GForman

New Member

We built our house about 2 1/2 years ago. We are out in the country so we had a well installed. On the well tag it states the well is 80ft deep with casing depth at 60ft and static water level at 45ft and the well yields 15gpm. I'm not sure what model pump we have but I'm sure I can contact my builder to get in touch with the driller to get that info. We have started the process of installing some irrigation since we have almost 1/2 of an acre that we want to plant grass seed and irrigate.

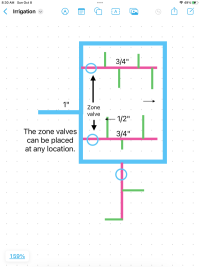

My pressure tank is an Amtrol CH4202 set at 45/65. I installed a tee after the pressure tank that will run to my timer and valves. I ran 3/4" poly pipe 150ft from the tee to a ball valve, check valve and filter before entering my valve manifold. Zone 1 is 193ft from the valves, Zone 2 is 247ft and Zone 3 is 200ft. Each zone was run using 3/4" poly pipe. Each zone has 7 heads on it. When testing I ran about 275ft of 3/4" poly pipe with 7 rotor heads on it and found that set up allowed me to run the sprinklers without the pump cycling on and off. Since I've installed my heads my zones are not performing as well as I'd hoped. I'm assuming I didn't calculate enough for friction loss or loss of flow rate through elbows and fittings. Zone 1 provided decent enough coverage, Zone 2 didn't seem to have enough pressure to pop up all the heads fully. Zone 3 will be finished installing tomorrow so, I will do a test run on it. When testing Zone 1 and 2, I found that my well pump was cycling on and off. I can install different nozzles to compensate some but wondering what my best plan of action would be...

My pressure tank is an Amtrol CH4202 set at 45/65. I installed a tee after the pressure tank that will run to my timer and valves. I ran 3/4" poly pipe 150ft from the tee to a ball valve, check valve and filter before entering my valve manifold. Zone 1 is 193ft from the valves, Zone 2 is 247ft and Zone 3 is 200ft. Each zone was run using 3/4" poly pipe. Each zone has 7 heads on it. When testing I ran about 275ft of 3/4" poly pipe with 7 rotor heads on it and found that set up allowed me to run the sprinklers without the pump cycling on and off. Since I've installed my heads my zones are not performing as well as I'd hoped. I'm assuming I didn't calculate enough for friction loss or loss of flow rate through elbows and fittings. Zone 1 provided decent enough coverage, Zone 2 didn't seem to have enough pressure to pop up all the heads fully. Zone 3 will be finished installing tomorrow so, I will do a test run on it. When testing Zone 1 and 2, I found that my well pump was cycling on and off. I can install different nozzles to compensate some but wondering what my best plan of action would be...