The high delta-T just means that enough heat is leaving the tubing to drop the temperature, but doesn't indicate where that heat is going. With even R13 insulation between the tubing and the ceilings below it's typically less than 10% of the total going into the "wrong" heating zone.

Dribbling along at 0.5 gpm = 250 lbs/hr and a 30F delta-T you're looking at 30F x 250lbs/hr= 7500 BTU/hr. Bump that to 2 gpm (1000 lbs/hr) and a 10F delta-T it's 1000lbs x 10F= 10,000 BTU/hr, 33% more heat.

Your pumping head may or may not be too high on the Main zone to even hit 2 gpm with a reasonable sized pump, but do the math. The Taco 0012 is only good to about 15' of head, more of a high-flow/modest head type of pump designed to push Niagra falls type flows through fat plumbing. The 007 is good for only 10' of head but lower flow. Calculate the pumping head on your longest tubing runs at 1 gpm & 2 gpm using

this quick & dirty online calculator. (<< only to ballpark it) . At 2 gpm 300' of half inch is over 10' of head, even if perfectly straight- you may be able to squeak better than 1 gpm out of a Taco 007, but not 2. With the 0012 you'd be able to get better about 2-2.2 gpm on a 300' loop.

This is why it's easier to get there brute-forcing it with an individual pump per zone. The shorter-tubing zones might still be fine sharing a pump, but probably not the longer zones. Smart ECM drive pumps that display the gpm can be very useful for dialing these things in, but they're pricey.

The maximum advisable gpm on half inch PEX is 2.3 gpm, so you'd still be good to go on the higher-head loops, but would have to throttle back the lower head loops. With 6 zones you don't need or want more than about 12 gpm of flow total. For less money than the 0012, the

Viridian 2218 is a higher head/lower flow type pump that can probably handle this, and can be tweaked in several ways to deliver enough to each zone without delivering too much. At 10' of head it can deliver about 10gpm, whereas the 007 is gasping to deliver 2 gpm even at 9 feet of head which is why all your longer zones are starved for flow. (With apologies for the less-considered Viridian 3452 random monster pump earlier), a

Viridian 2218 operated under delta-T control on the manifolds would almost certainly make a reasonable secondary/radiation pump on this system if you're keeping the zone valves and doing the radiation with a single pump. Even at max speed it draws less power than the 007, but under delta-T control it will throttle back to even lower power (and lower gpm) when zone valves close, which avoids the over pumping issue with lower head zones. There will still be manual zone-flow tweaking to throttle back the lower head zones, but you'll be starting from an easier place.

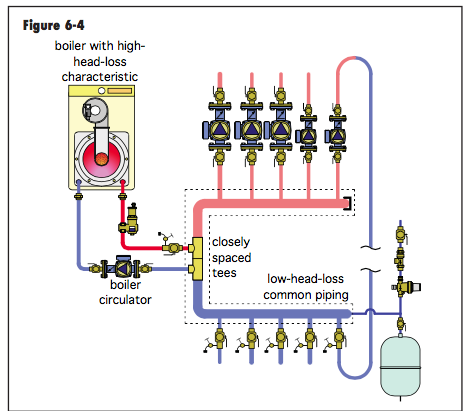

And you'll still want to set up the primary loop with it's own pump, and probably a massive hydraulic separator to tame the short cycling.

The heat loss of basement rooms in house with a code-min full height foundation wall insulation are pretty tiny, so even throttling that down to 0.5 gpm or less may still heat those rooms, and it's usually easy to add more baseboard if/where necessary to do it.

Clearly if the boiler is short cycling not even half the boiler's potential output is going into the zones. The only way of getting more into the zones is higher flow. Once you get the flow into the radiation high enough to actually heat the place at the 99% outside design temp (assuming that's even possible with the radiation design) it will be time to address the short-cycling. With more heat going into the zones the burn times will lengthen, but probably not enough to fully suppress the short-cycling on this way-oversized boiler.

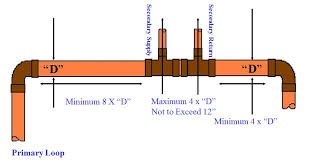

Using an electric water tank as the hydraulic separator works fine at 10-12 gpm, using the upper and lower heating element ports as the primary loop connections (boiler output goes into the top heating element port), and the cold & hot connections (or the drain and hot connection) as the secondary side connections. (Think of it as a really FAT closely spaced tee.)

Using the existing Taco 007 to drive the loop through the tank to the BW9-150 will run at about 8-10 gpm , or 67-83lbs per minute when it has just the pumping head of the BW9 to deal with. At 135,000 /BTU/hr = 2250 BTU/minute and 67lbs/minute flow there would be 2250/67= 34F delta T across the boiler, which is fine. At 83lbs/minute the delta-T across the boiler would be 27F, which is also fine. If in practice the delta turns out to be less than 10F the boiler flow can be throttled back to deliver more. If it's over 50F at the boiler a bigger primary pump is called for.

The curve indicated on page 6 seems odd, almost as if the axis' are mislabeled, but at 8' of head there's 9 gpm of flow, which is in the right range for the

Taco 007, which delivers about 8gpm at 8' of head.

Is the UltraFin laid out with tubing ~32" on center perpendicular to the joists, with a fin in every joist bay? Or is the tubing parallel to the joists, with fins 36" on center?