diy-montana

New Member

Hey all,

I’m in the framing portion of a shower-rebuild, and wanted to make sure I account for plumbing considerations before I get too far. Attached is a link to photo of what I’m aiming for. Its a corner 4x6 shower, with a door off a half-wall. I intend to put a standard showerhead as well as a handheld shower on the same wall. I’ll be plumbing with ½ inch crimp-style PexB, branching off of ¾’’ in the crawlspace.

In order to be able to turn on the shower without getting wet, I’m hoping to install the mixing valve on the half-wall near the entrance. The bathroom is above a crawlspace with easy access, so it will be easy to bring supply lines up into a stud bay of the half-wall. I have a couple questions:

Thanks for all the help!

I’m in the framing portion of a shower-rebuild, and wanted to make sure I account for plumbing considerations before I get too far. Attached is a link to photo of what I’m aiming for. Its a corner 4x6 shower, with a door off a half-wall. I intend to put a standard showerhead as well as a handheld shower on the same wall. I’ll be plumbing with ½ inch crimp-style PexB, branching off of ¾’’ in the crawlspace.

In order to be able to turn on the shower without getting wet, I’m hoping to install the mixing valve on the half-wall near the entrance. The bathroom is above a crawlspace with easy access, so it will be easy to bring supply lines up into a stud bay of the half-wall. I have a couple questions:

