longfemur

New Member

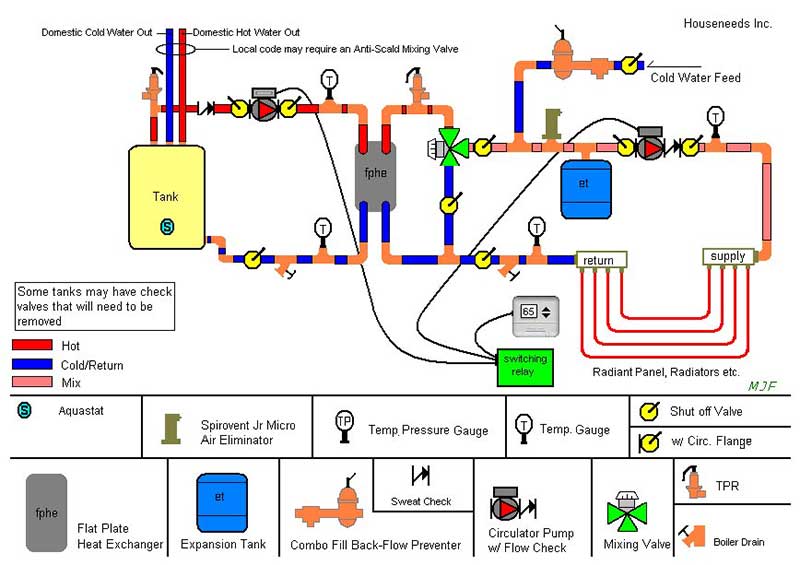

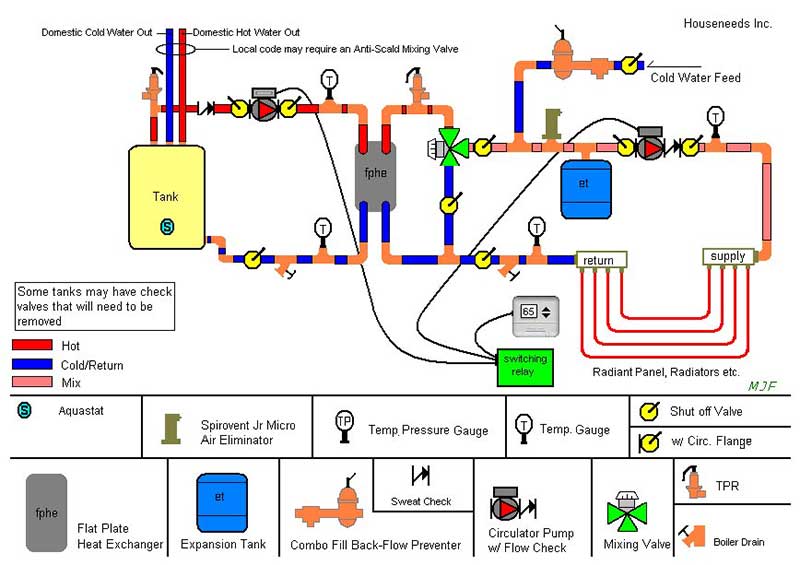

I've been eyeing using a high BTU hot water tank heater (like the HTP Phoenix Light Duty) for DHW and space heating (via heat exchanger) for our home. Our home has a 60k heating load on a not too conservative design day (-13C for Toronto, Ontario). I've seen this (below) design diagram floating around on this forum, but haven't seen specifics or discussion regarding the best way to control the space heating side water temperature of the system.

Background:

Our (old) brick home is basically completely uninsulated (other than the roof), but we'll be slowly insulating parts of the house, and replacing windows, starting with the basement later this fall. We have 2 bathrooms, and 5 people living at the house. Showers already have low flow heads so our domestic hot water use should be reasonable, meaning that together with our heating load, we should be able to squeak by with a phoenix light duty hot water tank (25-75k BTU, 50 gallon) with maybe some slightly tepid water on design days this winter. On the heating side of our setup, we will have 3 zones (one for each floor) controlled by zone valves and a constant pressure pump. Our floors are hardwood, so an important part is not to overheat these floors (we’ll have a couple slab sensors our our thermostats).

Question:

My question isn't about whether the domestic hot water tank / heat exchanger setup would suit our needs, but is actually about how to control the pumps and, particularly how to control the water temperature in this kind of setup. Specifically, how is the temperature of space heating side water controlled?

