If your well makes 15 GPM, there really is no reason for the cistern tank and extra booster pump. I see a lot of pump guys set systems up with cisterns and booster pumps to try and keep the well pump from being cycled to death. Simply using the Cycle Stop Valve on the well pump solves this problem and eliminates the need for a cistern and booster pump. See what others have said about it after doing the same thing you are doing here.https://cyclestopvalves.com/pages/reviews

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can Pressure tanks be installed above a jet pump?

- Thread starter 6.7L_MegaCab

- Start date

-

- Tags

- jet pump pressure tanks

Users who are viewing this thread

Total: 3 (members: 0, guests: 3)

6.7L_MegaCab

New Member

I'm sold! I'll return the other pressure tanks to HD. Looking at the picture I posted, what CSV system do I need? The pump has the pressure switch integrated into a line coming off the side of the pump. While I understand I can isolate the tank, that is going to have to be something for the future because of the way the lines are connected and ran (seems like all over the place). I'll have to do a lot of digging to figure out where the line for the new well is running. I know where the line is at going to the house. Once I finish the backyard and deck, I'll have the time to look into digging up the line from the well.

I'll look into finding a bottom float switch as well and use that to stop the pump in the rare chance the cistern runs low and relocate the pump saver to the well pump.

@valveman thank you very much for the info. I've been reading the stuff on your website and am quite intrigued by the CSV.

Which system do I need for the current setup?

I'll look into finding a bottom float switch as well and use that to stop the pump in the rare chance the cistern runs low and relocate the pump saver to the well pump.

@valveman thank you very much for the info. I've been reading the stuff on your website and am quite intrigued by the CSV.

Which system do I need for the current setup?

