Hi all,

I've been researching softeners and iron and manganese filters for a while now and I don't feel much further along than when I started. I see a lot about the Pro Ox filter but I have a couple of concerns the first being that there is a moving part inside the tank. Another is that it uses 100 gallons of water for backwashing. It's getting really tough to find any other systems that would work. My tests came up

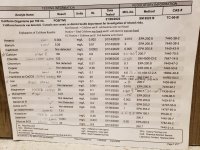

Iron 3.4

Manganese .07

Ph 7.51

Hardness as CaCO3 481

Does anyone have any recommendations of systems I could look at? Thanks so much for you help.

I've been researching softeners and iron and manganese filters for a while now and I don't feel much further along than when I started. I see a lot about the Pro Ox filter but I have a couple of concerns the first being that there is a moving part inside the tank. Another is that it uses 100 gallons of water for backwashing. It's getting really tough to find any other systems that would work. My tests came up

Iron 3.4

Manganese .07

Ph 7.51

Hardness as CaCO3 481

Does anyone have any recommendations of systems I could look at? Thanks so much for you help.