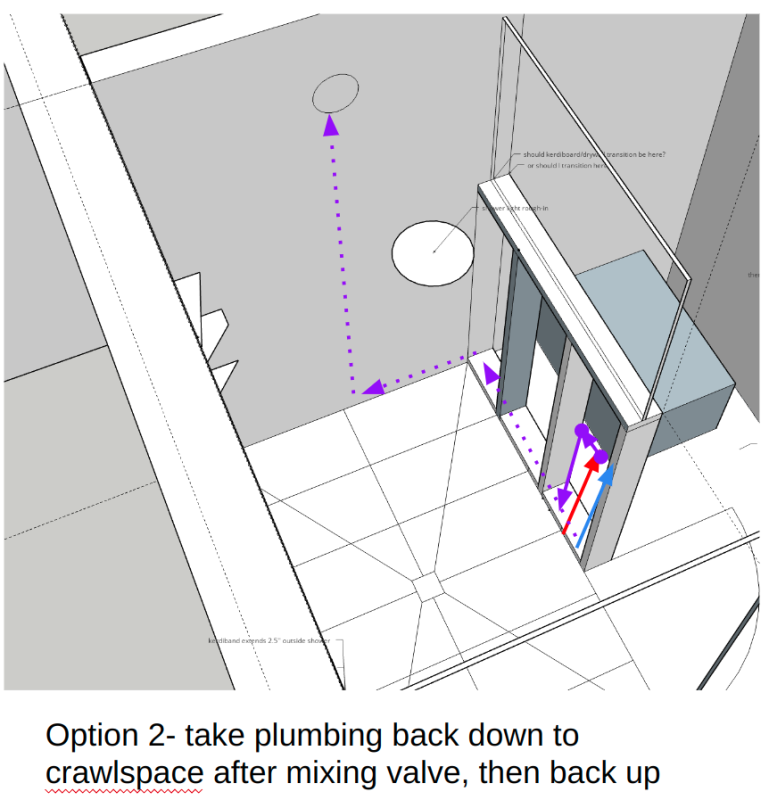

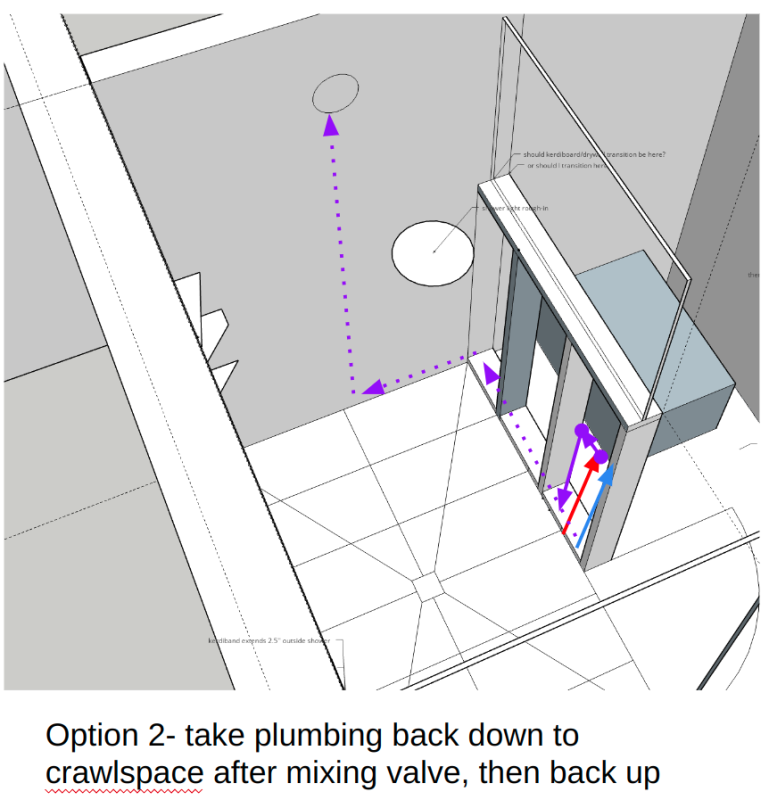

- I’m assuming it will be easier to run the outlet of the valve back into the crawl space, over to the showerhead wall, and up through the bottom plate of that wall, rather than running it through the vertical studs, and then making a right-angle through the end of the half-wall, the blocking the half-wall is secured to. Is this a good assumption? The half-wall will be framed with 2x4 not 2x6, and I’m taking steps to make sure it is quite sturdy, and I don’t want to compromise the corner by having a huge notch to accomplish the right-angle.

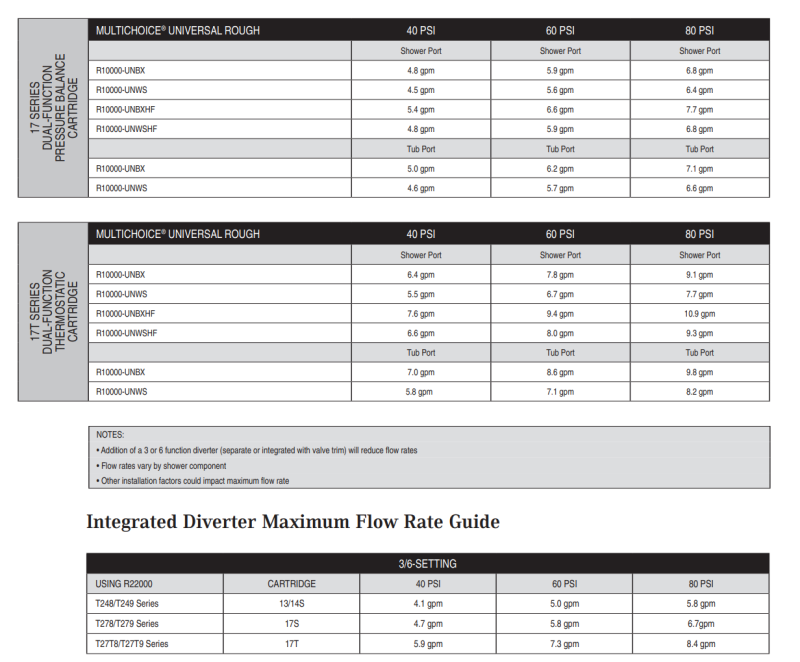

- My initial plan is to either use a Delta R10000 mixing valve on the half wall and place a 3-setting diverter on the shower-wall, or using one of the integrated R22000 valves + diverters on the half wall. The advantage of the R22000 is that it would make tiling easier since there would be one fewer penetration. Have people had good results with the flow/pressure of the R22000 in feeding two fixtures simultaneously? I’m on a private home-well, and I just checked, and my pressure tank brings it up to 55 psi, and kicks on when it drops to about 40 psi. I’m assuming the R22000 is designed for this, but I want to make sure people have had good experiences. They have a “high flow” version of the R10000, but I haven’t seen the same for the R22000. I actually just did the price math and it definitely does *NOT* make sense to do a R10000 and 3-setting diverter. The prices on the standalone diverters are so high it would make more sense to do two separate R10000s, and just put the controls for the handheld shower on the shower wall. So the choice would be between an integrated R22000, or two separate R10000 - HF. Based on the below chart, assuming 40 psi, each pressure balancing R10000 would be able to deliver 5.4 gpm, while the R22000 would be limited to 4.7 gpm. With each fixture actually limited to 2.5 gpm, I imagine the shower experience would be limited by pressure outlet, rather than gpm, right?

- Assuming the answer to #1 is “yes, it makes sense to run the outlet of the valve back down to the crawlspace”, is it OK to install the R10000/R22000 valves upside-down to make this easier? I imagine the valve itself would function correctly, but not sure if the trim knobs would still be intuitive, or would look weird?

Thanks for all the help!