground to my house, up over the foundation and in through the siding where the pressure switch and tank is.

Attachments

One drip every two seconds just invites more tree roots. No matter how well you fix it the tree roots will tear it back out soon.

Mandinca

Member

Hello again all. I have found that the pitless adapter is leaking, looks very much like it's leaking at the o'ring. The problem is, it's about 4 feet down the well pipe so I can't actually reach it by hand. Digging out from the outside is impossible.

When I pull the pitless the part that is attached to the well pipe does not have the o'ring on it......so.....how do I get the o'ring out of the other part of hte pitless when it's so far down the pipe ? Any suggestions ?

Supposing I do get it out, how do I put another one in without dropping at least ten of them down the well first....

Any ideas ?

Thanks

When I pull the pitless the part that is attached to the well pipe does not have the o'ring on it......so.....how do I get the o'ring out of the other part of hte pitless when it's so far down the pipe ? Any suggestions ?

Supposing I do get it out, how do I put another one in without dropping at least ten of them down the well first....

Any ideas ?

Thanks

A missing or defective o-ring on the inside of the casing would cause water to drop down the well-- not into the yard.

If you are getting leaking to the yard, that would need fixing outside. Your photo of the pitless is not sharp. Does the pitless have a big hump outside of the casing, and is that hump welded in place?

Is that pitless picture of the same hole that the tree picture shows? Your well person is going to need to do some serious cutting of that tree, I would think.

When you lift the pitless inside, what does it look like?

If you are getting leaking to the yard, that would need fixing outside. Your photo of the pitless is not sharp. Does the pitless have a big hump outside of the casing, and is that hump welded in place?

Is that pitless picture of the same hole that the tree picture shows? Your well person is going to need to do some serious cutting of that tree, I would think.

When you lift the pitless inside, what does it look like?

Mandinca

Member

Hi Reach4, a bit more background.A missing or defective o-ring on the inside of the casing would cause water to drop down the well-- not into the yard.

If you are getting leaking to the yard, that would need fixing outside. Your photo of the pitless is not sharp. Does the pitless have a big hump outside of the casing, and is that hump welded in place?

Is that pitless picture of the same hole that the tree picture shows? Your well person is going to need to do some serious cutting of that tree, I would think.

When you lift the pitless inside, what does it look like?

I have city water but this well is still operational although disconnected indoors. When I tried to test it I found that everything worked but I got no water to the tank. So, I tested a few things and found everything was ok so I had to have a leak. Turns out the leak is in the pipe between the pitless and the house and is impossible to "repair". So, I dug down outside the casing and cut the pipe running to the house and instead replaced it with a capped "standpipe" at ground level right next to the well casing. The plan was to run a pipe above ground from the stand pipe to the tank to test it and to see if the well was sufficient to run an irrigation system. For that I need to know GPM, pressure etc to see if this is even feasible. Anyway, all of this was months ago and I just got back to it today. However, somehow I noticed that I left the well pump breaker on for a month (my electricity bill was much higher than usual) and I found this when I looked at the panel .... ugh. So.....if I had been pumping water into the capped pipe and the pitless o'ring was doing it's job then surely I would have a small swimming pool in my yard....but I didn't, which leads me to think that the pumped water must have been leaking at the pitless and down the inside of the casing. Odly enough the pump still worked despite being run for a month straight with who knows how much back pressure, when I pulled the pitless up and turned the pump on.....water came gushing out of the pitless from the well.

So, I have to at least replace the o'ring as I doubt it has ever been done and the well hasn't been touched for at least 15 years until I started trying to use it.