Sponsor

Paid Advertisement

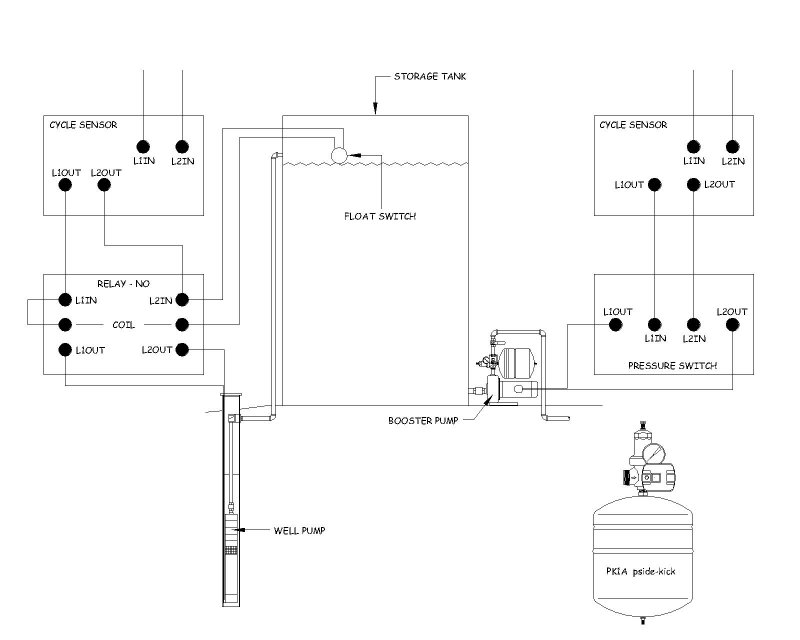

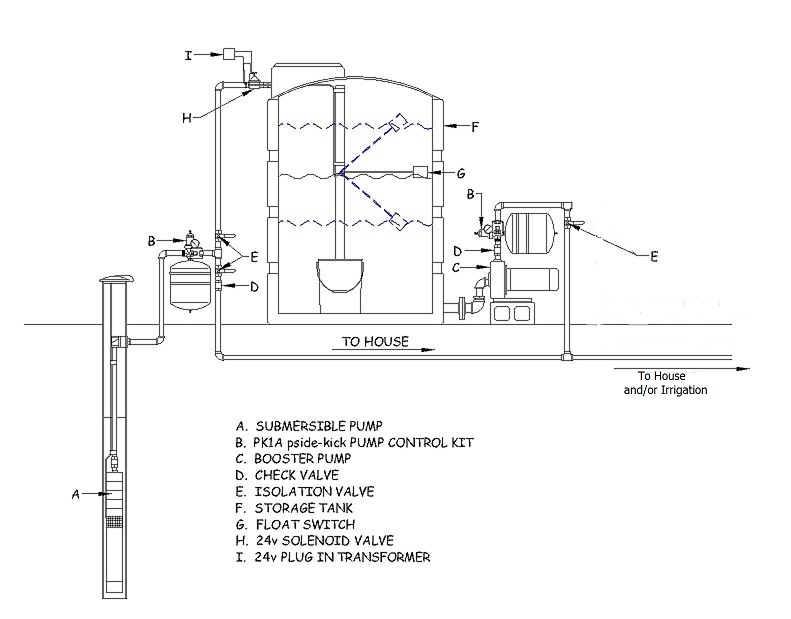

The PK1A kit has everything you need for either the well pump, booster pump, or both. The PK1A kit comes with a pressure switch and a diagram for how to wire around the switch mounted on the side of the motor. You don't have to remove the existing switch, just wire around it as shown in the wiring diagram for "jet pumps".

Depending on which "pump saver" you have, it may or may not work with the pump using the CSV. The CSV makes the amps drop almost as much as when the well runs dry, and some "pump savers" won't set low enough to work properly. You might want to consider a Cycle Sensor instead, which is just our brand of "pump saver", made to work with or without a CSV system. You can use one on the well pump and another on the cistern pump as well, which will keep you from having to install a safety float switch at the bottom of the cistern tank.

Depending on which "pump saver" you have, it may or may not work with the pump using the CSV. The CSV makes the amps drop almost as much as when the well runs dry, and some "pump savers" won't set low enough to work properly. You might want to consider a Cycle Sensor instead, which is just our brand of "pump saver", made to work with or without a CSV system. You can use one on the well pump and another on the cistern pump as well, which will keep you from having to install a safety float switch at the bottom of the cistern tank.

6.7L_MegaCab

New Member

@valveman, Thank you very much for the info! It is the LittleFuse PumpSaver 233P-1.5, which looks like it can be calibrated to detect dry-run or dead-head (currently disconnected--see below). Your diagrams are quite interesting. I kind of wonder why they didn't tie in the submersible pump to feed to the house and the cistern. I'm learning way more about this well-water system than I came here for. That is a great thing!

I am looking at the kit and see the larger the tank, the less the average daily run cycles. Looking at some of the reviews, it seems most folks went with the 4.4 instead of the 10-gallon tank. I also see a few larger tanks used with this system - so the CSV is independent of tank size? Any issues running a 10-gallon tank with irrigation (2 sprinklers on at a time).

I'll come back for the Cycle Sensor once I get the electrical fixed out there. As it stands, I can only have either 120 or 240 due to a short on one of the original hot wires (black wire). Because of the freezes we get during the winter, I run a small heater out there, so everything is still on 120V. I didn't know this until the new pump was installed and I attempted to connect to 240V. Lots of wasted time that night trying to figure out what the previous owners or installers did.

I am looking at the kit and see the larger the tank, the less the average daily run cycles. Looking at some of the reviews, it seems most folks went with the 4.4 instead of the 10-gallon tank. I also see a few larger tanks used with this system - so the CSV is independent of tank size? Any issues running a 10-gallon tank with irrigation (2 sprinklers on at a time).

I'll come back for the Cycle Sensor once I get the electrical fixed out there. As it stands, I can only have either 120 or 240 due to a short on one of the original hot wires (black wire). Because of the freezes we get during the winter, I run a small heater out there, so everything is still on 120V. I didn't know this until the new pump was installed and I attempted to connect to 240V. Lots of wasted time that night trying to figure out what the previous owners or installers did.

