Bobby Roberts

New Member

I'm not sure if this is something for a DIYer like myself, but I would love to try if possible. I have two issues with my bathroom sink plumbing.

One is that my water supply lines do not have shutoff valves, and I'm not sure how to add them because the supply itself is currently a male 3/8" thread. So the line from the faucet can screw directly into that, but I can't find a valve that fits that.

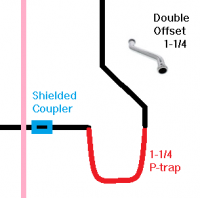

Second is that my drain line currently has a backwards flex line. The connection at the wall is a 1 1/4" female connection or nut, that is glued or otherwise held in place on the pipe itself. So currently the flex trap is screwed into that, but the other side of the flex line is just a smooth pipe that goes into the p trap, but nothing really holding it in place. I cannot seem to find anything to replace this with. Seems like a 1 1/4 PVC coupling would work but I can only find 1 1/2. Because the nut is there I can't just put a fernco on it, so if that's the solution I'm not sure how to get that nut off.

Any guidance would be greatly appreciated.

One is that my water supply lines do not have shutoff valves, and I'm not sure how to add them because the supply itself is currently a male 3/8" thread. So the line from the faucet can screw directly into that, but I can't find a valve that fits that.

Second is that my drain line currently has a backwards flex line. The connection at the wall is a 1 1/4" female connection or nut, that is glued or otherwise held in place on the pipe itself. So currently the flex trap is screwed into that, but the other side of the flex line is just a smooth pipe that goes into the p trap, but nothing really holding it in place. I cannot seem to find anything to replace this with. Seems like a 1 1/4 PVC coupling would work but I can only find 1 1/2. Because the nut is there I can't just put a fernco on it, so if that's the solution I'm not sure how to get that nut off.

Any guidance would be greatly appreciated.