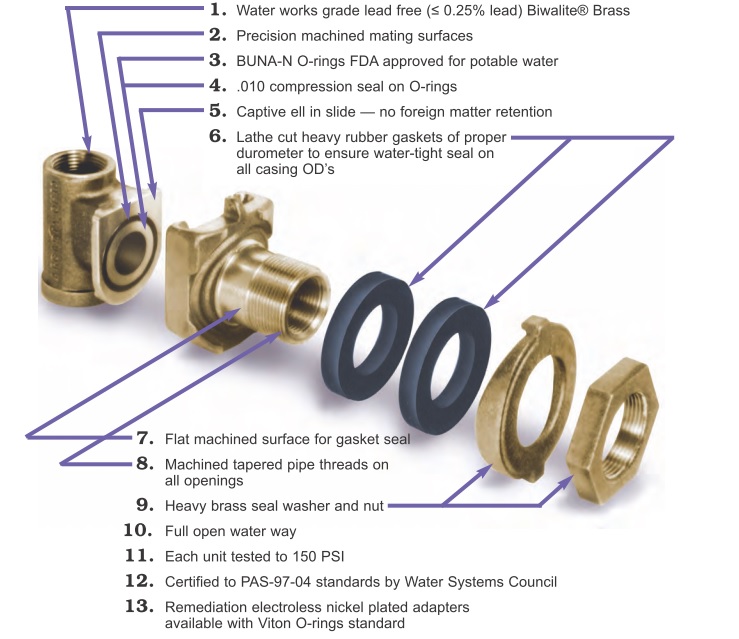

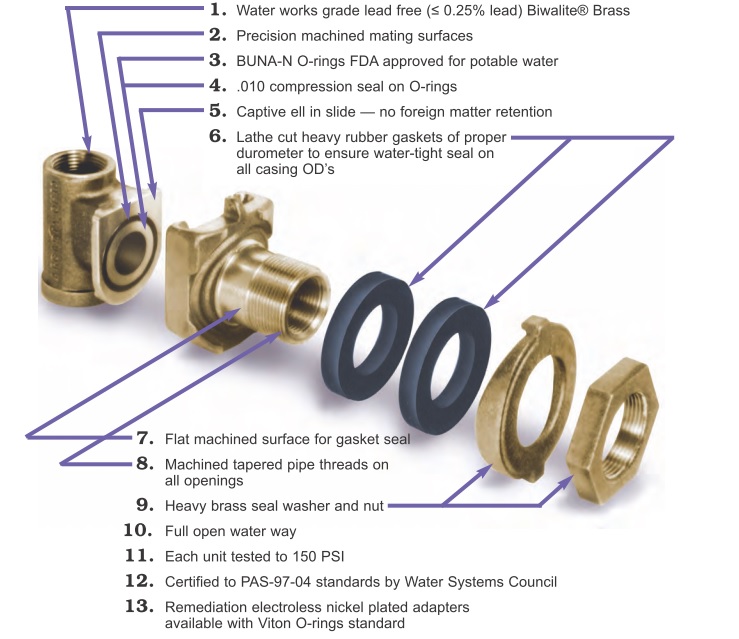

The pitless adapter I have looks something like this although I don't know the size for sure. I measured the size of the hole in the part attached to the well pipe and it was about 1 3/8" diameter but I assume the o'ring will need to be bigger than that.

Correction, I just went and pulled it again and it says Martinson B10 on it, so it's this one.

Martinson Pitless Adapter Well M-B10, M-B11, M-B12

Martinson Pitless Adapter Well M-B10, M-B11, M-B12

www.pillarsurplus.com

I searched for Martinson B10 and found this...

You were posting on this, thread post #28 you say this needs an L1 o'ring. Now I have looked everywhere and I can't find them for sale or even the specs of them. Do you know anywhere I can buy a few ?

So, assuming I can get some L1 o'rings how do you suggest I replace it given that it's out of reach down the well casing and I can't access it from outside the casing.

Presumably removing the old one will be relatively easy, use a pick on the end of a broom handle or something like that.

Putting the new one in place will be more difficult. I was thinking of lubing it up with some kind of grease and "gluing" it to a broom handle with the grease (or something like that) then gently lower it down the casing and press it into place.....maybe it goes first time or maybe I lose a few down the well until I succeed.

Do you have any other suggestions ?

Thanks for your help.

I am not a pro.

This is probably not your pitless, but it shows where the o-ring would be. At the end of the 2 arrow, tho the 3 and 4 callouts actually refer to the o-ring.

Valveman reports good luck getting an o-ring kit and selecting an o-ring from the kit. See #11 on https://terrylove.com/forums/index.php?threads/leaky-pitless-adapter.90975/

This is probably not your pitless, but it shows where the o-ring would be. At the end of the 2 arrow, tho the 3 and 4 callouts actually refer to the o-ring.

Valveman reports good luck getting an o-ring kit and selecting an o-ring from the kit. See #11 on https://terrylove.com/forums/index.php?threads/leaky-pitless-adapter.90975/

Similar threads

- Replies

- 2

- Views

- 461

- Replies

- 1

- Views

- 337

- Replies

- 15

- Views

- 1K

- Replies

- 19

- Views

- 1K