Yes the CSV will work with any size pressure tank. The 4.5 gallon size tanks works for most single family 3-2 houses working a 2HP or smaller pump at 40/60 pressure or lower. I would opt for the 10 gallon tank with a larger house, more than 4-5 people, or when the pressure switch is set at 50/70 or up to 70/90. With 2 to 6 houses on the same system I would go up to a 20 gallon size pressure tank. With larger 3-5 HP pumps I would use a minimum of a 44 gallon size pressure tank, and it will require a larger CSV as well. An 86 gallon size pressure tank is the largest tank needed with even the largest CSV's. I have multiple pump systems with pump sizes up to 200 HP working with a single 86 gallon size tank because they are controlled by a CSV.

On really large water systems like for cities of all sizes, many times the CSV will work without a pressure tank at all. On these large systems the CSV will keep the pump running as long as more than 5 GPM is being used. Cities with more than 100 homes always have at least 5 GPM leaking or being used all the time, so with the CSV working down to 5 GPM, the pump will never fill a pressure tank and shut off anyway, so a pressure tank is not needed. We do this a lot when cities are working on or just painting a water tower. The pumps are fitted with large Cycle Stop Valves and the water tower is completely closed off. Usually before they are finished painting the water tower the city will notice the Cycle Stop Valves cause the pressure to be stronger, the pumps are not cycling and will last longer, and the water hammer has disappeared.

Then I usually get a call from the city water operator asking about this and wondering why they are spending so much fixing the water tower. I always reply with "I don't know why you are working on a water tower as the CSV made water towers and large pressure tanks obsolete almost 30 years ago". There is a lot of money needlessly being spent purchasing and repairing water towers. If your city is still using water towers or huge pressure tanks they are wasting your hard earned tax money. Politics and money not performance are the only reasons why water towers are still being used today.

On really large water systems like for cities of all sizes, many times the CSV will work without a pressure tank at all. On these large systems the CSV will keep the pump running as long as more than 5 GPM is being used. Cities with more than 100 homes always have at least 5 GPM leaking or being used all the time, so with the CSV working down to 5 GPM, the pump will never fill a pressure tank and shut off anyway, so a pressure tank is not needed. We do this a lot when cities are working on or just painting a water tower. The pumps are fitted with large Cycle Stop Valves and the water tower is completely closed off. Usually before they are finished painting the water tower the city will notice the Cycle Stop Valves cause the pressure to be stronger, the pumps are not cycling and will last longer, and the water hammer has disappeared.

Then I usually get a call from the city water operator asking about this and wondering why they are spending so much fixing the water tower. I always reply with "I don't know why you are working on a water tower as the CSV made water towers and large pressure tanks obsolete almost 30 years ago". There is a lot of money needlessly being spent purchasing and repairing water towers. If your city is still using water towers or huge pressure tanks they are wasting your hard earned tax money. Politics and money not performance are the only reasons why water towers are still being used today.

6.7L_MegaCab

New Member

Well, I just finished reading the letters from various manufacturers and articles regarding energy consumption being less because of the way the system operates. Very interesting. I'm going to purchase an ammeter to put out there to monitor everything. I've been wanting to do that anyhow. We do have a second property that we will eventually replace the run-down single wide with a mini-home, but it sounds like a 10-gallon tank will suit us fine for now and upgrade later if needed. With a family of 6 with additional family always visiting throughout the year, we need to keep things running well.

The jet pump is only 3/4 HP, but sounds like it'll be plenty even adding a small home in the future, if not, I'll upgrade it when the time comes. I'm leary about running directly off the submersible pump only because I don't know how reliable the flow has been, despite what the documents say. Being in drought-prone southern NM, I wish I knew where the water actually comes from. The original well went dry when a mountain lake was drained to fight wild fires many years ago.

The jet pump is only 3/4 HP, but sounds like it'll be plenty even adding a small home in the future, if not, I'll upgrade it when the time comes. I'm leary about running directly off the submersible pump only because I don't know how reliable the flow has been, despite what the documents say. Being in drought-prone southern NM, I wish I knew where the water actually comes from. The original well went dry when a mountain lake was drained to fight wild fires many years ago.

Bannerman

Well-Known Member

Water comes from the well, not the tank. The pressure tank's purpose is only to reduce pump cycling.

