Hi all,

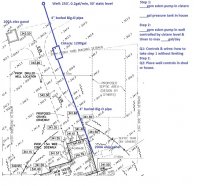

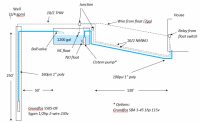

I'm new to the world of wells and could use some advice. The local well contractors are giving me conflicting opinions. I have literally sunk a lot of dollars into a 250' well that only produces less than 1/4 gpm. I then had a 1200gal concrete cistern set about halfway along a total run of about 200'. The cistern is slightly uphill of the house. All are connected underground with 4" Big-O, but no water pipe of wires yet have been pulled. I am thinking about breaking the project into 2 stages, the first being the installation of a sub pump in the cistern to feed a pressure tank in the house (4bdrm 3.5bath) and then having water delivered by truck. At some point in the future, Step 2 would be to put a pump in the well to feed the cistern, along with a float switch. Valveman has helpfully posted a diagram with just that type of set up. My question is whether it makes sense to install the well pump to a electronic timer so that it refills say a max number of gallons per night (let's say 150gal). Most of the time the house will only have 2 ppl and usually only on weekends, so I don't foresee water shortages. The reason for holding off on step 2 is because both contractors recommend abandoning the well--1 says flow OK, but quality bad and other says flow bad and quality OK. --I need more time to properly evaluate it.

Any thoughts on how to proceed with Step 1 without screwing up Step 2?

I'm new to the world of wells and could use some advice. The local well contractors are giving me conflicting opinions. I have literally sunk a lot of dollars into a 250' well that only produces less than 1/4 gpm. I then had a 1200gal concrete cistern set about halfway along a total run of about 200'. The cistern is slightly uphill of the house. All are connected underground with 4" Big-O, but no water pipe of wires yet have been pulled. I am thinking about breaking the project into 2 stages, the first being the installation of a sub pump in the cistern to feed a pressure tank in the house (4bdrm 3.5bath) and then having water delivered by truck. At some point in the future, Step 2 would be to put a pump in the well to feed the cistern, along with a float switch. Valveman has helpfully posted a diagram with just that type of set up. My question is whether it makes sense to install the well pump to a electronic timer so that it refills say a max number of gallons per night (let's say 150gal). Most of the time the house will only have 2 ppl and usually only on weekends, so I don't foresee water shortages. The reason for holding off on step 2 is because both contractors recommend abandoning the well--1 says flow OK, but quality bad and other says flow bad and quality OK. --I need more time to properly evaluate it.

Any thoughts on how to proceed with Step 1 without screwing up Step 2?