I recently got a Katalox Light filter

2510SXT Fleck

When I watch it backwash which I can kind of do through the white wrapped tank, only like one side of the katalox is getting lifted and its only being lifted like 3-4 inches up sort of bubbling/flying up. Does that seem right or should the whole tank be mixing or more than that.

If it is hardening in the bottom does anyone have a recommendation to break it up? I could disconnect and then spray water in or something idk.

I tested for 7GPM which is all I should need for my tank...but I feel like it is just not getting lift.

I don't have any iron...but still seems pretty bad and concerned its going to freeze up. I have it BW every night instead of 2-3 days just to try to limit this but would like to not have to do this.

I recently got a Katalox Light filter

2510SXT Fleck

When I watch it backwash which I can kind of do through the white wrapped tank, only like one side of the katalox is getting lifted and its only being lifted like 3-4 inches up sort of bubbling/flying up. Does that seem right or should the whole tank be mixing or more than that.

If it is hardening in the bottom does anyone have a recommendation to break it up? I could disconnect and then spray water in or something idk.

I tested for 7GPM which is all I should need for my tank...but I feel like it is just not getting lift.

I don't have any iron...but still seems pretty bad and concerned its going to freeze up. I have it BW every night instead of 2-3 days just to try to limit this but would like to not have to do this.

I'm a brand new member and not really sure where to post.

I too recently bought a Katalox Light filter.

12 by 52 inch tank

2 cubic feet of Katalox

2510SXT Fleck.

I've been on a well for over 30 years.

I limit my flow rate to an average 1.5 gpm, it's about 1gpm at 20psi and around 2gpm at 40psi.

I can do this because I have all my filtered water go to a 2500 gallon tank right behind the pumphouse.

I then use a 1.5hp pump/motor to take the water from the 2500 gal tank and pump up my pressure tank and send the water to the house.

I have about 7.5ppm Iron with Iron bacteria so I chlorinate my well water with chlorine and have it go to a 120 gal mixing tank before going to the iron filter.

I couldn't see backwashing my filters with the brown water that comes out of my mixing tank so through 1 inch solenoid valves, I backwash my filters with the filtered water from the 2500 gal tank. The pressure tank is set to 40 to 60 psi.

It's all automatic. When a filter, or the water softener, starts to backwash/ regen, through relays, the valve that sends the now filtered water to the 2500 gal tank closes and the appropriate solenoid to take the filtered water from the tank opens and backwashes the filter.

I recently checked the backwash flowrate to the new Katalox filter from the dlfc drain line using a 20 gal bucket and stopwatch.

I backwash the katalox filter for 14 minutes. It took 95 seconds to fill 20 gals. The thing is it does that for at least 10 minutes of that 14 minutes because once the pump starts, it doesn't shut off until the backwash is finished and it usually hods at about 56 psi. It used to shutoff before I removed the 7gpm button from the dlfc. I removed it on the advice of the company who sold it to me because that's always the first thing anyone thinks is the problem.

Anyway, that 95 seconds comes out to be 12.6 gpm. I have one inch pvc going right into the control valve. form the pump which is in the same pumphouse a few feet away.

And the problem is...with chlorinated water going through a 120 gal mixing tank and 2 cubic feet of Katalox Light at an average

of 1.5 gpm and being backwashed at 12.6 gpm with filtered water, I have brown water coming out the hose bib on the output of the katalox filter.

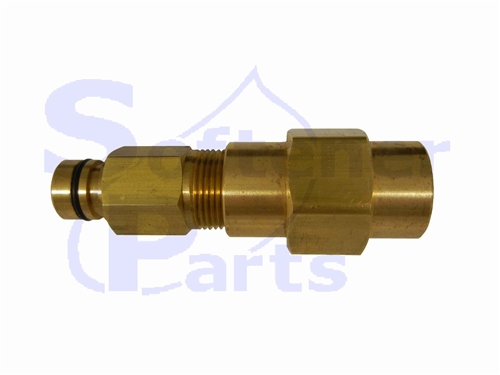

When I received the 2510, I noticed that there was a break at the base of the control valve but not near the o ring for the distributor tube. I didn't think it would cause a problem. I emailed a picture of this to tech support and asked them could it be causing my problem. I attached the photo here.

As I said, first they wanted me to remove the dlfc button, which I did but I still get brown water out the hose bib.

Then they mailed me a new base for the 2510.

They told me to first remove the clamp at the base and remove the control valve which I did.

But when I started to unscrew the base I noticed that the distributor tube is turning with it and if I keep turning I will lift the tube up. So I stopped and called tech support. waiting for their call now.

As tight as that o ring is grabbing that tube, I still can't believe that's the problem, though I wish it was.

I posted here because even though I have 12.6 gpm backwash rate, like iblackihiawk, when I look through the tank during backwash I don't see the whole bed lift up. It goes up pretty high around the edges. Is the whole bed supposed to expand like the videos we see of the vortech?

By the end of the backwash, my water is perfectly clear and it run's clear during rapid rinse.

Could it be they didn't send me enough gravel? They send a sleeve which I think is 16 pounds, says it's good for 8 to 12 inch diameter tanks.

It isn't just the brown water at the hose bib.

When I backwash my carbon filter I can see just how much iron is getting by the Katalox Filter. A lot.

Is there anyone out there with a Katalox Filter who only sees clean water coming out of the filter?

So far I'm a non believer.