Frank Lartone

New Member

Hello,

If anyone would like to offer some ideas that I can implement, I would be grateful.

I have a 3350sq house with an approx 2000sqft walk out basement. House has full radiant floor on the upper two levels and the basement has no dedicated heat supply. The basement stays in the upper 50's typically as the 3/4" copper hydronic pipes feeding the zones are exposed and although the joists are insulated with fiberglass, enough heat escapes the floor above to moderate the cellar temp.. The radiant is divided into 5 zones. This was a DIY from 20 years ago. A Monitor MZ25, wall hung, condensing boiler has been in place since built. It has been struggling with various issues and last night the igniter stopped functioning. It will not be repaired as there are combustion chamber fractures and today it was removed.

I have a Westinghouse WBRCLP140 that was purchased 2 years ago, but has never been commissioned. I would like to put this boiler in the system. I thought , when I purchased it that the 10:1 turn down ratio would make a good fit. I don't know now. The more I read the less I know.

Calculated heat loss from walls windows and ceiling, including basement is approximately 51Kbtu. This does not include any loss from air exchange. The 5 zones are approx, without account for air infiltration, 7.4Kbtu, 5.4Kbtu, 4.3Kbtu, 10.5Kbtu, 13.5Kbtu. The basement adds 9.4Kbtu.

Each zone is 4, 5 or 6 loops of 1/2" pex on top of plywood sub-floor in 2" gypcrete. Typical loop is 100'-140', IIRC run off of Wirsbo mainfolds with each loop having an adjusting valve. The main manifold off the boiler is regulated by Taco zone valves and zone control.

So my question comes in regarding water distribution. I don't have much of a grasp on this part of the system, but I would like to add to it if that is appropriate (both my grasp and the hardware). There has been no mixing valve or primary/radiant loop or close proximity Ts or buffer tank or any kind of water diversion in the system so the heated water has been fed directly into the distribution manifold that sits next to the boiler. The old boiler had a circulating pump and there was another circulating pump prior to the zone valves. I guess the house has typically been comfortable, but from what I am reading lately, it seems the water distribution isn't designed as it should be.

The previous boiler was not modulating and there were times when short cycling was an issue. Output temp has been run between 117F and 125F over the years. Last year I had been opening a couple zone valves manually because the wax motors failed. This was kind of a good thing as the short cycling was somewhat mitigated, I suppose because it made a larger zone by combining them.

I would like to get this straightened out as best I can, even if the distribution isn't perfect. I can do the installation with some good advice. Once I have it set up as best I can, I'll have someone come in and inspect the gas fittings and get the initial fire up.

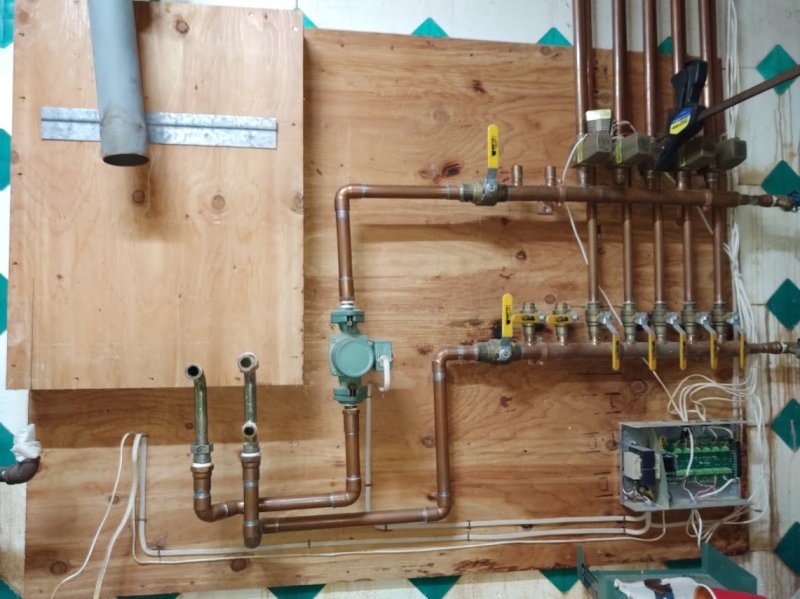

Here is the existing distribution with a Taco 007-F5. There is a Grundfos Type UPS 15-42 F I took out of the old boiler available as well.

Thanks again for any interest and help.

If anyone would like to offer some ideas that I can implement, I would be grateful.

I have a 3350sq house with an approx 2000sqft walk out basement. House has full radiant floor on the upper two levels and the basement has no dedicated heat supply. The basement stays in the upper 50's typically as the 3/4" copper hydronic pipes feeding the zones are exposed and although the joists are insulated with fiberglass, enough heat escapes the floor above to moderate the cellar temp.. The radiant is divided into 5 zones. This was a DIY from 20 years ago. A Monitor MZ25, wall hung, condensing boiler has been in place since built. It has been struggling with various issues and last night the igniter stopped functioning. It will not be repaired as there are combustion chamber fractures and today it was removed.

I have a Westinghouse WBRCLP140 that was purchased 2 years ago, but has never been commissioned. I would like to put this boiler in the system. I thought , when I purchased it that the 10:1 turn down ratio would make a good fit. I don't know now. The more I read the less I know.

Calculated heat loss from walls windows and ceiling, including basement is approximately 51Kbtu. This does not include any loss from air exchange. The 5 zones are approx, without account for air infiltration, 7.4Kbtu, 5.4Kbtu, 4.3Kbtu, 10.5Kbtu, 13.5Kbtu. The basement adds 9.4Kbtu.

Each zone is 4, 5 or 6 loops of 1/2" pex on top of plywood sub-floor in 2" gypcrete. Typical loop is 100'-140', IIRC run off of Wirsbo mainfolds with each loop having an adjusting valve. The main manifold off the boiler is regulated by Taco zone valves and zone control.

So my question comes in regarding water distribution. I don't have much of a grasp on this part of the system, but I would like to add to it if that is appropriate (both my grasp and the hardware). There has been no mixing valve or primary/radiant loop or close proximity Ts or buffer tank or any kind of water diversion in the system so the heated water has been fed directly into the distribution manifold that sits next to the boiler. The old boiler had a circulating pump and there was another circulating pump prior to the zone valves. I guess the house has typically been comfortable, but from what I am reading lately, it seems the water distribution isn't designed as it should be.

The previous boiler was not modulating and there were times when short cycling was an issue. Output temp has been run between 117F and 125F over the years. Last year I had been opening a couple zone valves manually because the wax motors failed. This was kind of a good thing as the short cycling was somewhat mitigated, I suppose because it made a larger zone by combining them.

I would like to get this straightened out as best I can, even if the distribution isn't perfect. I can do the installation with some good advice. Once I have it set up as best I can, I'll have someone come in and inspect the gas fittings and get the initial fire up.

Here is the existing distribution with a Taco 007-F5. There is a Grundfos Type UPS 15-42 F I took out of the old boiler available as well.

Thanks again for any interest and help.