The minimum recommended run time for a pump is 60 seconds with 120 seconds preffered. If for instance your pump is capable of 15 GPM @ 40/60 psi, then the pressure tank will need to hold 15 gallons liquid for 60 seconds minimum run time or 30 gallons liquid for 120 seconds.

Because a CSV will regulate the flow from the pump to the actual flow rate needed, the pump will not cycle but will continue to run as long as more than 1 GPM is being used. When water is no longer needed, the CSV will allow the pressure tank to fill at only 1 GPM. A 4.5 gallon tank will hold a little more than 1 gallon so that tank will ensure 60 seconds minimum run time whereas a 10 gallon tank will provide 120 seconds minimum run time from that 15 GPM pump.

Because the CSV will not regulate flow until the pump is actually running, using a small tank will ensure the system pressure will rapidly fall to the pump cut-in pressure so further flow will be regulated to a constant pressure by the CSV.

The minimum recommended run time for a pump is 60 seconds with 120 seconds preffered. If for instance your pump is capable of 15 GPM @ 40/60 psi, then the pressure tank will need to hold 15 gallons liquid for 60 seconds minimum run time or 30 gallons liquid for 120 seconds.

Because a CSV will regulate the flow from the pump to the actual flow rate needed, the pump will not cycle but will continue to run as long as more than 1 GPM is being used. When water is no longer needed, the CSV will allow the pressure tank to fill at only 1 GPM. A 4.5 gallon tank will hold a little more than 1 gallon so that tank will ensure 60 seconds minimum run time whereas a 10 gallon tank will provide 120 seconds minimum run time from that 15 GPM pump.

Because the CSV will not regulate flow until the pump is actually running, using a small tank will ensure the system pressure will rapidly fall to the pump cut-in pressure so further flow will be regulated to a constant pressure by the CSV.

Last edited:

6.7L_MegaCab

New Member

Water indeed comes from the well but where that water flows from (before the submersible pump) is what I'd like to know. There is a water association out here that has a very large storage tank that feeds 25 houses. Oddly enough, their mainline runs through my property, but we don't have access to it. The water from their well comes from a natural spring 3 or 4 miles further up the canyon.

I ended up getting the kit and returning those other tanks. Saves me money in the interim and when I can resolve the electrical situation out there, I'll get the cycle saver since it won't work on 120V and repurpose the PumpSaver over to the submersible pump for the well.

I could do an interim fix, but I want to do it right so I can at least have 120 and 240 out there.

I ended up getting the kit and returning those other tanks. Saves me money in the interim and when I can resolve the electrical situation out there, I'll get the cycle saver since it won't work on 120V and repurpose the PumpSaver over to the submersible pump for the well.

I could do an interim fix, but I want to do it right so I can at least have 120 and 240 out there.

Where the water comes from is known in most areas. Some areas it comes from an aquifer. Others it comes from cracks in the rock formation. Still others could be from underground rivers or lakes, witch are sometimes called confined aquafers. Where ever it comes from there are millions of acre feet of water underground, and pressure tanks are never any good at storing water.

6.7L_MegaCab

New Member

Good morning all! I am working on getting the CSV system installed! I hooked up an ammeter to see what the draw is on startup and running - 3 watts on startup and settles at about 2.83 watts until it shuts down. In the week it's been installed, only 0.001 Wh has been recorded. So very little draw. I am curious what the draw will be on 240, so I may convert it over since I'll need to disconnect the electrical again to finish the wall on the right side.

Anyhow...not what I came here for...

Check valves - there is one on the suction side of the pump - a FlowMatic 80SS. The diagram for the CSV has one between the pump discharge and the CSV. Should I relocate the one on the suction side or leave it and install another one on the discharge side or just leave it as is? Just to rehash the current setup: the suction side of the pump is fed directly from a 3K storage tank that is behind me.

Is there a certain type of check valve that is needed? The only one Lowe's has in stock for 1.25" is an American Valve PVC SCH 40 Inline check valve. Will that work or do I need to find something better? I'll head to one of the plumbing outfits here in town if needed.

