OldAtHeart

New Member

Hello -

I just found this forum after googling for hours and hours trying to learn more about my Fleck 9000 setup. Happily surprised to see a whole section dedicated to water softeners!

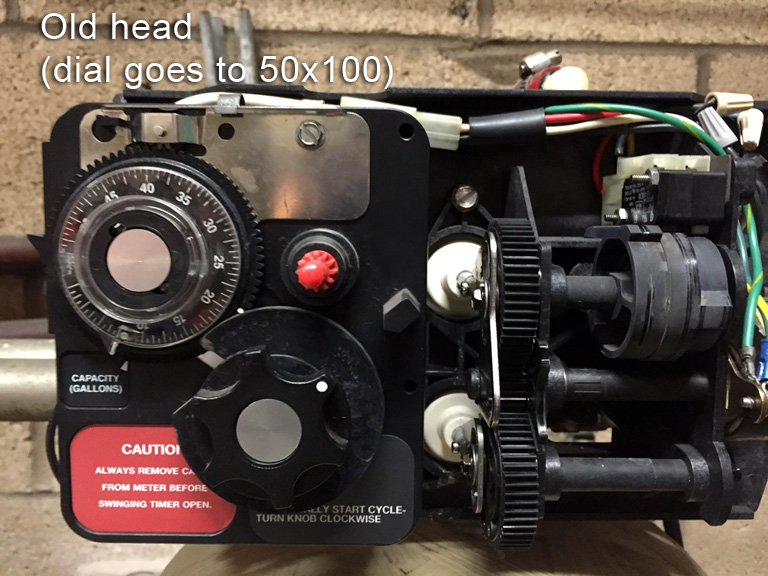

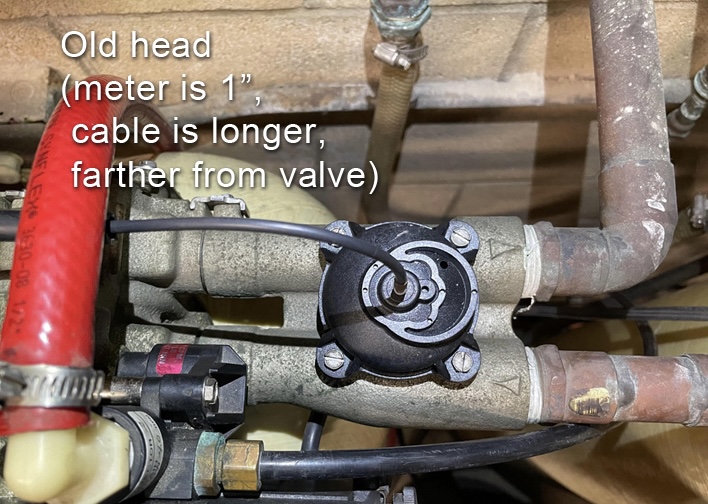

Here is my situation (bear with me if I say anything too dumb, I’m just starting to learn about this stuff): I have what I believe is an older Fleck 9000 with a 1” meter and an extended dial that goes up to ~50x100 gallons. The head is washed out and the parts are 20 years old so I want to replace the whole head (valve and meter?)

I ordered a Fleck 9000 online and once it arrived I realized it looked different than my existing one. I didn’t realize there were 3/4” versions and 1” versions and I bought what turns out to be a 3/4” version which has a lower range dial that goes to 20x100. Now that I see there is a difference I tried searching all over for a new 1” version but they are impossible to find.

So now I am trying to figure out what the best way to solve this is? Seems like my options are as follows:

1) Find an exact replacement for my Fleck 9000 1” with extended dial. Seems impossible.

2) Somehow use this new 9000 with 3/4” meter, but that will require a yoke or bypass to connect to my existing 1” supply line? And the dial doesn’t go up as high as my existing one so I might be forced to regenerate more often than needed?

3) Find a different head altogether - maybe Fleck 9100 which I read multiple posts on here about, but do they make that in a 1” version?

I will include photos of my old setup and this new 9000 3/4” head that I bought so you can see the differences. Appreciate any and all suggestions! Thanks!

I just found this forum after googling for hours and hours trying to learn more about my Fleck 9000 setup. Happily surprised to see a whole section dedicated to water softeners!

Here is my situation (bear with me if I say anything too dumb, I’m just starting to learn about this stuff): I have what I believe is an older Fleck 9000 with a 1” meter and an extended dial that goes up to ~50x100 gallons. The head is washed out and the parts are 20 years old so I want to replace the whole head (valve and meter?)

I ordered a Fleck 9000 online and once it arrived I realized it looked different than my existing one. I didn’t realize there were 3/4” versions and 1” versions and I bought what turns out to be a 3/4” version which has a lower range dial that goes to 20x100. Now that I see there is a difference I tried searching all over for a new 1” version but they are impossible to find.

So now I am trying to figure out what the best way to solve this is? Seems like my options are as follows:

1) Find an exact replacement for my Fleck 9000 1” with extended dial. Seems impossible.

2) Somehow use this new 9000 with 3/4” meter, but that will require a yoke or bypass to connect to my existing 1” supply line? And the dial doesn’t go up as high as my existing one so I might be forced to regenerate more often than needed?

3) Find a different head altogether - maybe Fleck 9100 which I read multiple posts on here about, but do they make that in a 1” version?

I will include photos of my old setup and this new 9000 3/4” head that I bought so you can see the differences. Appreciate any and all suggestions! Thanks!