Hi all,

Is a Grundfos 10S05-9 too big for my replacement pump?

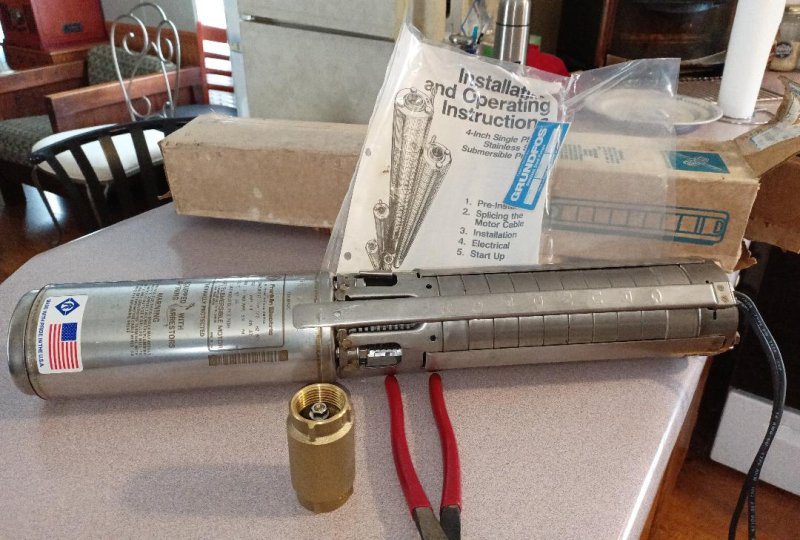

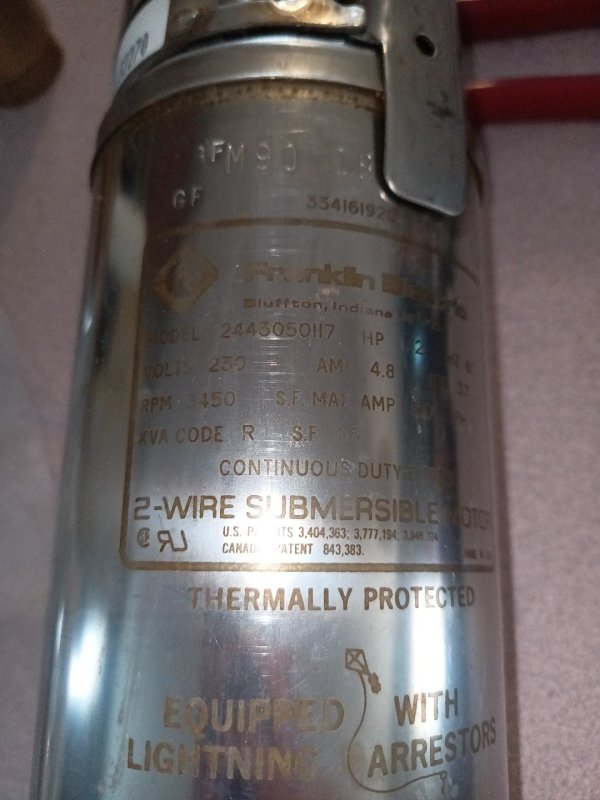

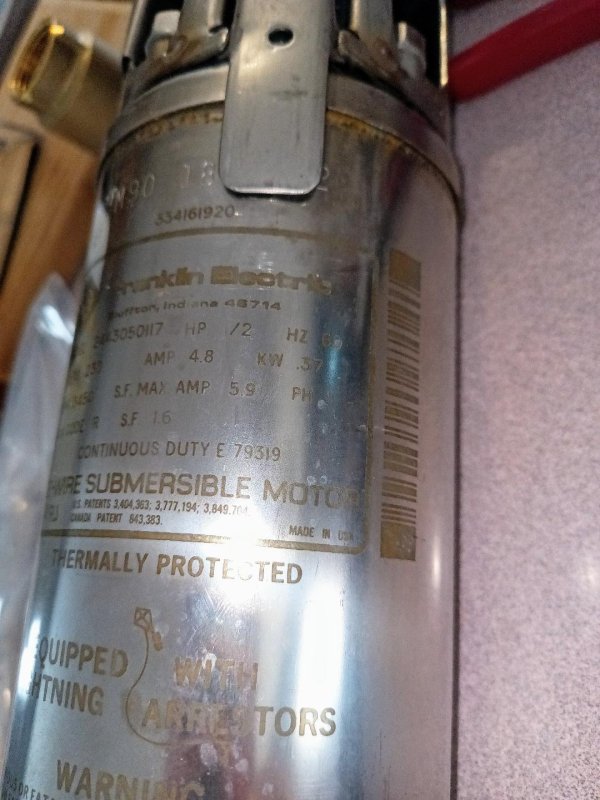

My son called me today and told me that one of the last independent hardware stores around here was going out of business. They had a brand new, unopened box, 1/2hp pump left and said that he would take $300 for it. I know that my current is a 1/2hp from the amp draw but that is all I know about it except who ever installed it did a poor job. I think that the home previous owner did it last.

Anyway after my son reading the specs on the new pump and being excited about the price, I told him to go a head and buy it.

Now that I am starting to do some more in-depth reading, I am not sure if this will work or not. So I am here where the pros are to ask!

Here are some pics of the tags and pump.

-

-

-

Also if it is the correct pump for my application, he threw in a 1" no lead brass check valve. Does anyone know if that pump has a built in check valve?

Maybe another question. I think my drop pipe is 3/4 ID. I am not sure how you measure the black poly pipe but poly pipe is clamped directly to a 3/4 fitting. would the existing drop pipe work with that new pump?

Thanks

Charrie

Is a Grundfos 10S05-9 too big for my replacement pump?

My son called me today and told me that one of the last independent hardware stores around here was going out of business. They had a brand new, unopened box, 1/2hp pump left and said that he would take $300 for it. I know that my current is a 1/2hp from the amp draw but that is all I know about it except who ever installed it did a poor job. I think that the home previous owner did it last.

Anyway after my son reading the specs on the new pump and being excited about the price, I told him to go a head and buy it.

Now that I am starting to do some more in-depth reading, I am not sure if this will work or not. So I am here where the pros are to ask!

Here are some pics of the tags and pump.

-

-

-

Also if it is the correct pump for my application, he threw in a 1" no lead brass check valve. Does anyone know if that pump has a built in check valve?

Maybe another question. I think my drop pipe is 3/4 ID. I am not sure how you measure the black poly pipe but poly pipe is clamped directly to a 3/4 fitting. would the existing drop pipe work with that new pump?

Thanks

Charrie