Joseph Skoler

Member

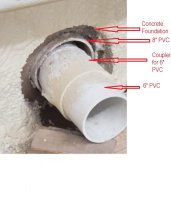

I cut a 10" diameter hole in my foundation wall to slide an 8" PVC pipe to be used as a sleeve to hold a 6" PVC sewage drain pipe.

I need to seal (water-tight) between the concrete and the 8" PVC sleeve, and between the sleeve and the 6" PVC pipe.

I've seen recommendation for expanding foam and polyurethane sealer, as well as hydaulic cement and other solutions.

Unfortunately, the pipes are already run and only after spray foaming the basement walls and around the pipes did I find out that water is seeping in.

So I cut out all the foam on the inside and dug up the pipe on the outside.

Can I just use a product like Sika 1A poly sealer?

What would all your much more experienced people do?

Thank you!

I need to seal (water-tight) between the concrete and the 8" PVC sleeve, and between the sleeve and the 6" PVC pipe.

I've seen recommendation for expanding foam and polyurethane sealer, as well as hydaulic cement and other solutions.

Unfortunately, the pipes are already run and only after spray foaming the basement walls and around the pipes did I find out that water is seeping in.

So I cut out all the foam on the inside and dug up the pipe on the outside.

Can I just use a product like Sika 1A poly sealer?

What would all your much more experienced people do?

Thank you!