Davie

Member

A few years ago, I got some great help here doing heat loss calculations, choosing a boiler, and designing a radiant system for my home. The system is installed now, and it ran well all last winter. I'm very happy with how efficient it has been, and how comfortable it is. Thanks to everyone who helped me, but especially to @Dana, whose many comments were invaluable.

I'm now interested in fine-tuning the system to see if I can get it to run a bit more smoothly.

I am running an IBC boiler, the SL 10-85 G3 on outdoor reset mode, with a primary/secondary loop, and 3 zones controlled by zone valves. All three zones have cast iron rads, and two of them also have radiant floors. I have a grundfos alpha2 on the primary, running on speed "I", and a taco VT2218 on the secondary loop, running on delta-t mode, with the temp-diff set to 9 degrees celsius (16F).

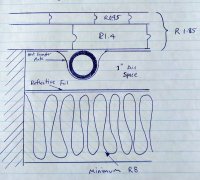

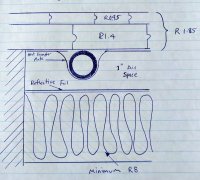

Here's a look at the primary/secondary piping:

And here I've drawn over it to make it a bit clearer:

I've noticed that the primary loop always remains hotter than the secondary. On warmer days, this can result in the boiler shutting off while the system continues to circulate, and then firing back on when the system temperature has dropped sufficiently. (This particular circumstance seems particularly prone to happening when only Zone 2 is calling for heat.)

Today, for example, the temperature outdoors was 10 celsius and only Zone 2 was calling for hear. The "target" boiler temp was 34C, based on the reset parameters, but actual supply temp rose to 39C (primary loop), while the temperature in the secondary loop was only 34C.

I think this is because my primary (boiler) loop has a higher flow rate than my secondary (zone) loop. So, some of the hot water from the boiler is bypassing the closely spaced tees, and heading back to the return side of the boiler.

I know that it's impractical to expect to have identical flow rates through the two pumps, but it seems to me that if one pump has to run more flow than the other, the more efficient option would be to have higher flow through the secondary loop. My thought is that this would help prevent the primary loop from overheating when demand is low (ie when outdoor temperatures are quite a bit above freezing) by sucking all the newly heated water into the zones, and ensuring only the coolest water in the system is heading back to the boiler return.

So my question is about how to set my pumps.

The lowest flow rate I seem to be able to get from the Grundfos Alpha2 is about 3.5 GPM (the display switches back and forth between 3 & 4). I don't believe there is any change in head in the primary loop as zones open and close on the secondary, so I think that flow rate is pretty constant. The flow through the Taco VT2218 varies based on which zones are open. It seems to be something like this:

Zone 1 ...........2 GPM

Zone 2 ...........1 GPM

Zone 1 & 2 .....3 GPM

Zone 0 & 1 .....4 GPM

All zones ........5 GPM

So, in three of these 5 cases, the flow rate through the boiler is higher than through the zones.

It's too late now for me to buy different pumps, so I'm going to work with what I have.

I'm experimenting with Constant Speed mode on the Taco, but preliminary testing seems to show that the Delta-T mode was operating as though it was in Speed 1. I never actually get the 15F temperature drop that I designed the system to operate with -- it's usually more like 9F (measured on the secondary loop). So, I think the pump is probably just trying to run as slowly as it can to increase the delta-t.

I'm now trying it out on Speed 2, and while I like the higher flow rate in the secondary loop, I imagine the temperature drop will reduce.

Should I be trying something else here? Am I looking at this in the right way? I am thinking I could try swapping the pumps, one for the other, and see what that does to the flow rates. The boiler manufacturer states minimum flow rate at 2GPM, so I could theoritically cut back by 40% or so, but I'd rather not go to the trouble of all that before hearing from you folks.

Any thoughts or suggestions would be much appreciated. Thanks!

I'm now interested in fine-tuning the system to see if I can get it to run a bit more smoothly.

I am running an IBC boiler, the SL 10-85 G3 on outdoor reset mode, with a primary/secondary loop, and 3 zones controlled by zone valves. All three zones have cast iron rads, and two of them also have radiant floors. I have a grundfos alpha2 on the primary, running on speed "I", and a taco VT2218 on the secondary loop, running on delta-t mode, with the temp-diff set to 9 degrees celsius (16F).

Here's a look at the primary/secondary piping:

And here I've drawn over it to make it a bit clearer:

I've noticed that the primary loop always remains hotter than the secondary. On warmer days, this can result in the boiler shutting off while the system continues to circulate, and then firing back on when the system temperature has dropped sufficiently. (This particular circumstance seems particularly prone to happening when only Zone 2 is calling for heat.)

Today, for example, the temperature outdoors was 10 celsius and only Zone 2 was calling for hear. The "target" boiler temp was 34C, based on the reset parameters, but actual supply temp rose to 39C (primary loop), while the temperature in the secondary loop was only 34C.

I think this is because my primary (boiler) loop has a higher flow rate than my secondary (zone) loop. So, some of the hot water from the boiler is bypassing the closely spaced tees, and heading back to the return side of the boiler.

I know that it's impractical to expect to have identical flow rates through the two pumps, but it seems to me that if one pump has to run more flow than the other, the more efficient option would be to have higher flow through the secondary loop. My thought is that this would help prevent the primary loop from overheating when demand is low (ie when outdoor temperatures are quite a bit above freezing) by sucking all the newly heated water into the zones, and ensuring only the coolest water in the system is heading back to the boiler return.

So my question is about how to set my pumps.

The lowest flow rate I seem to be able to get from the Grundfos Alpha2 is about 3.5 GPM (the display switches back and forth between 3 & 4). I don't believe there is any change in head in the primary loop as zones open and close on the secondary, so I think that flow rate is pretty constant. The flow through the Taco VT2218 varies based on which zones are open. It seems to be something like this:

Zone 1 ...........2 GPM

Zone 2 ...........1 GPM

Zone 1 & 2 .....3 GPM

Zone 0 & 1 .....4 GPM

All zones ........5 GPM

So, in three of these 5 cases, the flow rate through the boiler is higher than through the zones.

It's too late now for me to buy different pumps, so I'm going to work with what I have.

I'm experimenting with Constant Speed mode on the Taco, but preliminary testing seems to show that the Delta-T mode was operating as though it was in Speed 1. I never actually get the 15F temperature drop that I designed the system to operate with -- it's usually more like 9F (measured on the secondary loop). So, I think the pump is probably just trying to run as slowly as it can to increase the delta-t.

I'm now trying it out on Speed 2, and while I like the higher flow rate in the secondary loop, I imagine the temperature drop will reduce.

Should I be trying something else here? Am I looking at this in the right way? I am thinking I could try swapping the pumps, one for the other, and see what that does to the flow rates. The boiler manufacturer states minimum flow rate at 2GPM, so I could theoritically cut back by 40% or so, but I'd rather not go to the trouble of all that before hearing from you folks.

Any thoughts or suggestions would be much appreciated. Thanks!