Hi, I've searched & read various discussions with flow rates of various roughs, charts of PEX vs copper flows etc but not sure seen anyone specifically address pipe sizing differences in vs the outs.

Main feed in from my gravity spring fed system is 1" converting to 3/4" PEX & then tee appropriate sizing to individual fixtures (1/2 except for any tubs/showers, roman tub was planning use 3/4). I have delta 17T trims/cartridges which have higher flow. No stops in rough. Not sure how plays into it all but my basic gravity flow water pressure is about 27- 30. I might end up using a booster pump but that is situation at this time.

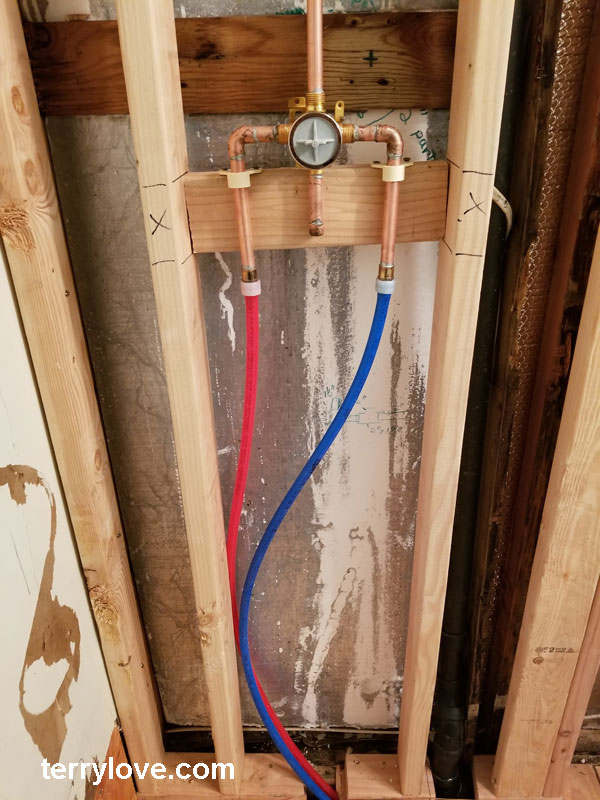

I have option using R10000UNBX or R10000PX. The px of course uses 1/2" PEX feeds which is so small & seems bottle neck ability flow obtained by trim. The shower & tub ports all support 1/2" copper so my thoughts were to use 3/4 PEX feeds which is closer but higher than the 1/2" copper size/flow. My stud bay (no option come in from either side of that bay) is 16oc so only about 14" work with. Once put the threaded adapter 1/2" fnpt to 3/4" PEX I can not get the 3/4" PEX with bend supports to fit inside the stud bay. So, seems like might be forced back to using the 1/2" PEX rough which just fits. So here are my questions.

With 1/2" PEX in how does that provide enough water flow to feed what is 1/2" copper size (thinking 3/4" PEX possible for riser & drop with appropriate drop ear elbows attach spout & shower head). Flow volume in so much less than what piping allows going up/down. The rough & cartridge also allow for much higher flow than the 1/2" PEX provides. I can handle lower flow to shower but don't want take long time fill high volume tub

Thinking out of the box a bit. Are there elbows that could screw onto the rough in 1/2" FIP to 3/4" PEX? I haven't found such except drop ears which I have on hand. So other questions? Would such an elbow 90 be to restrictive right next to the valve? If not, can ears be ground down enabling to use as a elbow? I have drop ears that fit but the ears won't allow proper placement.

Due to joist directly under the stud bay I will be bringing water up through floor under tub & shifting it into the wall cavity. If use copper supply in would have additional elbows further restrictions/complications in routing.

Might have just come up with a viable solution... Guess could come out with a 3/4" PEX adapter which I have, stub of 3/4 & add a 90 elbow PEX to PEX to drop it down. Was hoping avoid adding more joints inside cavity though. Fortunately, do have full length access panel to everything from back plus this over unfinished basement & clamp ring tools fit tighter locations should a fix be necessary.

There probably more options but right now (for my abilities & unavailability plumbers) it seems using modified drop ear elbow or adapter to PEX stub & elbow my best choices. Plus benefit of easier fixes should leaks develop especially if I sweat copper.

Thanks in advance for any thoughts, additional options that I'm missing. Maybe 3/4 not going to add any benefit overall but it seems logical to me based on calculations. However, theory often not same as real life.

Main feed in from my gravity spring fed system is 1" converting to 3/4" PEX & then tee appropriate sizing to individual fixtures (1/2 except for any tubs/showers, roman tub was planning use 3/4). I have delta 17T trims/cartridges which have higher flow. No stops in rough. Not sure how plays into it all but my basic gravity flow water pressure is about 27- 30. I might end up using a booster pump but that is situation at this time.

I have option using R10000UNBX or R10000PX. The px of course uses 1/2" PEX feeds which is so small & seems bottle neck ability flow obtained by trim. The shower & tub ports all support 1/2" copper so my thoughts were to use 3/4 PEX feeds which is closer but higher than the 1/2" copper size/flow. My stud bay (no option come in from either side of that bay) is 16oc so only about 14" work with. Once put the threaded adapter 1/2" fnpt to 3/4" PEX I can not get the 3/4" PEX with bend supports to fit inside the stud bay. So, seems like might be forced back to using the 1/2" PEX rough which just fits. So here are my questions.

With 1/2" PEX in how does that provide enough water flow to feed what is 1/2" copper size (thinking 3/4" PEX possible for riser & drop with appropriate drop ear elbows attach spout & shower head). Flow volume in so much less than what piping allows going up/down. The rough & cartridge also allow for much higher flow than the 1/2" PEX provides. I can handle lower flow to shower but don't want take long time fill high volume tub

Thinking out of the box a bit. Are there elbows that could screw onto the rough in 1/2" FIP to 3/4" PEX? I haven't found such except drop ears which I have on hand. So other questions? Would such an elbow 90 be to restrictive right next to the valve? If not, can ears be ground down enabling to use as a elbow? I have drop ears that fit but the ears won't allow proper placement.

Due to joist directly under the stud bay I will be bringing water up through floor under tub & shifting it into the wall cavity. If use copper supply in would have additional elbows further restrictions/complications in routing.

Might have just come up with a viable solution... Guess could come out with a 3/4" PEX adapter which I have, stub of 3/4 & add a 90 elbow PEX to PEX to drop it down. Was hoping avoid adding more joints inside cavity though. Fortunately, do have full length access panel to everything from back plus this over unfinished basement & clamp ring tools fit tighter locations should a fix be necessary.

There probably more options but right now (for my abilities & unavailability plumbers) it seems using modified drop ear elbow or adapter to PEX stub & elbow my best choices. Plus benefit of easier fixes should leaks develop especially if I sweat copper.

Thanks in advance for any thoughts, additional options that I'm missing. Maybe 3/4 not going to add any benefit overall but it seems logical to me based on calculations. However, theory often not same as real life.