Slugboy6000

Member

Hello, I'm looking for a way to drain my plumbing back into my well.

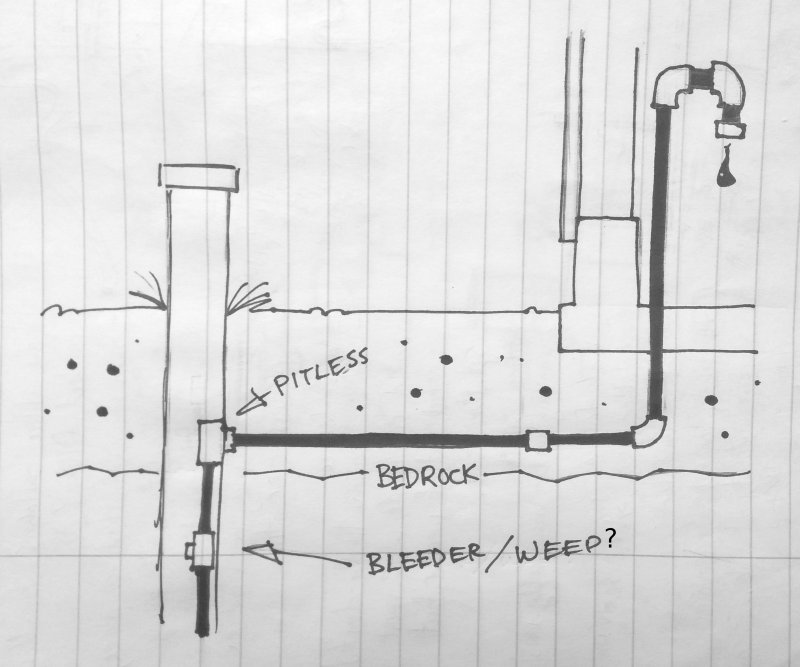

It's a simple setup where I'd like to manually control my submersible well pump so that I can fill an open tank with water in freezing temps and let the plumbing drain itself between uses. I'm assuming that the bleeder type valves used in drain-back systems don't work without pressure and wonder if instead a weep hole in the drop pipe would be appropriate in this situation?

My pitless adapter is only 12" below grade due to bedrock, the supply line is insulated and the outlet emerges 8' away into an uninsulated shed.

Thanks

It's a simple setup where I'd like to manually control my submersible well pump so that I can fill an open tank with water in freezing temps and let the plumbing drain itself between uses. I'm assuming that the bleeder type valves used in drain-back systems don't work without pressure and wonder if instead a weep hole in the drop pipe would be appropriate in this situation?

My pitless adapter is only 12" below grade due to bedrock, the supply line is insulated and the outlet emerges 8' away into an uninsulated shed.

Thanks

Last edited: