K Bar

New Member

Hello,

This is my first time working on a well. Bought a little cabin in Lytle Creek, CA.

Old pump was not working. Well is 63 feet deep. Sandy creek bed DG type soil. I am literally in the wash.

I just put in a new 1/2 hp 230v pump at about 60' down (the drought has everything drying up and I had to go really close to the bottom just to get 7 or 8 feet below the water line. When I fired it up it ran for about ten seconds then shut off. After a minute or two it comes back on and runs for three or four seconds and shuts off. Seems like it would continue to do this if I left the power on. My best guess is that it is tripping the thermal overload protector. It sounds smooth and quiet--no funny cavitation noises or bubbles so I don't think it is sucking all the water out in those few seconds.

It delivered about two gallons in those first 10 or 15 seconds that it ran.

Looked to be a nice fat flow--this was done before connecting to pressure tank.

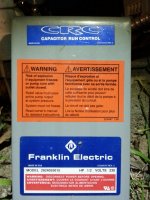

I did the basic volt meter tests (got exactly 240 volts at well head) and checked the motor winding numbers and wiring resistance. Everything seems to check out good.

The local well guys says I used to small of drop pipe--it's about 3/4 inch ID and the barbed fittings I had to use to connect the pump to the polypipe and well head pipe look to be about 3/8 inch ID--very small.

Could this restriction in really overload my pump that fast and shut it off.

How would this restriction be any different than what you would get if you used a Dole Valve.

Another potential culprit is the wiring coming out of my 220 breaker. Top half of the breaker has what looks like a 14 gauge wire and the bottom is 12 gauge--that can't be good but would that really cause this problem.

Any help much appreciated.

Kevin

This is my first time working on a well. Bought a little cabin in Lytle Creek, CA.

Old pump was not working. Well is 63 feet deep. Sandy creek bed DG type soil. I am literally in the wash.

I just put in a new 1/2 hp 230v pump at about 60' down (the drought has everything drying up and I had to go really close to the bottom just to get 7 or 8 feet below the water line. When I fired it up it ran for about ten seconds then shut off. After a minute or two it comes back on and runs for three or four seconds and shuts off. Seems like it would continue to do this if I left the power on. My best guess is that it is tripping the thermal overload protector. It sounds smooth and quiet--no funny cavitation noises or bubbles so I don't think it is sucking all the water out in those few seconds.

It delivered about two gallons in those first 10 or 15 seconds that it ran.

Looked to be a nice fat flow--this was done before connecting to pressure tank.

I did the basic volt meter tests (got exactly 240 volts at well head) and checked the motor winding numbers and wiring resistance. Everything seems to check out good.

The local well guys says I used to small of drop pipe--it's about 3/4 inch ID and the barbed fittings I had to use to connect the pump to the polypipe and well head pipe look to be about 3/8 inch ID--very small.

Could this restriction in really overload my pump that fast and shut it off.

How would this restriction be any different than what you would get if you used a Dole Valve.

Another potential culprit is the wiring coming out of my 220 breaker. Top half of the breaker has what looks like a 14 gauge wire and the bottom is 12 gauge--that can't be good but would that really cause this problem.

Any help much appreciated.

Kevin