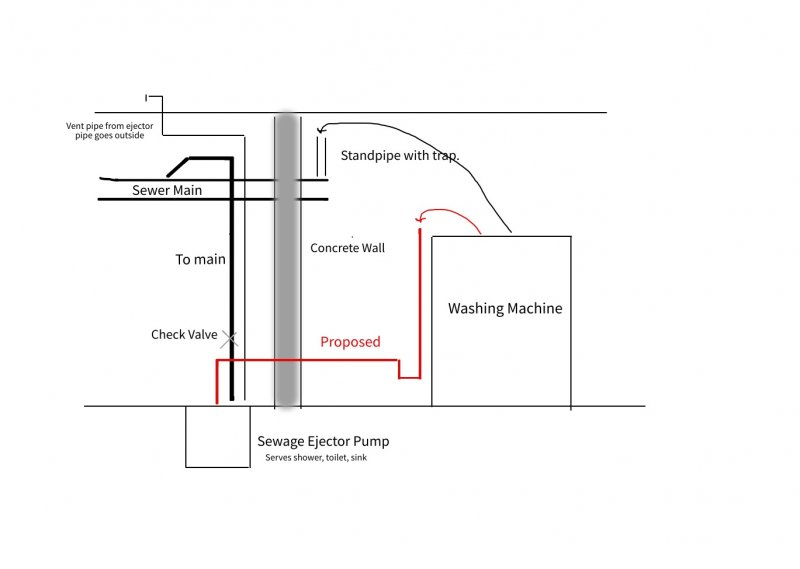

Hi, always enjoy browsing this forum and have a question I could use help on. In short, in our basement, the washing machine (previously a front load) drained up and unit a stand pipe with trap that went into the septic line within the basement - about 5.5 feet above the floor. Because of the height, the standpipe is nearly up into the rafters in the basement (prob 7 feet height overall). To get the drain to that stand pipe, they added an extra piece of rubber hose. I'm concerned that it is pumping too high and / or hose is too long.

At the same time, on the other side of this room there is a finished bathroom area where the shower, toilet and sink is handled by a sewage ejector pit / pump. That pump drains up and into the septic line - same line as the washing machine now - just a different location along the line. They added a vent to the ejector pipe but it only goes outside and under an exterior overhang mudroom, etc (this is a 100+ year old house). I recently changed out the ejector pump and added a new check value and ball valve.

We are replacing the washing machine and i'm at a point where i'd like to make sure I'm changing things for the better. I have never liked the idea of the washing machine pumping up to that stand pipe. Also, I realize it should be 2" versus the current 1.5". Seems given i have the ejector pump, i should build out a generally correct washing machine drain, core through the poured concrete wall (would prob do 3" hole through wall), and run the drain to the ejector pump. I would then cap off that current stand pipe.

I know there are probably other details i'm leaving out. I'm just curious to see of those with experience in this area would say that makes sense to go this route. The ejector pump is a Zoeller 0.5 hp pump - i think just over 100 gpm. Washing machine instructions note having a drain with a capacity of 17 gpm. I realized I'd have to consider a scenario where the shower and toilet is operating at the same time - although it is a spare bathroom not often used. Would appreciate any obvious points I should consider. I added a rough sketch that i hope conveys the scenario.

Thank you.

At the same time, on the other side of this room there is a finished bathroom area where the shower, toilet and sink is handled by a sewage ejector pit / pump. That pump drains up and into the septic line - same line as the washing machine now - just a different location along the line. They added a vent to the ejector pipe but it only goes outside and under an exterior overhang mudroom, etc (this is a 100+ year old house). I recently changed out the ejector pump and added a new check value and ball valve.

We are replacing the washing machine and i'm at a point where i'd like to make sure I'm changing things for the better. I have never liked the idea of the washing machine pumping up to that stand pipe. Also, I realize it should be 2" versus the current 1.5". Seems given i have the ejector pump, i should build out a generally correct washing machine drain, core through the poured concrete wall (would prob do 3" hole through wall), and run the drain to the ejector pump. I would then cap off that current stand pipe.

I know there are probably other details i'm leaving out. I'm just curious to see of those with experience in this area would say that makes sense to go this route. The ejector pump is a Zoeller 0.5 hp pump - i think just over 100 gpm. Washing machine instructions note having a drain with a capacity of 17 gpm. I realized I'd have to consider a scenario where the shower and toilet is operating at the same time - although it is a spare bathroom not often used. Would appreciate any obvious points I should consider. I added a rough sketch that i hope conveys the scenario.

Thank you.