Killacam311

New Member

This is probably a very easy question but I just put down new subfloor and I don't want to screw anything up at this point.

I had to replace a rotten beam and new subfloor. I know an offset flange fits my current toilet so long as it is drilled as close to the beam as possible, because that is what was there before.

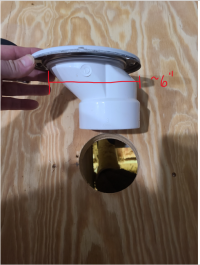

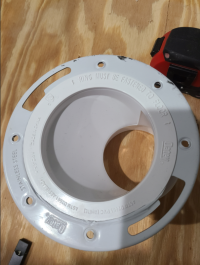

I can't find the answer to this question anywhere - was size diameter hole should I put in my new subfloor to fit this Oatey offset flange? PIctures included. I added a measurement of the flange, which is around 6 inches. I drill a 4 inch hole, which is my largest hole saw, but it doesn't fit.

I know I am overthinking this but I don't have anybody in my life to ask so if youtube doesn't have an example I rely on this community to give me piece of mind. Much appreciated. I want to draw a nice black circle on the subfloor and hit it once with the jigsaw.

I had to replace a rotten beam and new subfloor. I know an offset flange fits my current toilet so long as it is drilled as close to the beam as possible, because that is what was there before.

I can't find the answer to this question anywhere - was size diameter hole should I put in my new subfloor to fit this Oatey offset flange? PIctures included. I added a measurement of the flange, which is around 6 inches. I drill a 4 inch hole, which is my largest hole saw, but it doesn't fit.

I know I am overthinking this but I don't have anybody in my life to ask so if youtube doesn't have an example I rely on this community to give me piece of mind. Much appreciated. I want to draw a nice black circle on the subfloor and hit it once with the jigsaw.