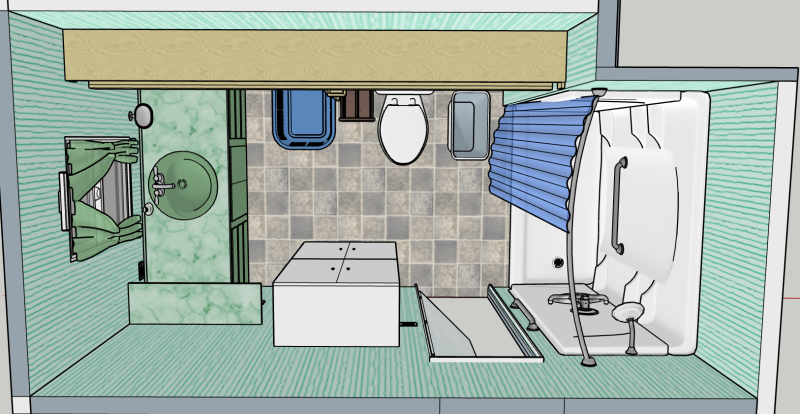

So, I adjusted the sketchup image of my mother's bathroom to show closer to the current color of the sink, walls, cabinets, shelves, etc. But the shower, curtain rod, etc are more along the lines of what will be in the bathroom when we renovate & I added a light over the vanity. Mom nixed the idea of the nicer light in her bathroom so I found an LED one that can stuck to the wall above the window. I'll have to get my left shoulder working again to have enough mobility to reach up. I also need to compensate for a weird detail near the ceiling on all of the walls.

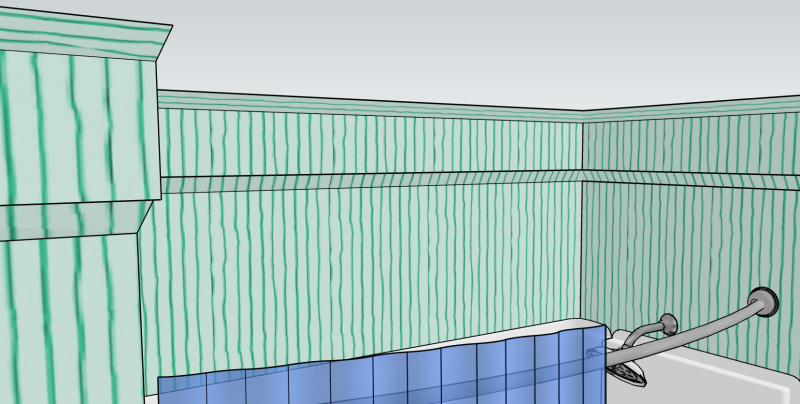

There is a strip going up diagonally and then another smaller strip horizontal and then it goes straight up a few inches and then diagonal again. This poses a problem over the shower if I want to run cementboard up if I don't want to tear out that detail above the shower area. I suppose I could remove it above the shower, but that would take more cutting. So, I'm thinking of just running the cementboard up to the lower angled piece and adding some sort of trim or just caulking.

I did my best approximation. I don't have exact measurements so this is just guessing.

I suppose I could try to chamfer the back of the cementboard where it will meet the lower angled trim.

Any other ideas or suggestions?

There is a strip going up diagonally and then another smaller strip horizontal and then it goes straight up a few inches and then diagonal again. This poses a problem over the shower if I want to run cementboard up if I don't want to tear out that detail above the shower area. I suppose I could remove it above the shower, but that would take more cutting. So, I'm thinking of just running the cementboard up to the lower angled piece and adding some sort of trim or just caulking.

I did my best approximation. I don't have exact measurements so this is just guessing.

I suppose I could try to chamfer the back of the cementboard where it will meet the lower angled trim.

Any other ideas or suggestions?