Greenleaf

New Member

In our recently purchased approx 20 yr old house, we have an in-floor radiant heating system, that seems to work quite poorly, as in very slow to heat (like, half a day to get rooms up to temp). I suspect the previous owners either did not use it, or only used it supplementally. (house also has gas fireplace & wood burning appliance). For some areas, at least, I think they simply ran the loops spaced too far apart to be very effective (between joist installation). In any case, on with the story...

After two months of this, the air bleed valve started to leak and drip water. I put a basin under it to catch drips and continued using the system. A couple of weeks later, I noticed a nasty sound coming from the circulation pump. I shut off the system for the day. The next day it seemed fine again, in fact, for a few days. But then the pump noise returned, and I noticed the temperature of the pump housing was too hot to hold my hand on it, but not sure if that is normal. Also during the period, the system seemed to be more noisy (air in the loops?). System has been shut-off since then.

I'm wondering if the bleeder valve was possibly bad enough to actually be causing air to be introduced into the system, eventually starving the pump itself of water, possibly now causing it to seize-up. Even if the pump was starved of water, perhaps a full flush after replacing the bleeder valve only, might get it back in order without needing to replace the pump cartridge.

Anyway, as of now I have ordered a replacement air bleed valve and pump cartridge, but would like some guidance on replacement sequence, as well as post-replacement air purge.

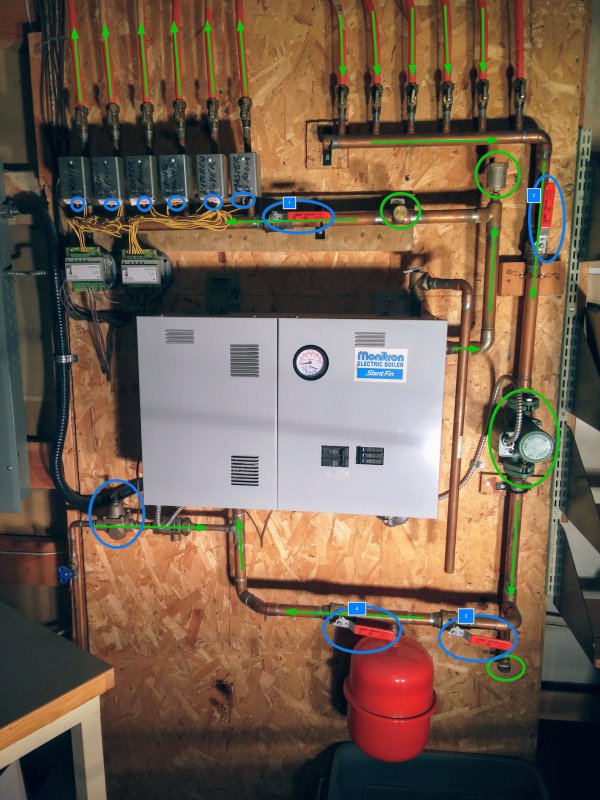

Here is a photo of the system, which I have tried to annotate as best I can (possibly incorrectly!). See notes below:

Here are my draft procedures to remediate these issues.

Circulation Pump cartridge replacement Sequence & Questions:

This one seems to be more straightforward since there are shut-offs immediate on either side of the pump:

This one I'm not so clear on which valves to shut-off as there is no shut-off between the boiler and the bleeder, but there is one on the other side of the bleeder. Perhaps shutting-off valve #1 above the boiler will be enough? Do I need to depressurize the system somehow? Perhaps I additionally need to shutoff the water from the main feed (far left blue valve below and to the left of the boiler (uncircled)).

Flush Procedure Sequence & Questions:

So as for flushing, here is my best guess as to procedure:

So, as you can see, most of my questions are around the air bleed valve replacement sequence, basically because I don't have a nice pair of shut-offs on either side of the valve.

If anyone is willing to chime-in with some guidance, tips, or warnings, it would be appreciated.

Cheers!

After two months of this, the air bleed valve started to leak and drip water. I put a basin under it to catch drips and continued using the system. A couple of weeks later, I noticed a nasty sound coming from the circulation pump. I shut off the system for the day. The next day it seemed fine again, in fact, for a few days. But then the pump noise returned, and I noticed the temperature of the pump housing was too hot to hold my hand on it, but not sure if that is normal. Also during the period, the system seemed to be more noisy (air in the loops?). System has been shut-off since then.

I'm wondering if the bleeder valve was possibly bad enough to actually be causing air to be introduced into the system, eventually starving the pump itself of water, possibly now causing it to seize-up. Even if the pump was starved of water, perhaps a full flush after replacing the bleeder valve only, might get it back in order without needing to replace the pump cartridge.

Anyway, as of now I have ordered a replacement air bleed valve and pump cartridge, but would like some guidance on replacement sequence, as well as post-replacement air purge.

Here is a photo of the system, which I have tried to annotate as best I can (possibly incorrectly!). See notes below:

Here are my draft procedures to remediate these issues.

Circulation Pump cartridge replacement Sequence & Questions:

This one seems to be more straightforward since there are shut-offs immediate on either side of the pump:

- shut off power to the system

- close shut-off valves 2 & 3 (at least) above & below the pump (if you can make out the labels)

- Replace cartridge

- Reopen valves

- Flush (see questions below on that)

This one I'm not so clear on which valves to shut-off as there is no shut-off between the boiler and the bleeder, but there is one on the other side of the bleeder. Perhaps shutting-off valve #1 above the boiler will be enough? Do I need to depressurize the system somehow? Perhaps I additionally need to shutoff the water from the main feed (far left blue valve below and to the left of the boiler (uncircled)).

Flush Procedure Sequence & Questions:

So as for flushing, here is my best guess as to procedure:

- Close valves 3 & 4 on either side of the pressure tank to stop water returning back to the boiler

- Attach a hose to the flush station on the bottom right (green circle) and open the valve there

- Manually override the flow valves into each loop (one at a time) using the switches on each loop valve (upper-left in small blue circles)

- If necessary, optionally open the pressure valve before the boiler (blue circle to the lower-left of the boiler) to increase the pressure as each loop is flushed (Is this always safe? Or should it only be special cases like 3rd floor loops, etc?)

- Return each loop valve back to auto mode

- Once all flushed, close the flush station and re-open the valves, etc.

So, as you can see, most of my questions are around the air bleed valve replacement sequence, basically because I don't have a nice pair of shut-offs on either side of the valve.

If anyone is willing to chime-in with some guidance, tips, or warnings, it would be appreciated.

Cheers!

Last edited: