hbarkley

New Member

Hey everyone,

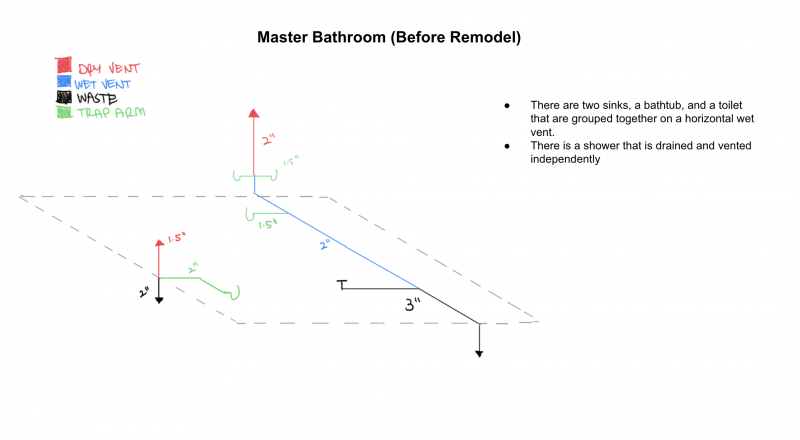

I'm at the plumbing stage of my DIY master bathroom remodel. I have some questions/concerns with how I've organized the layout for the fixtures. The information is in the pictures below. For reference, I live in North Carolina which I believe follows the IPC.

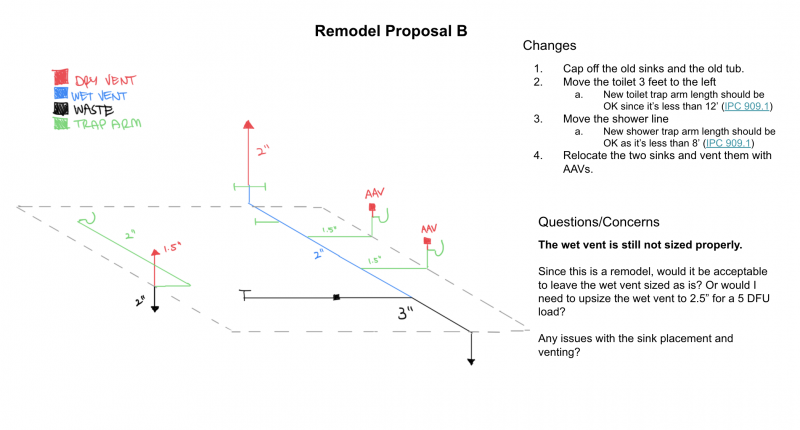

I'd prefer to go with Proposal A. But if I have to upsize the wet vent, then I've added another Proposal B to consider. I've added AAVs to vent the new sinks because that wall is load bearing and has some structural framing in the way of any potential roof vents.

Please let me know if either/both would work. Thanks!

I'm at the plumbing stage of my DIY master bathroom remodel. I have some questions/concerns with how I've organized the layout for the fixtures. The information is in the pictures below. For reference, I live in North Carolina which I believe follows the IPC.

I'd prefer to go with Proposal A. But if I have to upsize the wet vent, then I've added another Proposal B to consider. I've added AAVs to vent the new sinks because that wall is load bearing and has some structural framing in the way of any potential roof vents.

Please let me know if either/both would work. Thanks!

Last edited: