Lithnights

Member

I have PEX throughout my home, all fixtures with homeruns. Most are 3/8", bathtubs and outside spigots are 1/2". Pressure has always been fine.

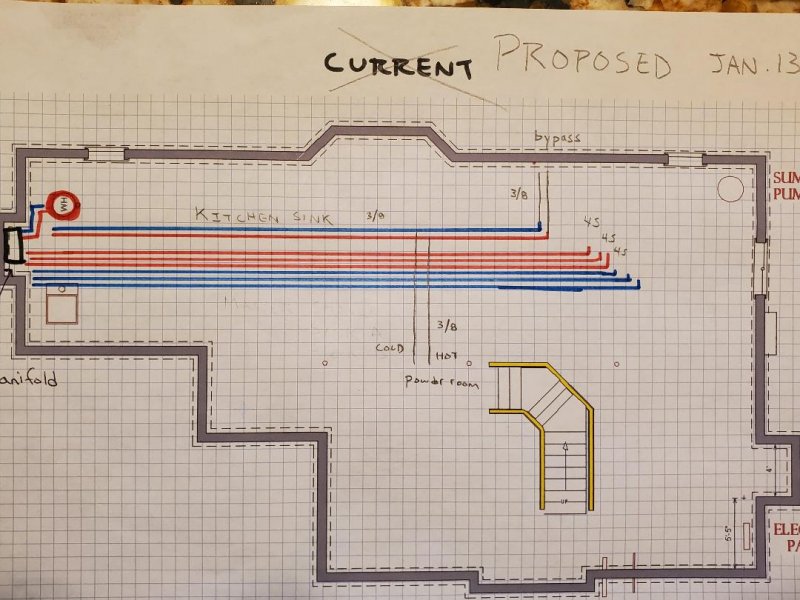

I had a recirculating pump installed and want to use it for my kitchen sink and powder room sink (about 20 feet away from kitchen). All PEX is accessible in basement.

I want to keep the existing 3/8" PEX to the kitchen sink and tee in the existing 3/8" PEX that feeds the powder room sink. i.e. one 3/8" from manifold, to feed 2 sinks. This will allow me to use the reciurculator more efficiently since the powder room sink will be able to use some of the hot water in the kitchen sink pipe... i.e. it will only have to flush out a small amount of cold water before the hot water gets there. SEE ATTACHED PICTURE.

It will be rare that the kitchen sink and powder room sink are used at the same time, and if they are, we're OK with a temporary drop in pressure. We feel the cost savings of keeping the 3/8" instead of switching to 1/2" would be worth it. We have pricey propane so don't want to have to heat twice as much volume, using 1/2". Also, the existing powder room sink only has a 1 gallon per minute flow to it anyway.. which we're totally fine with. Not sure if that's typical or not..

Thoughts?

Thanks in advance!

I had a recirculating pump installed and want to use it for my kitchen sink and powder room sink (about 20 feet away from kitchen). All PEX is accessible in basement.

I want to keep the existing 3/8" PEX to the kitchen sink and tee in the existing 3/8" PEX that feeds the powder room sink. i.e. one 3/8" from manifold, to feed 2 sinks. This will allow me to use the reciurculator more efficiently since the powder room sink will be able to use some of the hot water in the kitchen sink pipe... i.e. it will only have to flush out a small amount of cold water before the hot water gets there. SEE ATTACHED PICTURE.

It will be rare that the kitchen sink and powder room sink are used at the same time, and if they are, we're OK with a temporary drop in pressure. We feel the cost savings of keeping the 3/8" instead of switching to 1/2" would be worth it. We have pricey propane so don't want to have to heat twice as much volume, using 1/2". Also, the existing powder room sink only has a 1 gallon per minute flow to it anyway.. which we're totally fine with. Not sure if that's typical or not..

Thoughts?

Thanks in advance!

Last edited: