Paul Reece

New Member

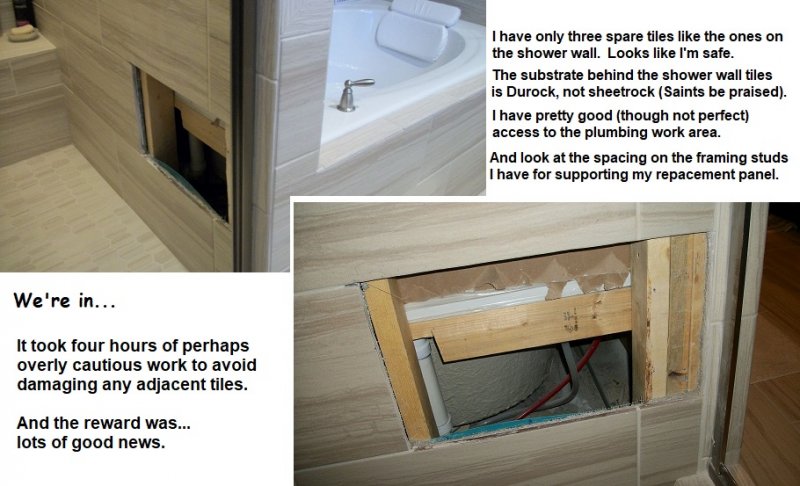

My best access to the faucet/filler plumbing of my bathtub was through the wall of the adjacent shower stall.

That wall is tiled with large 12 x 24 ceramic tiles. I was successful in cutting out one complete tile and its substrate (something similar to Durock) without damaging surrounding tiles, but now that my renovation to the plumbing is done, I have to rebuild that opening. I face a series of challenges, and a couple of them leave me uncertain.

1.) I have augmented (not shown in photo) the framing members I found inside the wall to assure generous, rigid support for the 1/2" Durock I will use as replacement substrate. But since the edge seams of that replacement panel will exactly coincide with the eventual grout seams around the replacement tile, I want to be sure it offers no opportunity for leakage into the wall. Seam tape appears to be kinda pointless since I can't bridge the gap between the old Durock and the new (only one side of that gap is accessible). I thought I might squeeze caulk into the joint and rub it in as deeply as possible while smoothing it to flush with the Durock surface.

2.) It's such a small replacement job, I thought I might use a pre-mixed mastic to adhere the wall tile, but it's such a large single tile at 12 x 24, I worried about the mastic setting up properly and/or in a reasonable span of time. Adhesives sandwiched between cement board and ceramic tile don't encounter an arid "drying" environment, and from what I've read about mastics, they don't have an actual "curing" process.

Any thoughts and recommendations will be appreciated I'll wait for advice before commencing the repair.

(Photo is part of a Facebook post from back when I was much more enthusiastic about this whole project.)

I sistered that stud on the left by sliding a 12" upright around it to the far (left) side, snugging it up to the back of the substrate and screwing through the two members.

I installed secure, rigid horizontals across the opening at the top and the botom, snugging them up to the backside of the original substrate and sharing the width of the lumber's bearing surface half-and-half between the old Durock and where the new Durock will be. Then I put an upright between the top and bottom crossmembers.

That wall is tiled with large 12 x 24 ceramic tiles. I was successful in cutting out one complete tile and its substrate (something similar to Durock) without damaging surrounding tiles, but now that my renovation to the plumbing is done, I have to rebuild that opening. I face a series of challenges, and a couple of them leave me uncertain.

1.) I have augmented (not shown in photo) the framing members I found inside the wall to assure generous, rigid support for the 1/2" Durock I will use as replacement substrate. But since the edge seams of that replacement panel will exactly coincide with the eventual grout seams around the replacement tile, I want to be sure it offers no opportunity for leakage into the wall. Seam tape appears to be kinda pointless since I can't bridge the gap between the old Durock and the new (only one side of that gap is accessible). I thought I might squeeze caulk into the joint and rub it in as deeply as possible while smoothing it to flush with the Durock surface.

2.) It's such a small replacement job, I thought I might use a pre-mixed mastic to adhere the wall tile, but it's such a large single tile at 12 x 24, I worried about the mastic setting up properly and/or in a reasonable span of time. Adhesives sandwiched between cement board and ceramic tile don't encounter an arid "drying" environment, and from what I've read about mastics, they don't have an actual "curing" process.

Any thoughts and recommendations will be appreciated I'll wait for advice before commencing the repair.

(Photo is part of a Facebook post from back when I was much more enthusiastic about this whole project.)

I sistered that stud on the left by sliding a 12" upright around it to the far (left) side, snugging it up to the back of the substrate and screwing through the two members.

I installed secure, rigid horizontals across the opening at the top and the botom, snugging them up to the backside of the original substrate and sharing the width of the lumber's bearing surface half-and-half between the old Durock and where the new Durock will be. Then I put an upright between the top and bottom crossmembers.