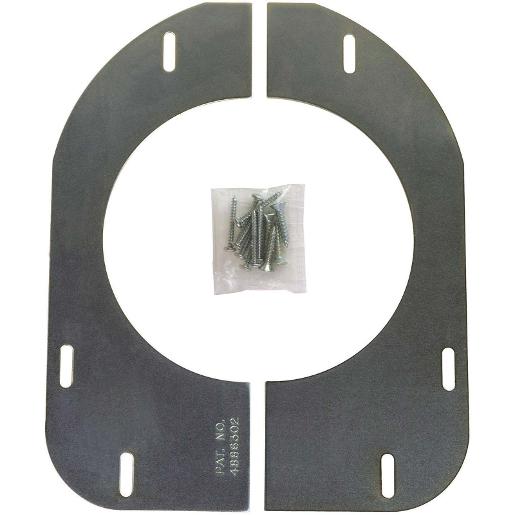

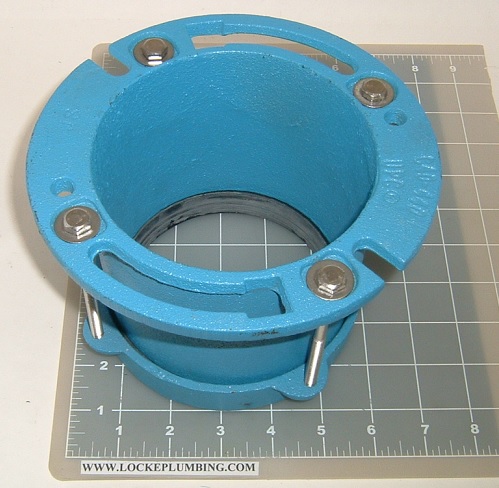

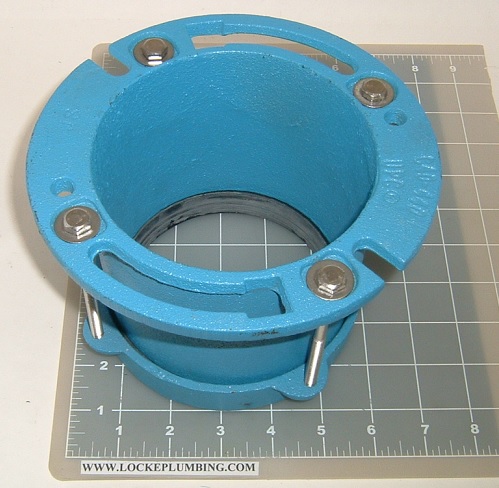

Another possiblity is a Jones Stephens or Plumbest C40440 outside compression flange. You would use a saw to clear the area. This expects the pipe to be 4 inches down, I think , but I don't know the precise dimensions needed. There are also versions for 2 inches down and 3 inches down, but those are not going deep enough. Is the 4 enough? That would be good too.

This would not work if the pipe was right up against a joist.

https://secure.lockeplumbing.com/detail.asp?c=Toilet Flanges&s=&s2=&sku=LOC-C40-440&r1=&r2=&r3=

A third choice would be to couple a plastic pipe to the cast iron. That would be done below, or you would rip up some flooring, and repair.

This would not work if the pipe was right up against a joist.

https://secure.lockeplumbing.com/detail.asp?c=Toilet Flanges&s=&s2=&sku=LOC-C40-440&r1=&r2=&r3=

A third choice would be to couple a plastic pipe to the cast iron. That would be done below, or you would rip up some flooring, and repair.

Last edited: