Friolator

New Member

We've had an ongoing issue that I think I've finally narrowed down a bit. Every once in a while, our Buderus GB142 reports water pressure that's too low, and won't come on. Thus, we come home to a cold house, or like this past weekend when we were away, I get an email from the thermostat that it's 55 degrees inside, and have to have a friend with a key run over to the house to reset it.

When the water pressure is too low, it's reporting values along the lines of 3PSI. ("P03" flashing on the control panel)

The solution to this problem has always been simple: power cycle the boiler. As the boiler initializes, you can watch the pressure rise a bit, usually by 1-2 PSI, then when the circulator pump comes on momentarily, it spikes up again, and will eventually return to around 15PSI. It can stay like this for weeks or months before dropping again.

What I have noticed is that there's a pattern: the pressure only drops when the outside temperature rises for a couple of days. There are fewer calls for heat in this case, and the pressure seems to slowly drop until it's so low the boiler won't fire. Power cycling it always seems to reset it as described above.

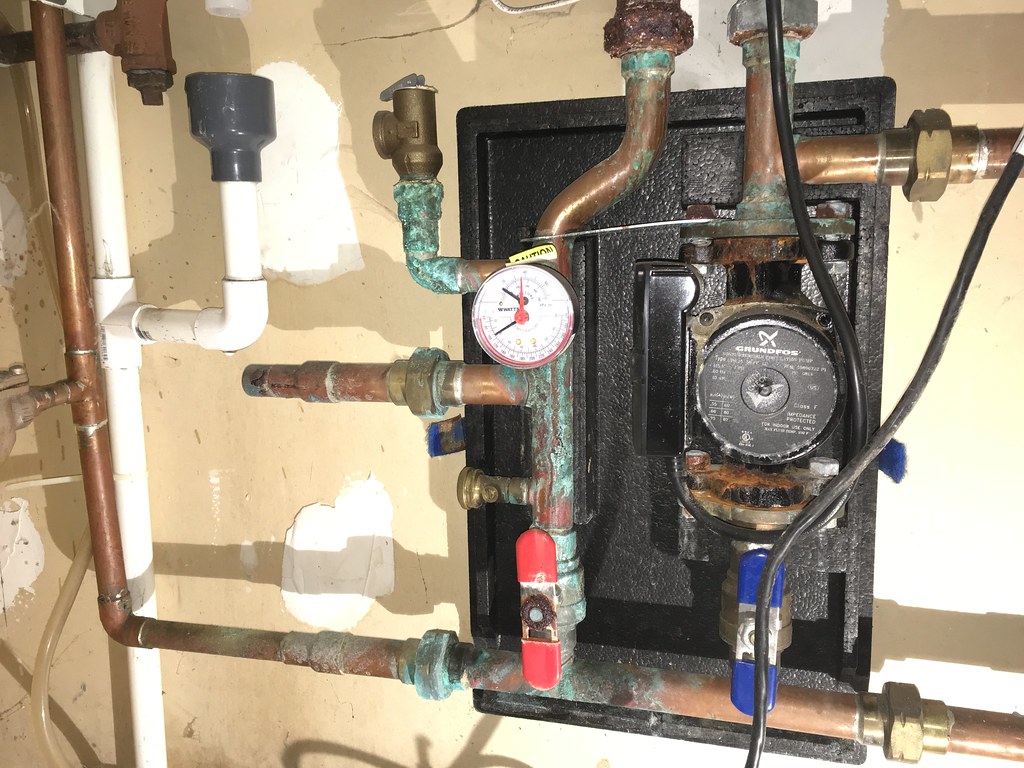

The system is pretty simple: single zone, heat only (no domestic hot water). There's a single circulator pump and a small expansion tank (which may have been re-used by the installer 12 years ago, when the old system was upgraded, I suspect).

The house itself is on Boston city water, and I would argue the overall system pressure is actually too high (we blow through a lot of sink gaskets because of it), and more than once I've had the kitchen faucet in just the wrong spot and the water bounced off a pot right into my face. I've been considering adding a pressure reducing valve for the whole house because of those issues, but have held off until this heating pressure thing is dealt with.

So, any ideas? Where should I start looking? Could an old expansion tank be the culprit?

Also, please enjoy a relevant musical selection.

When the water pressure is too low, it's reporting values along the lines of 3PSI. ("P03" flashing on the control panel)

The solution to this problem has always been simple: power cycle the boiler. As the boiler initializes, you can watch the pressure rise a bit, usually by 1-2 PSI, then when the circulator pump comes on momentarily, it spikes up again, and will eventually return to around 15PSI. It can stay like this for weeks or months before dropping again.

What I have noticed is that there's a pattern: the pressure only drops when the outside temperature rises for a couple of days. There are fewer calls for heat in this case, and the pressure seems to slowly drop until it's so low the boiler won't fire. Power cycling it always seems to reset it as described above.

The system is pretty simple: single zone, heat only (no domestic hot water). There's a single circulator pump and a small expansion tank (which may have been re-used by the installer 12 years ago, when the old system was upgraded, I suspect).

The house itself is on Boston city water, and I would argue the overall system pressure is actually too high (we blow through a lot of sink gaskets because of it), and more than once I've had the kitchen faucet in just the wrong spot and the water bounced off a pot right into my face. I've been considering adding a pressure reducing valve for the whole house because of those issues, but have held off until this heating pressure thing is dealt with.

So, any ideas? Where should I start looking? Could an old expansion tank be the culprit?

Also, please enjoy a relevant musical selection.