KillSwitch

New Member

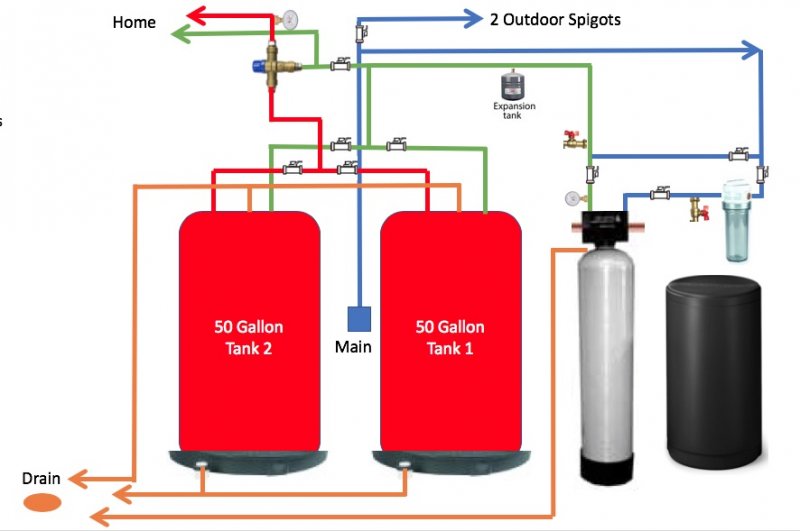

Welcome open and honest feedback from experts on my attached diagram to parallel two 50 gal electric tanks with thermostatic mixer, using 10 micron house filter and water softener.

I prefer the two 50 gal tank vs an 80 or 100. Both tanks will be set at 140 deg.

Welcome questions and feedback. Hope to improve on this setup the best I can before install.

I prefer the two 50 gal tank vs an 80 or 100. Both tanks will be set at 140 deg.

Welcome questions and feedback. Hope to improve on this setup the best I can before install.