Hello all -

First timer here. I'm not a complete newbie, but I do have a question about poly pipe.

I recently replaced an Irritrol valve and the PCV leading up to it on the supply side. Due to that, the value is now slightly closer to the poly pipe that on the output side. Because of that the current piece of poly pipe on that side would no longer fit. I cut a little off so it would fit securely on the barbed connection.

Well I got a little too overzealous and cut too much. Now, it leaks from the barbed connection when I turn on that zone. A foot down the line from the value I have my first barbed T that goes to a head. So, now I have to try to wedge about a 10" new section of poly between the value and the T.

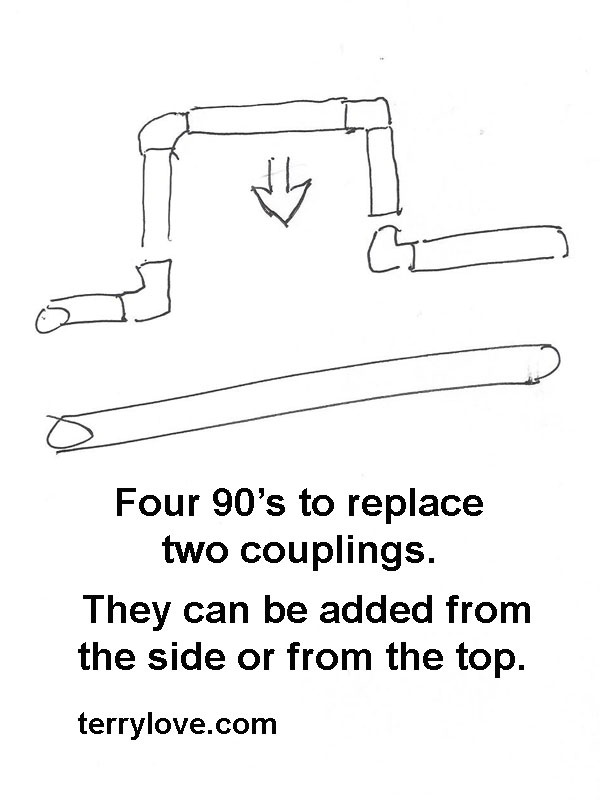

After all that, here's my question. Since that little bit of poly i need to install isn't exactly flexible, how in the world do I get the new short piece of poly around both barbs? I have no play on the valve side, obviously. Do I need to trench back on the other side to get some flexibility? If that's what I have to do, that's fine. I just thought I'd ask if there any other possibilities before I go through that hassle.

Thanks in advance !

Brett

First timer here. I'm not a complete newbie, but I do have a question about poly pipe.

I recently replaced an Irritrol valve and the PCV leading up to it on the supply side. Due to that, the value is now slightly closer to the poly pipe that on the output side. Because of that the current piece of poly pipe on that side would no longer fit. I cut a little off so it would fit securely on the barbed connection.

Well I got a little too overzealous and cut too much. Now, it leaks from the barbed connection when I turn on that zone. A foot down the line from the value I have my first barbed T that goes to a head. So, now I have to try to wedge about a 10" new section of poly between the value and the T.

After all that, here's my question. Since that little bit of poly i need to install isn't exactly flexible, how in the world do I get the new short piece of poly around both barbs? I have no play on the valve side, obviously. Do I need to trench back on the other side to get some flexibility? If that's what I have to do, that's fine. I just thought I'd ask if there any other possibilities before I go through that hassle.

Thanks in advance !

Brett