Also, would you recommend I remove that T that is currently on the pump? I was just going to cut below that first 90, rotate it, and plumb it into the CSV, but since I'll have everything apart, just curious what you would do.

Here's a pic of what I've done so far. I plan on finishing it up today and getting the walls finished once I get that big tank out.

Thanks a ton for all the help so far!

Anyhow...not what I came here for...

Check valves - there is one on the suction side of the pump - a FlowMatic 80SS. The diagram for the CSV has one between the pump discharge and the CSV. Should I relocate the one on the suction side or leave it and install another one on the discharge side or just leave it as is? Just to rehash the current setup: the suction side of the pump is fed directly from a 3K storage tank that is behind me.

Is there a certain type of check valve that is needed? The only one Lowe's has in stock for 1.25" is an American Valve PVC SCH 40 Inline check valve. Will that work or do I need to find something better? I'll head to one of the plumbing outfits here in town if needed.

Also, would you recommend I remove that T that is currently on the pump? I was just going to cut below that first 90, rotate it, and plumb it into the CSV, but since I'll have everything apart, just curious what you would do.

Here's a pic of what I've done so far. I plan on finishing it up today and getting the walls finished once I get that big tank out.

Thanks a ton for all the help so far!

You want a stainless or brass spring loaded poppet style check valve on the suction side of pump. Yeah just rotate tee and connect to the PK1A kit.

6.7L_MegaCab

New Member

Thanks, @valveman! Much appreciated! I saw your message and got right to work when I got home. Everything is up and running! The instructions say that a 10-gallon tank should take about 1 minute and 15 seconds to refill. I timed it a few times yesterday and it is taking about 2 minutes and 30 seconds. This is with a 3/4 HP pump. Is this normal?

I'll go out and double-check again this morning, but I also noticed the pressure was slowly bleeding off. I never noticed this before. Is this a sign that I may have a problem elsewhere in the system or an adjustment just needs to be made?

Lastly, the tank was charged at 35 PSI. The pump is kicking on at 40, holds steady at about 48 PSI, and cuts off at about 58 PSI after the water is turned off. I don't imagine that could cause the above symptoms, but thought I'd add that as well.

Thanks again for all the help! The pump house is way better now and the additional space will be utilized appropriately!

I'll go out and double-check again this morning, but I also noticed the pressure was slowly bleeding off. I never noticed this before. Is this a sign that I may have a problem elsewhere in the system or an adjustment just needs to be made?

Lastly, the tank was charged at 35 PSI. The pump is kicking on at 40, holds steady at about 48 PSI, and cuts off at about 58 PSI after the water is turned off. I don't imagine that could cause the above symptoms, but thought I'd add that as well.

Thanks again for all the help! The pump house is way better now and the additional space will be utilized appropriately!

If you adjust the CSV to hold steady at a higher pressure, maybe at about 53 , I think the run time after using water will decrease. A 2 minute run after water use stops is not a problem.The pump is kicking on at 40, holds steady at about 48 PSI, and cuts off at about 58 PSI after the water is turned off.

Bannerman

Well-Known Member

With a 40/60 pressure switch, the tank will be normally precharged to 38 psi but 35 is often used with a jet pump. A 10-gallon pressure tank will hold approx 2.5 gallons water between 40/60 psi.

With the CSV adjusted to 50 psi, the pressure tank will be approx 1/2 filled when the CSV is regulating flow @ 50 psi. Once water is no longer being used, the remaining 1/2 tank (1.25 gallons) will fill at 1 GPM (= 1 minute 15 seconds) until 60 psi is achieved.

When verifying/adjusting the pressure switch & CSV pressures, ensure the pressure guage is accurate. You may want to obtain a second guage such as one equipped with a garden hose thread so as to compare readings.

With the CSV adjusted to 50 psi, the pressure tank will be approx 1/2 filled when the CSV is regulating flow @ 50 psi. Once water is no longer being used, the remaining 1/2 tank (1.25 gallons) will fill at 1 GPM (= 1 minute 15 seconds) until 60 psi is achieved.

