The

Ultra-Fin installation brochure indicates that it puts out about 7 BTU/hr per square foot into a 70F room at a water temp of 100F, and about 27 BTU/hr per square foot at a water temp of 150F, which is a LOT!

It's important to get a better handle on the actual zone by zone load numbers and the square footage of the radiant floor supplying that heat to get a good estimate of what the water temperatures need to be. As I indicated in response #14, the 44K heat load @ 32F is simply

not a credible number, and if the curves were set up using that load calculation the water temperatures can be lower, and I suspect it's MUCH lower (which is why you never need 180F water, since you never need 44K of output out of the radiation.)

In the absence of better load numbers it's still possible to find out what water temperatures are

actually needed empirically, by lowering the water temperatures to the point where the zone thermostats are almost never being satisfied, but the room temps aren't actually losing ground.

On p16 of the boiler manual they state:

Where outdoor reset is applied without the indoor sensor feedback option, some manual adjustment may be required to achieve the desired comfort level.

Do you have the indoor sensor option?

I assume you have the outdoor sensor installed, so that the boiler actually knows the outdoor temp?

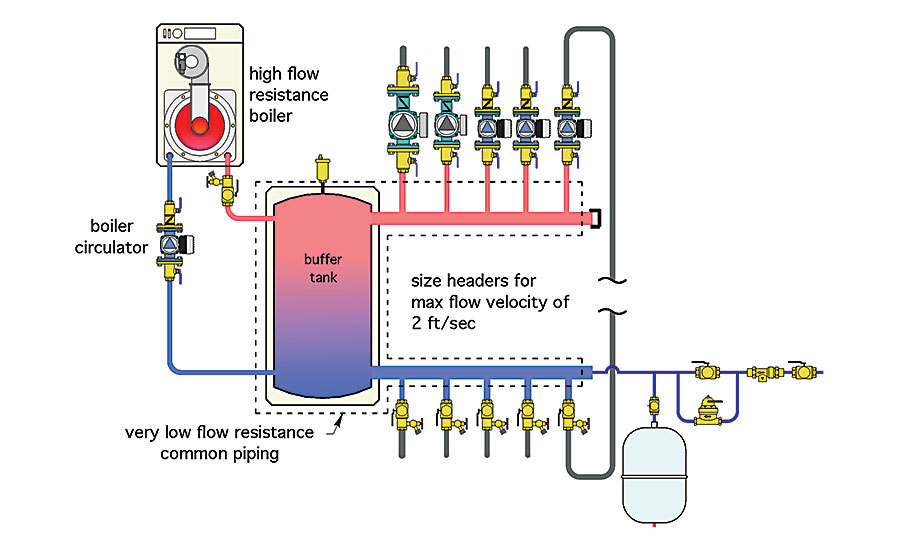

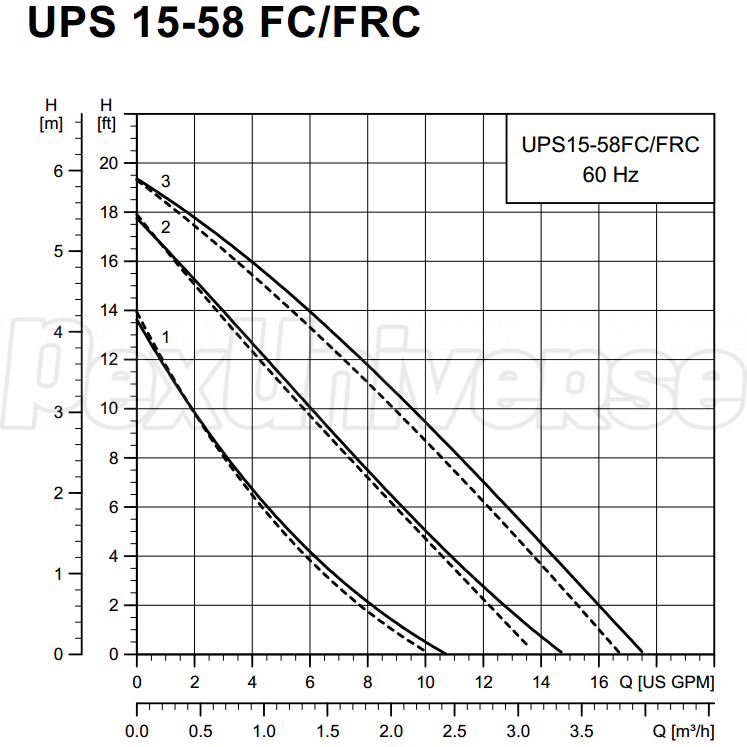

With the thermal mass of a buffer tank in the system you probably don't have to be concerned about setting temperature minimums to avoid short-cycling issues, but with fin-tube baseboard in some zones you probably want to set the minimum at about 110-115F, since the output of fin-tube below that temperature is very non-linear (but the Ultra-Fin should still do fine at very low water temps.)

I suspect your whole-house load is about 30-35K @ +25F, about 3/4 of the 44K that the radiation emits at 180F (per your sheet.) If that WAG is correct, all else being equal (no under or over-radiated zones) you should be able to heat the house to 70F indoors with ~155F water when it's 25F outside (which delivers ~30 BTU/hr per square foot out of the radiant, ~400 BTU/hr per running foot out of the fin tube), and the reset curve would drop the supply temp to 115F when it's 55F or so outside. But for tighter, better insulated houses it could easily be as low as 140F @ 25F outside and still work.

Looking your screen shot of programming options, leave the 115F minimum temp alone for now (110F would probably be OK too) but set the Design Supply Temperature to 155F, see it it still keeps up overnight. If it does, drop Design Supply Temperature to 145F and see if it keeps up overnight. If it does, cut it another 5F to 140F @ +25F outdoors.

Keep going 5F at a time on successive days until you find the water temperature at which one or more zones lose ground overnight, always below the thermostat's setpoint. When that Design Supply Temperature temperature is found, raise it back up 5F for a day to verify that it still keeps up, then start backing off just degree at a time. With a week's worth of cool weather you can probably get it dialed pretty closely, but may still need to tweak it up again a degree at a time if it starts losing ground at outdoor temps below 30F (or below 25F.)

In IBC's terminology the "supply differential" is the range of temperature swing around the target temperature that the boiler allows before firing or re-starting the boiler. eg, when the curve's target temp is 133F and the differential is set to 20F it will turn off the burner when when the system temp rises to where it hits 143F even at minimum fire, and won't refire until it drops to 123F. As long as it's not short-cycling (probably won't with a buffer that size) setting it to 10F would probably keep it in the condensing zone more of the time. (TBD.)

Time the actual burns, not just the calls for heat from the thermostats. With a boiler like this burns as short as 3 minutes are just fine, as long as the burns per hour aren't more than 5. I suspect the thermal mass of the buffer is enough to ensure burns longer than that that no matter how little heat is being emitted by the zone radiation, even with a 10F Supply Differential.