Kevin Bailey

New Member

Hello All -

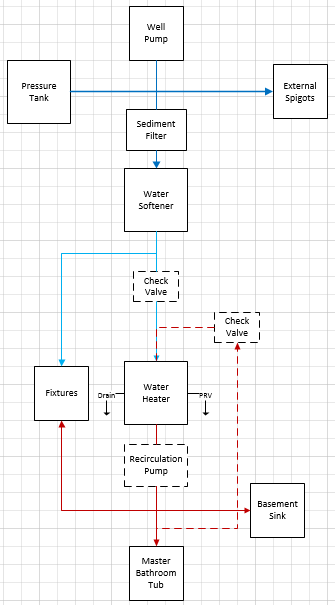

I'm looking to install a timer based recirculation pump for my hot water lines. My design is below.

A couple of things to note:

I'm looking to install a timer based recirculation pump for my hot water lines. My design is below.

A couple of things to note:

- The master bath and basement sink are the furthest fixtures from the WH

- The hot supply to the basement sink will be disconnected and used as the return

- The basement sink supply will be tapped off the master bathroom tub supply

- Cold water supplies are not shown for the master bath tub and basement sink, but implied

- Check valve flows are shown by the flow arrows

- Most of the recirculation pump install instructions want to push the hot back into the cold supply lines, I didn't want that due to the pressure tank and water softener

- Most dedicated return lines show the return to the WH drain, I didn't want that due to the possible sediment ruining the pump

- Not sure how to match up the ratings of the check valves with the pump

- Concerned that the Pressure Relief Valve (PRV) might dump all the return water when the pump is running

- Not entirely confident I need to connect the master bath tub and basement sink supplies, might be that I just need to connect one fixture and it will work magically

Last edited: