TechInstructor

Member

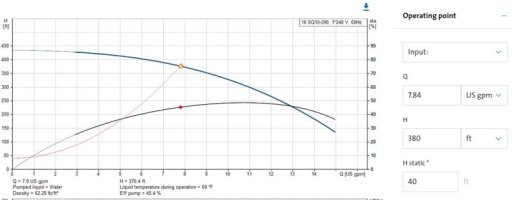

We installed a new pump in our well. It is a Grundfos 10SQ10-290 - 10 gpm 1 hp. Our well is 420’ deep - the pump sits at 380’ - the static water level is 40’ and the well flow is 2 gpm. We also installed a new pressure tank. It is a 22g CAD2 Flex-Lite composite tank. There is a new Square D 40/60 pressure switch with low pressure cut-off at the tank. This new set-up has only been in place for 5 days and since then we’ve had the low pressure cut-off engage several times.

We ran the same model pressure switch with our old pump (a Myers Predator 5 gpm 1 hp) and a very small 5 gallon pressure tank. We installed that particular switch in order to have protection for the pump should the well, with its low flow, be overdrawn. In the 14 years we ran that system, we only had the switch cut off once or twice and that was when two outlets were on full blast simultaneously.

Back to my current issue:

The low pressure cut-off switch shut off at these times:

Our well holds almost 500 gallons of water in the 6" casing (water from 40 - 380 ft) so none of these situations that have occurred should have been because the water level in the well was too low. While I was draining water out, I was being careful to have times when no water was running to allow for recovery.

The Grundfos pump is supposed to have built in protection to make it shut off if it senses the water column getting too low. In light of that do I even need to use a switch with low pressure cut off?

We ran the same model pressure switch with our old pump (a Myers Predator 5 gpm 1 hp) and a very small 5 gallon pressure tank. We installed that particular switch in order to have protection for the pump should the well, with its low flow, be overdrawn. In the 14 years we ran that system, we only had the switch cut off once or twice and that was when two outlets were on full blast simultaneously.

Back to my current issue:

The low pressure cut-off switch shut off at these times:

- Thursday 5/11 -- When trying to drain the chlorine from the well we were running a hose from the well boiler drain on full flow (about 8 gpm). A sink faucet was also on full (I was unaware of this). After this, I noticed the sediment filter at the house (5 micron pleated) was getting full, so I cleaned it.

- Friday 5/12 – Still trying to drain chlorine, I was running a faucet on full (about 3 gpm). After running for somewhere between 60 and 90 minutes, the cut-off switch shut off. The sediment filter was very full of fine and not so fine particles so the flow most likely became very slow before the pump was shut off. I installed a new filter. Afterwards I continued running water intermittently to drain chlorine.

- Saturday 5/13 - I don’t think the switch kicked in the pump off on this day. We continued to run water for normal use and periodically cleaned the sediment filter.

- Sunday 5/14 – Installed another new sediment filter. When water was turned back on after installing the filter, the low pressure switch kicked the pump off. The same thing happened hours later when the water was turned off again to clean the filter. We thought it might have something to do with getting air in the line.

- Monday 5/15 – I had run less than 30 gallons of water over about 90 minutes with intermittent use (washing dishes, filling a 5 gallon water can, starting the washing machine). I was filling a plastic dish pan with water (about 2 gallon size) for the second time when the water pressure suddenly dropped. The low pressure switch had again kicked in but this time under normal use conditions.

Our well holds almost 500 gallons of water in the 6" casing (water from 40 - 380 ft) so none of these situations that have occurred should have been because the water level in the well was too low. While I was draining water out, I was being careful to have times when no water was running to allow for recovery.

The Grundfos pump is supposed to have built in protection to make it shut off if it senses the water column getting too low. In light of that do I even need to use a switch with low pressure cut off?