When verifying/adjusting the pressure switch & CSV pressures, ensure the pressure guage is accurate. You may want to obtain a second guage such as one equipped with a garden hose thread so as to compare readings.

Last edited:

6.7L_MegaCab

New Member

Thanks all! I just noticed this. I don't know why I don't get email notifications when there are replies.

I'll get back out there tomorrow or Monday to double-check everything and make some adjustments after getting another gauge to test against. I can see it taking a bit longer if the pressure isn't accurate.

On the plus side, we watched the sprinkler system turn on this morning and it overshot what I had adjusted it to (edge of the yard) and maintained that until the sprinkler system shut off. No more yoyo effect lol.

Another plus, I cleaned up the pump house and finished the inside today, all insulated as well. Now I have a better place to store all of the plumbing and irrigation tools and parts with the extra space.

I'll get back out there tomorrow or Monday to double-check everything and make some adjustments after getting another gauge to test against. I can see it taking a bit longer if the pressure isn't accurate.

On the plus side, we watched the sprinkler system turn on this morning and it overshot what I had adjusted it to (edge of the yard) and maintained that until the sprinkler system shut off. No more yoyo effect lol.

Another plus, I cleaned up the pump house and finished the inside today, all insulated as well. Now I have a better place to store all of the plumbing and irrigation tools and parts with the extra space.

6.7L_MegaCab

New Member

Alright, I went out and made some adjustments yesterday. I found the sheet that shows how to make the adjustments and whatnot-I overlooked it. It seems to be running much better, but more testing to be done. The pressure is holding at 50 PSI and cutting off at 60 within about 1 minute after water use.

I hooked up the ammeter briefly yesterday while a shower was running, clothes washer going, as well as the dishwasher and was quite surprised by the readings, however, once I figure out a way to mount the meters, I'll have a better idea. I'll dig out an actual ammeter as well to compare the readings, but I mounted a pair of these on a generator and they seem quite accurate.

So what are your thoughts on these readings?

Prior to the CSV being installed, the pump was hooked up to 120V. The power at pump start was 3 watts and while running until the 80-gallon pressure tank filled, settled to 2.83 watts. This was observed over a few days.

This is what was recorded, pump on 240V, after final CSV adjustments and PumpSaver hooked up, the pressure from the pump was reading about 70 PSI:

Line 1:

Line 2:

I hooked up the ammeter briefly yesterday while a shower was running, clothes washer going, as well as the dishwasher and was quite surprised by the readings, however, once I figure out a way to mount the meters, I'll have a better idea. I'll dig out an actual ammeter as well to compare the readings, but I mounted a pair of these on a generator and they seem quite accurate.

So what are your thoughts on these readings?

Prior to the CSV being installed, the pump was hooked up to 120V. The power at pump start was 3 watts and while running until the 80-gallon pressure tank filled, settled to 2.83 watts. This was observed over a few days.

This is what was recorded, pump on 240V, after final CSV adjustments and PumpSaver hooked up, the pressure from the pump was reading about 70 PSI:

Line 1:

Line 2:

Numbers look good. Note the Wh is what you pay for (kWh is 1000 Wh), and that number is not going to be much I expect.So what are your thoughts on these readings?

What is that monitor? Impressive.

6.7L_MegaCab

New Member

Numbers got me again. kWh...I read that number as that, but it isn't that...oops. Good call!

Glad the numbers are good though. Going from a couple of watts to over 1K watts had me concerned a bit.

These are the MICTUNING branded meters. Got them on Amazon. The ones on the generator are CrocSee branded. Both look exactly alike and seem to work pretty well.

Thanks for the info! Y'all have been great and everything is running tiptop now!

Glad the numbers are good though. Going from a couple of watts to over 1K watts had me concerned a bit.

These are the MICTUNING branded meters. Got them on Amazon. The ones on the generator are CrocSee branded. Both look exactly alike and seem to work pretty well.

Thanks for the info! Y'all have been great and everything is running tiptop now!

Similar threads

- Replies

- 10

- Views

- 608

- Replies

- 14

- Views

- 386

- Replies

- 1

- Views

- 146

- Replies

- 2

- Views

- 150