Phoenix2099

New Member

Hi everyone, I need some help/advice/guidance on my shallow well and irrigation pump set-up.

I purchased my house a few years ago, and was told by the sellers that there was a shallow well underneath a shed in the back yard. Knowing nothing about wells, I did not know what questions to ask. Similarly, never having irrigation before, when I called around to have sprinklers put in, I took the company at their word that what was being done was adequate.

Fast forward a few years, (and a several issues later), and here I am-needing to replace the pump (at a minimum), or re-do the entire setup (new well, plumbing, pump, etc.) Some of the issues included: losing prime frequently each season (from leaks in PVC connections); shallow well drying up/pump unable to pull any water; crack/complete disconnection of the PVC piping at the check valve; crack in the neck of electronic control panel.

Since I do not know much about the set-up, I am posting pictures of what things look like now. I will say that in the past when I have called around to companies that did well work, and sent them pictures, each of them said what a terrible set-up I had. But none were willing to do anything about it. So I need to figure out what exactly the issues are, and what, if anything, I can do about them.

What I know: there is a shallow well under the shed. (How deep it is, what the water table is, and how old the pipe is, are all things I do not know.)

What else I know: the shallow well is used solely for irrigation. There are four sprinkler zones, with varying heads in each zone, anywhere from 2-5. When it does operate properly, the pump kicks on when the irrigation is turned on, or when I open up the spigot (before the sprinklers).

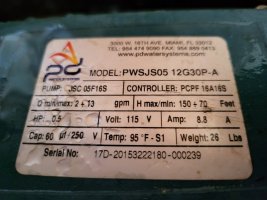

The pump is a PD Water Systems PWSJS05 12G30P-A (0.5HP, 12GPM, 30PSI), with a Presflo Electronic Pump Controller # PCPF 16A16S.

So my questions are: what things are wrong with this set-up, and how can I remedy them? (Note that I have the filter removed, but there normally is one in place). Since the housing of the electronic pump controller is broken and needs to be replaced, should I get a different kind of electronic pump controller, or scrap that part all together, and if so, what should it be replaced with? Also, is this (or any) pump operational without an electronic control valve?

My initial plan was to just replace what I have with a newer version of the same set-up, since it is all I know. But after having companies tell me what a disaster everything is, I am thinking of basically starting over. Any advice is helpful at this point. I have reached out to tons of companies, and all have been too busy to come out to even give a quote on doing any work, so I am lost to say the least.

Thanks so much in advance everyone.

I purchased my house a few years ago, and was told by the sellers that there was a shallow well underneath a shed in the back yard. Knowing nothing about wells, I did not know what questions to ask. Similarly, never having irrigation before, when I called around to have sprinklers put in, I took the company at their word that what was being done was adequate.

Fast forward a few years, (and a several issues later), and here I am-needing to replace the pump (at a minimum), or re-do the entire setup (new well, plumbing, pump, etc.) Some of the issues included: losing prime frequently each season (from leaks in PVC connections); shallow well drying up/pump unable to pull any water; crack/complete disconnection of the PVC piping at the check valve; crack in the neck of electronic control panel.

Since I do not know much about the set-up, I am posting pictures of what things look like now. I will say that in the past when I have called around to companies that did well work, and sent them pictures, each of them said what a terrible set-up I had. But none were willing to do anything about it. So I need to figure out what exactly the issues are, and what, if anything, I can do about them.

What I know: there is a shallow well under the shed. (How deep it is, what the water table is, and how old the pipe is, are all things I do not know.)

What else I know: the shallow well is used solely for irrigation. There are four sprinkler zones, with varying heads in each zone, anywhere from 2-5. When it does operate properly, the pump kicks on when the irrigation is turned on, or when I open up the spigot (before the sprinklers).

The pump is a PD Water Systems PWSJS05 12G30P-A (0.5HP, 12GPM, 30PSI), with a Presflo Electronic Pump Controller # PCPF 16A16S.

So my questions are: what things are wrong with this set-up, and how can I remedy them? (Note that I have the filter removed, but there normally is one in place). Since the housing of the electronic pump controller is broken and needs to be replaced, should I get a different kind of electronic pump controller, or scrap that part all together, and if so, what should it be replaced with? Also, is this (or any) pump operational without an electronic control valve?

My initial plan was to just replace what I have with a newer version of the same set-up, since it is all I know. But after having companies tell me what a disaster everything is, I am thinking of basically starting over. Any advice is helpful at this point. I have reached out to tons of companies, and all have been too busy to come out to even give a quote on doing any work, so I am lost to say the least.

Thanks so much in advance everyone.