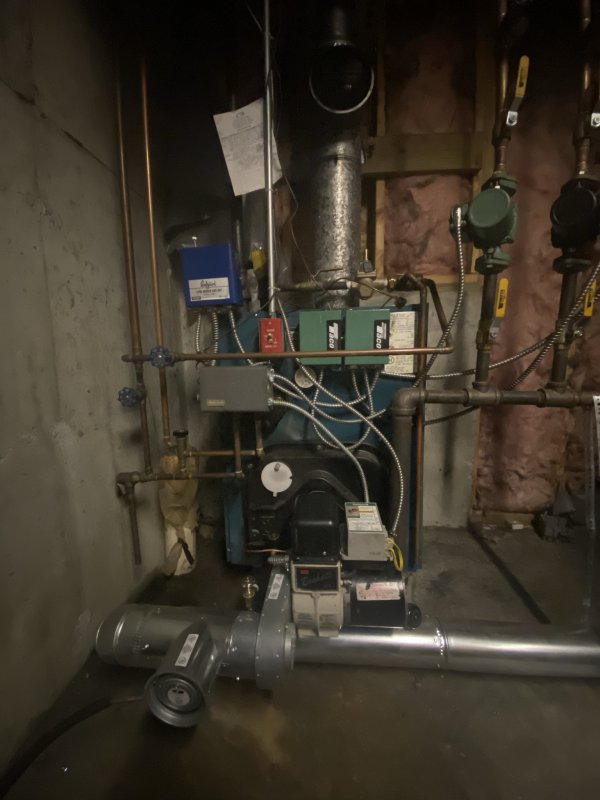

I have a 20 year old boiler with tankless hot water. Hot Water Performance always was bad. I'm thinking of getting a hybrid water heater and bypassing the boiler altogether.

Who should I bring in to revise the plumbing to the boiler and new water heater? Plumber or boiler tech?

Just about any competent plumber in Maine would be able to correctly install the hybrid water heater and cap off the tankless coil in the boiler. The boiler will continue to work just fine with the domestic hot water disconnected from the tankless coil. The controls for the coil are pretty dumb, amounting to setting the minimum idling temperture.

But a boiler tech would be the person to advise on how to adjust (or even replace) the controls on the boiler for higher efficiency. A heat purging economizer control can save quite a bit on oil use by reducing the average boiler temp, which can now be much lower if it's not serving up hot water. That part not really plumbing job.

A hot boiler in a poorly insulated basement boiler room means a large amount of the idling loss heat is truly lost. In order to serve up hot water at any reasonable rate the idling temp of the boiler has to be fairly high, which results in much higher jacket losses to the boiler room, which doesn't appear to have any insulation on the foundation walls(?), and no interior vapor or air barriers on the framed exterior wall (?). But even with a cold-start boiler and no tankless coil those losses are pretty high, easily accounting for a double-digit percentage of your overall oil uses, even when not actively heating the basement.

When re-plumbing the near-boiler if the pipes can be moved to provide sufficient clearance to install 2.5" of foil-faced rigid polyiso (R15) on the foundation wall (R15 continuous insulation is current IRC code minimum in your climate zone) those losses can be reduced dramatically. To be fire-safe there needs to be a thermal barrier against ignition (half inch wallboard glued to the foam works, or mounting on strapping through-screwed to the foundation with masonry screws), and the area around the flue pipe would need to be R15 rock wool (and NOT fiberglass or foam). Check local codes on how much clearance from combustibles when insulating around flues. Some local codes would allow contact with rock wool (which has a melting temp higher than steel), others would still require some air clearance from the pipe.

The pink fiberglass open to the boiler room air without an air barrier or vapor retarder creates high wintertime moisture levels in the exterior sheathing of the framed wall portion. At the very least the fiberglass needs to be re-installed for snug fit (for R-performance) with no compressions or voids, covered with air tight latex painted wallboard (about 3-5 perms) but it probably needs "vapor barrier latex" primer (about 0.5 perms) , or 4-6 mil polyethylene (0.05-0.1 perms) or a "smart" variable permeance vapor retarder to reduce moisture risk. The approach that makes the most sense depends on the material stackup of the sheathing, weather barrier & siding, and your budget. But what you have now is fairly high risk for developing mold conditions on part (or all) of the exterior sheathing.