Another valuable wealth of knowledge here from Dana.

I just lowered the Design Supply to 155F and supply differential to 10F. I never know what supply differential is. I always thought this is what I want the swt/rwt difference to be set at. I will keep an eye on that to see whether the tighter differential will short-cycle the boiler. It hasn't at 20F. Just slightly at the end of the cycle for the one smallest zone. Burner just stopped and let the pumps circulate until the thermostat satisfied on that zone.

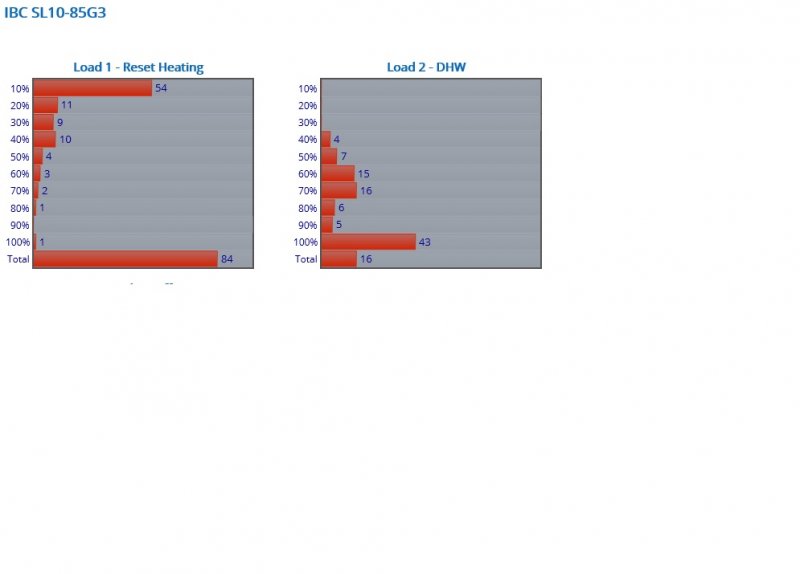

Our boiler now comes on and stays on fairly long at low output heating range most of the time as shown here.

I say, this winter so far, the number of cycle per day is 10 or so according to the boiler statistics counter.

I just lowered the Design Supply to 155F and supply differential to 10F. I never know what supply differential is. I always thought this is what I want the swt/rwt difference to be set at. I will keep an eye on that to see whether the tighter differential will short-cycle the boiler. It hasn't at 20F. Just slightly at the end of the cycle for the one smallest zone. Burner just stopped and let the pumps circulate until the thermostat satisfied on that zone.

Our boiler now comes on and stays on fairly long at low output heating range most of the time as shown here.

I say, this winter so far, the number of cycle per day is 10 or so according to the boiler statistics counter.