John Gayewski

In the Trades

Your ruining your pumps.

You gotta keep reading. Effeciancy goes down as move away from the middle of the curve. Which means the second pump is doing nothing.Pumps in series double the head gpm stays the same.

Solenoid valves brand, model and pipe size pipe?Plumbing & Mechanical Engineer | Plumbing & Mechanical

Comprehensive source for engineers and designers: Plumbing, piping, hydronic, fire protection, and solar thermal systems.www.pmengineer.com

I am definitely not qualified to debate this with you and you and John could well be correct that I'm destroying the pumps. Two points here.I agree with John that in a closed loop system, pumps in series will not have the effect you think. As he explains, the water has nowhere to go except back to the first pump. The system will get to equilibrium pretty fast.

That said, as soon as you open a faucet, it is no longer a closed loop. In this case, you might see a benefit from pumps in series as you have observed.

U.S. Solid 3/4' 110v Normally Closed. Pex is 3/4"Pumps in series double the head gpm stays the same.

Solenoid valves brand, model and pipe size pipe?Plumbing & Mechanical Engineer | Plumbing & Mechanical

Comprehensive source for engineers and designers: Plumbing, piping, hydronic, fire protection, and solar thermal systems.www.pmengineer.com

Good catch. Note the pictures are the old design and the current revised design where the check valves are gone. The solenoid valves came after the system was built because of a sporadic problem with water temperature. So yes I could have removed the check valves then but I didn't. What lead to the redesign is that I realized with the solenoid valves I could use a common motor rather than one for each zone. Then I thought why not try two motors and while making that change I removed the check valves.Mechanical engineer that works in the hvac could figure this out. Never have I've seen solenoid valves and check valves together. Every device that is piped in a system is a pressure drop including 90°s and the size of the pipe. You have spent more on pumps, check valves and solenoid valves than what could be your payback. Sorry i don't understand reinventing the wheel with a return line. Most people want hot water at certain times 5 am to 7 am and 5 pm to 10pm, 7 hours a day. Hot button going to use a sink or shower turn on a light switch on ,pump comes on, use the toilet need the shower ,sink leave light goes off pump turns off. Why aren't the return lines insulated if your looking for being energy efficient?

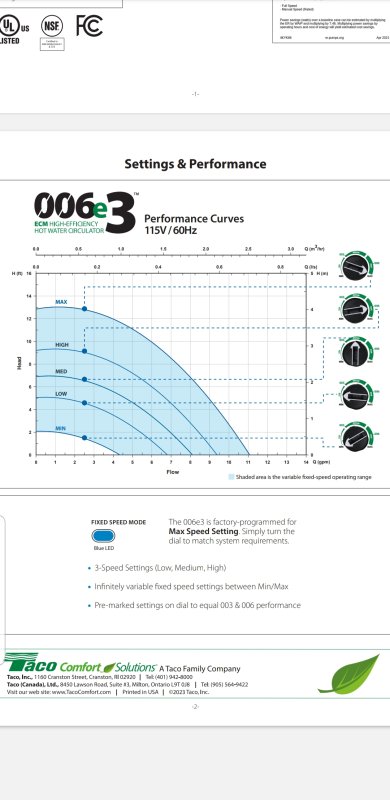

John, here's some new differential pressure information below. But to answer your questions, Pumps are on MAX setting. Your comment about pro's not doing this sort of thing was why I did it myself. And one pump or two pumps I've VERY HAPPY that I did.If 5gpm is right (which I don't think it is) you would be within range at about 4.4 ft per second.

But your pump curve would say your wrong.

Which setting are these pumps on?

We're out of range for normal here so asking a group who doesn't do this kind of stuff (yet still has happy customers) means you might not get the answer you want.

You could have on demand hot water circulation with an occupancy sensor and half of the components and none of the maintenence.

No one would do this with such a small amount of head. Your only overcoming 150' of resistance.

Those solenoid valves are not for potable water and most likely don't meet the lead free standards.U.S. Solid 3/4' 110v Normally Closed. Pex is 3/4"

https://www.amazon.com/gp/product/B007N0J98E/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1

Thanks and I'm well aware of that. The hot water which is also softened doesn't get consumed in this house. I have a pot filler faucet supplied with city water for that.Those solenoid valves are not for potable water and most likely don't meet the lead free standards.

Where do you come up with 5' of head? Doesn't the differential pressures (4psi with one pump and 8psi with two pumps) say otherwise? My estimates based on these differential pressures are about 9' of head and 20' of head for one and two pumps. Based on that I estimate about 3.5GPM for one pump and a little over 5gpm for two pumps.Let's think of this a different way. 150' of 3/4" pex only has 2.6 gal of water in it.

One pump on high (turned all the way up) with 5ft of head can move 9gpm.

9 gallon in sixty seconds is 1.5 gallons in ten seconds. That should get you to your sink.

So if your right your torching your piping and your getting way more than 5 gpm more like 18 gpm. Piping is getting hammered. Pumps hammered. Noise is velocity noise.

So you say I'm only using it a little bit. Does it hurt to run sandpaper through your piping? Even if you only do it five times a day? Yes.

Yes, I figured out a while ago the .03 made no sense. My current estimate is .0525 with the two pumps.The head goes up as you add speed so the 0.03 number I gave you only applies at normal velocities. That is a design number used for head at speeds below what is normal design.

You would max the speed for pex with one pump turned all the way up.

You have a lot of components on your system. Even with a safe multiplier of 1.5 your still only at 6.75 ft of head.Yes, I figured out a while ago the .03 made no sense. My current estimate is .0525 with the two pumps.

If I were maxing the speed for pex with one pump turned all the way up I would have hot water faster than I dreamed. But that's not happening so I'm thinking you're making an incorrect assumption somewhere. I'm guessing from your other post that your 5" of head is the culprit. Doesn't the differential pressure clearly show 5' of head isn't realistic?

This is awkward, but...

It looks like you're using an ad blocker. We get it, but (1) terrylove.com can't live without ads, and (2) ad blockers can cause issues with videos and comments. If you'd like to support the site, please allow ads.

If any particular ad is your REASON for blocking ads, please let us know. We might be able to do something about it. Thanks.