I have a fiberglass 80 gallon FlexLite FLS80D pressure tank with no diaphragm on a 200 ft deep well with a 1 hp Grundfos pump. It was installed by a professional well driller I paid $7,000 two and one half years ago who is now retired and doesn't what to come look at it. It took me a year and one half to build my house and move in so I have only been using my well for 6 months. Since I divorced my wife of 21 years for committing adultery with 5 men I am by myself and don't use much water.

Tapping the tank it sounds like it is 90% full of water. With just one cold water faucet open, the pump off, and the gauge at 50psi the water runs for 1minute and 23 seconds drops to 30psi then the pump runs for 8 seconds then shuts off for another 1 minute and 23 seconds. I have drained the tank several times with little change in the run time and I can't find any leaks.

I think with only an 8 second run time my pump will fail soon.

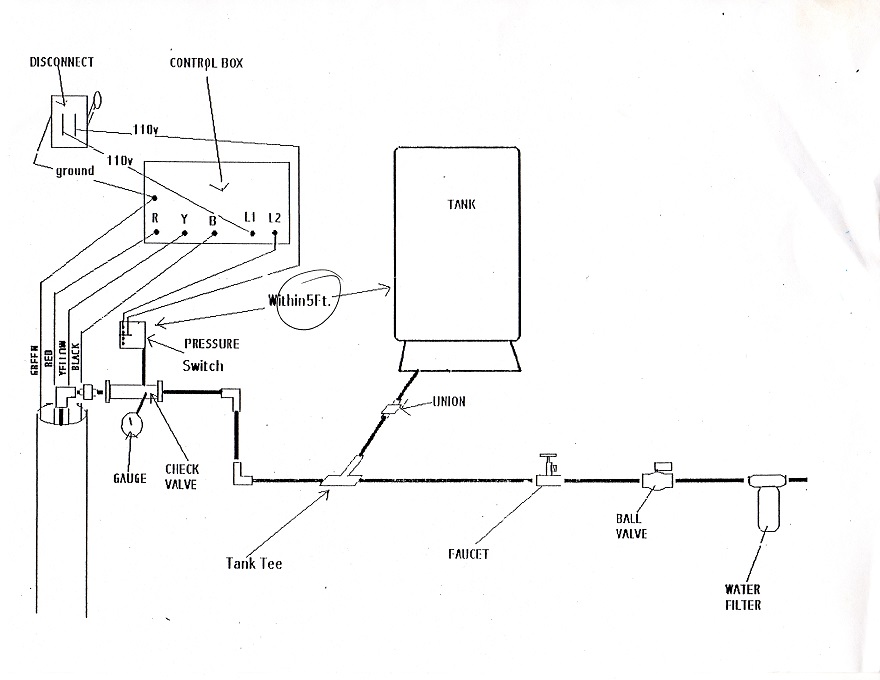

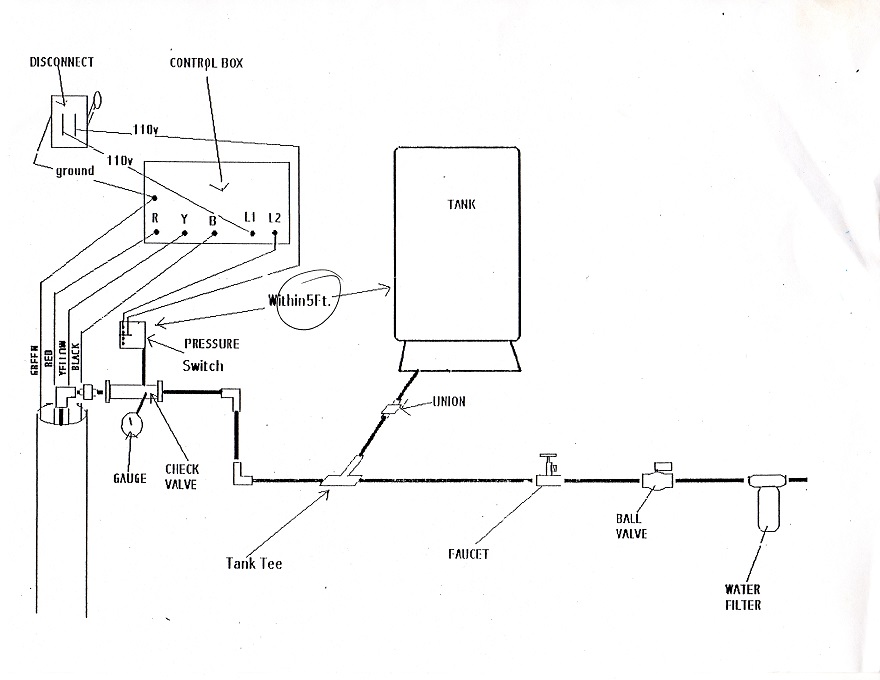

I am going to install an AO Smith (either a 36 or 86 gallon) tank with a diaphragm myself. I plan to follow this diagram unless I am advised otherwise.

My general question is what do I need to change to go from a pressure tank without a diaphragm to one with a diaphragm?

1. Do in need to replace the brass fitting which has the snifter/schrader valve and the pressure switch on it to eliminate the snifter/schrader valve?

2. Do I need to eliminate the weep hole I saw the well driller drill through the well pipe for air intake about 12 feet down?

3. I plan to get 2 friends to help me pull up the well pipe so I can eliminate the weep hole. The well driller installed the pump with 2 helpers and no platform or pipe pulling rig.

Should I just glue the weep hole shut or should I cut the pipe across the weep hole and glue in a coupling?

If need to install a coupling to eliminate the weep hole do they make one of a higher schedule like the well pipe is. It's the high grade schedule pipe that has built in couplings. I would hate for the well pipe and pump to drop.

Thanks in advance to anyone who advises me. May God bless you.

Tapping the tank it sounds like it is 90% full of water. With just one cold water faucet open, the pump off, and the gauge at 50psi the water runs for 1minute and 23 seconds drops to 30psi then the pump runs for 8 seconds then shuts off for another 1 minute and 23 seconds. I have drained the tank several times with little change in the run time and I can't find any leaks.

I think with only an 8 second run time my pump will fail soon.

I am going to install an AO Smith (either a 36 or 86 gallon) tank with a diaphragm myself. I plan to follow this diagram unless I am advised otherwise.

My general question is what do I need to change to go from a pressure tank without a diaphragm to one with a diaphragm?

1. Do in need to replace the brass fitting which has the snifter/schrader valve and the pressure switch on it to eliminate the snifter/schrader valve?

2. Do I need to eliminate the weep hole I saw the well driller drill through the well pipe for air intake about 12 feet down?

3. I plan to get 2 friends to help me pull up the well pipe so I can eliminate the weep hole. The well driller installed the pump with 2 helpers and no platform or pipe pulling rig.

Should I just glue the weep hole shut or should I cut the pipe across the weep hole and glue in a coupling?

If need to install a coupling to eliminate the weep hole do they make one of a higher schedule like the well pipe is. It's the high grade schedule pipe that has built in couplings. I would hate for the well pipe and pump to drop.

Thanks in advance to anyone who advises me. May God bless you.