Tentative answers:

My assumption is that the DHW tank could be setup for around 140F all year round. The tank and heating side circulators would both be called on the same schedule by the thermostats/tekmar zone control. I guess the idea with the 3-way mixing valve in the diagram is that it would have some kind of outdoor temp reset, so that the space heating water isn't circulated at an unnecessarily hot temperature on relatively warm days and vice versa, so that the space heating pump can run relatively constantly. I guess the tank side circulator for this setup would be a constant speed, and would be sized to provide sufficient heat exchange for a design day. Isn't it inefficient to use a mixing valve though and wouldn't this cause the space heating side to short cycle?

Wouldn't a better option than a mixing valve be to use a variable speed tank pump that would run slowly on relatively warm days, and run fastest on design days, according to some outdoor reset curve? This would be analogous to a boiler that modulates according to an outdoor reset curve. This would mean that more heat would be exchanged to the space heating loop on colder days.

Costing/specifics of the alternatives:

Mixing valves with outdoor reset (https://www.supplyhouse.com/Taco-I0...eset-I-Series-Mixing-Valve-w-Sensor-5203000-p). A fine option, I guess, but seems overpriced given that it isn't really an ideal solution in my mind.

Variable speed pumps with outdoor reset ... this specific example (link below) is not ECM and not suitable for domestic hot water ... would need to figure out how to rig with a temp sensor (http://www.blueridgecompany.com/rad...o-variable-speed-variable-voltage-circulators). There seem to be Tekmar controls designed to control pumps for heat exchangers but the use case isn't the same as ours (http://www.tekmarcontrols.com/images/_literature/157_d_06.pdf) . The vast number of alternatives is a little baffling to me, but seems like there should be a simple, not-too-expensive, and efficient solution that's escaping me.

The Taco XBlock is designed for exactly this kind of setup, but wouldn't have the capacity for our home (max 50k BTU/h).

Any feedback on a specific way of controlling this system that is efficient (in terms of both up front cost and long run gas consumption) and comfortable would be appreciated!

Background:

Our (old) brick home is basically completely uninsulated (other than the roof), but we'll be slowly insulating parts of the house, and replacing windows, starting with the basement later this fall. We have 2 bathrooms, and 5 people living at the house. Showers already have low flow heads so our domestic hot water use should be reasonable, meaning that together with our heating load, we should be able to squeak by with a phoenix light duty hot water tank (25-75k BTU, 50 gallon) with maybe some slightly tepid water on design days this winter. On the heating side of our setup, we will have 3 zones (one for each floor) controlled by zone valves and a constant pressure pump. Our floors are hardwood, so an important part is not to overheat these floors (we’ll have a couple slab sensors our our thermostats).

Question:

My question isn't about whether the domestic hot water tank / heat exchanger setup would suit our needs, but is actually about how to control the pumps and, particularly how to control the water temperature in this kind of setup. Specifically, how is the temperature of space heating side water controlled?

Tentative answers:

My assumption is that the DHW tank could be setup for around 140F all year round. The tank and heating side circulators would both be called on the same schedule by the thermostats/tekmar zone control. I guess the idea with the 3-way mixing valve in the diagram is that it would have some kind of outdoor temp reset, so that the space heating water isn't circulated at an unnecessarily hot temperature on relatively warm days and vice versa, so that the space heating pump can run relatively constantly. I guess the tank side circulator for this setup would be a constant speed, and would be sized to provide sufficient heat exchange for a design day. Isn't it inefficient to use a mixing valve though and wouldn't this cause the space heating side to short cycle?

Wouldn't a better option than a mixing valve be to use a variable speed tank pump that would run slowly on relatively warm days, and run fastest on design days, according to some outdoor reset curve? This would be analogous to a boiler that modulates according to an outdoor reset curve. This would mean that more heat would be exchanged to the space heating loop on colder days.

Costing/specifics of the alternatives:

Mixing valves with outdoor reset (https://www.supplyhouse.com/Taco-I0...eset-I-Series-Mixing-Valve-w-Sensor-5203000-p). A fine option, I guess, but seems overpriced given that it isn't really an ideal solution in my mind.

Variable speed pumps with outdoor reset ... this specific example (link below) is not ECM and not suitable for domestic hot water ... would need to figure out how to rig with a temp sensor (http://www.blueridgecompany.com/rad...o-variable-speed-variable-voltage-circulators). There seem to be Tekmar controls designed to control pumps for heat exchangers but the use case isn't the same as ours (http://www.tekmarcontrols.com/images/_literature/157_d_06.pdf) . The vast number of alternatives is a little baffling to me, but seems like there should be a simple, not-too-expensive, and efficient solution that's escaping me.

The Taco XBlock is designed for exactly this kind of setup, but wouldn't have the capacity for our home (max 50k BTU/h).

Any feedback on a specific way of controlling this system that is efficient (in terms of both up front cost and long run gas consumption) and comfortable would be appreciated!

Last edited by a moderator: