You don't have to take the CSV1A out of line to clean or repair. Simply unscrew the red top and pull the gut pack or A-Cart out to clean it. Here is a drawing of the breakdown and a picture of the A-Cart, which is the replacement cartridge if you need one.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LOT of iron 3 years after new well. Want to install my CSV.

- Thread starter Rmgolob

- Start date

Users who are viewing this thread

Total: 2 (members: 0, guests: 2)

Sarg

Enjoy Learning

Mr. Austin ....... In your experience how long before the repair parts are required ?

The immediate symptom would be the CSV doesn't sustain the set pressure ?

The immediate symptom would be the CSV doesn't sustain the set pressure ?

Sponsor

Paid Advertisement

With a lot of sand or sediment maybe 10 years. Clean water 30+ years.

Funny but maddening story. My oldest customer and good friend from Canada sent me this pic yesterday. This is a CSV I built personally in about 1995. It is still working perfectly. However, the owner noticed his pump was running all the time and called my friend for a service call. The owner wanted to "upgrade" to a variable speed pump system. My friend laughed and said the CSV is the "upgrade". The pump is running constantly because there are 50 mobile homes connected to this pump system. The CSV has been keeping the pump running 24/7/365 for all these years, which is WHY he hasn't had ANY problems in all these years.

I don't understand people sometimes. He wants to change something that works so well it hasn't been touched in decades? I see this a lot however. Most pump guys will gladly remove the $100 Cycle Stop Valve and sell them a $4K variable speed system. They make good money for removing the Cycle Stop Valve. Then they also get to make even more money by having to replace the variable speed stuff often, instead of the customer getting 30 years without even a single service call from the old CSV system.

I don't understand people sometimes. He wants to change something that works so well it hasn't been touched in decades? I see this a lot however. Most pump guys will gladly remove the $100 Cycle Stop Valve and sell them a $4K variable speed system. They make good money for removing the Cycle Stop Valve. Then they also get to make even more money by having to replace the variable speed stuff often, instead of the customer getting 30 years without even a single service call from the old CSV system.

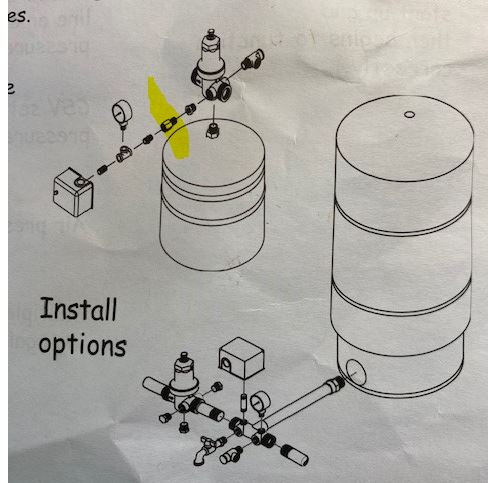

Awwsome!You don't have to take the CSV1A out of line to clean or repair. Simply unscrew the red top and pull the gut pack or A-Cart out to clean it. Here is a drawing of the breakdown and a picture of the A-Cart, which is the replacement cartridge if you need one.

View attachment 71715

View attachment 71716

Got it!

Follow up question(s):

1. I cant imagine there is a difference with the switch or the gage being first (closest to the CSV) - Correct?

2. What is the highlighted gizmo and what does it do? I assume it's direction IS important?

1. I cant imagine there is a difference with the switch or the gage being first (closest to the CSV) - Correct?

2. What is the highlighted gizmo and what does it do? I assume it's direction IS important?

Just a little snubber to keep the pressure gauge from flickering. Both switch and gauge go after the snubber.

Sarg

Enjoy Learning

And every day we learn something else.

Follow up question numbers ?? and ??

Do I need to maintain 1" outlet from the CSV for a particular length?

Assuming not, can I put a 1 x 3/4 bushing directly into the outlet?

Can I then run a 3/4 Elbow immediately into the bushing?

No turbulence or friction issues?

Do I need to maintain 1" outlet from the CSV for a particular length?

Assuming not, can I put a 1 x 3/4 bushing directly into the outlet?

Can I then run a 3/4 Elbow immediately into the bushing?

No turbulence or friction issues?

Taylorjm

Active Member

Funny but maddening story. My oldest customer and good friend from Canada sent me this pic yesterday. This is a CSV I built personally in about 1995. It is still working perfectly. However, the owner noticed his pump was running all the time and called my friend for a service call. The owner wanted to "upgrade" to a variable speed pump system. My friend laughed and said the CSV is the "upgrade". The pump is running constantly because there are 50 mobile homes connected to this pump system. The CSV has been keeping the pump running 24/7/365 for all these years, which is WHY he hasn't had ANY problems in all these years.

I don't understand people sometimes. He wants to change something that works so well it hasn't been touched in decades? I see this a lot however. Most pump guys will gladly remove the $100 Cycle Stop Valve and sell them a $4K variable speed system. They make good money for removing the Cycle Stop Valve. Then they also get to make even more money by having to replace the variable speed stuff often, instead of the customer getting 30 years without even a single service call from the old CSV system.

View attachment 71718

I just don't understand how taking a pump and restricting the flow is a good thing. If the pump is putting out 20gpm at 50psi, and your restricting it to say 5gpm when someone is taking a shower, where is the remaining 15gpm going? The pressure on the line prior to the csv is going to increase dramatically. So higher pressure, lower volume, and the pump is running the same rpm's?

Sarg

Enjoy Learning

Follow up question numbers ?? and ??

Do I need to maintain 1" outlet from the CSV for a particular length?

Assuming not, can I put a 1 x 3/4 bushing directly into the outlet?

Can I then run a 3/4 Elbow immediately into the bushing?

No turbulence or friction issues?

My set up below before installation and the cyclestopvalve site has hundreds of photos of successful applications.

https://cyclestopvalves.com/pages/reviews

Attachments

Yes, yes, yes, and yes. And the current goes down, surprisingly enough. Counter-intuitive.I just don't understand how taking a pump and restricting the flow is a good thing. If the pump is putting out 20gpm at 50psi, and your restricting it to say 5gpm when someone is taking a shower, where is the remaining 15gpm going? The pressure on the line prior to the csv is going to increase dramatically. So higher pressure, lower volume, and the pump is running the same rpm's?

You want to make sure the pipe can take the pressure. The maximum pressure at zero gpm is in the pump specs. The pressure the pipe sees is something less than that.

I just don't understand how taking a pump and restricting the flow is a good thing. If the pump is putting out 20gpm at 50psi, and your restricting it to say 5gpm when someone is taking a shower, where is the remaining 15gpm going? The pressure on the line prior to the csv is going to increase dramatically. So higher pressure, lower volume, and the pump is running the same rpm's?

Yeah I know, pumps are counter intuitive as was said. Back pressure is good for a pump. Too little back pressure is bad. Making a pump run 24/7/365 is good for a pump. Reducing or eliminating on/off cycles is good for the pump. Without a CSV running "just a little water so I don't hurt the pump", causes cycling and is the worst thing you can do to a pump.

Pump manufacturers will just let you keep thinking like that and will sell you a $4K variable speed system that won't last very long instead of a $200 CSV system that will do a better job and make the pump last 30 years. True innovation is stifled by planned obsolescence and manufacturers greed. The old adage "buyer beware" has never been more true than when talking about pumps, as pump manufacturers will sell you what they make the most profit on, not what is best for you.

Taylorjm

Active Member

Yeah I know, pumps are counter intuitive as was said. Back pressure is good for a pump. Too little back pressure is bad. Making a pump run 24/7/365 is good for a pump. Reducing or eliminating on/off cycles is good for the pump. Without a CSV running "just a little water so I don't hurt the pump", causes cycling and is the worst thing you can do to a pump.

Pump manufacturers will just let you keep thinking like that and will sell you a $4K variable speed system that won't last very long instead of a $200 CSV system that will do a better job and make the pump last 30 years. True innovation is stifled by planned obsolescence and manufacturers greed. The old adage "buyer beware" has never been more true than when talking about pumps, as pump manufacturers will sell you what they make the most profit on, not what is best for you.

So if your talking about the typical 1/2hp submersible pump what kind of pressure will you see between the pump and the csv when the flow is restricted?

LLigetfa

DIYer, not in the trades

There really is not a typical 1/2HP pump. They vary by the number of stages and by the static water level. The more stages for lifting from greater depth, the higher the deadhead pressure but the lower the GPM. The pump curves for the actual pump model will show the pressure as @Reach4 mentioned.So if your talking about the typical 1/2hp submersible pump what kind of pressure will you see between the pump and the csv when the flow is restricted?

So if your talking about the typical 1/2hp submersible pump what kind of pressure will you see between the pump and the csv when the flow is restricted?

A 10 GPM, 1/2HP can only build about 231' of head which is the same as 100 PSI. 1 PSI of that will be lost for every 2.31' to the static water level. You need at least 70 PSI to work with a 40/60 pressure switch. This means with a 10 GPM, 1/2HP pump the water level in the well cannot be deeper than about 76' deep, or there will not be 70 PSI at the surface.

Now if you have a 3HP, 10 GPM pump it can build 930' or head, which is the same as 402 PSI. But a 10 GPM, 3HP is made for a deep well, so if the water level is at 700' there will still be less than 100 PSI back pressure at the surface.

Unless the pump is WAY oversized there should always be less than 150 PSI back pressure from a CSV. However, as long as the pipe can handle the pressure, even 300 PSI back pressure is not bad but actually good for a 3HP, 10 GPM pump. In cases where the pumping level is 700+' deep but the static is at 10', we use two CSV1A valves to stair step the pressure down from 300 to the 50 PSI constant that is needed with a 40/60 switch.

Myers 1.5 HP, 2 wire, 20 GPM.A 10 GPM, 1/2HP can only build about 231' of head which is the same as 100 PSI. 1 PSI of that will be lost for every 2.31' to the static water level. You need at least 70 PSI to work with a 40/60 pressure switch. This means with a 10 GPM, 1/2HP pump the water level in the well cannot be deeper than about 76' deep, or there will not be 70 PSI at the surface.

Now if you have a 3HP, 10 GPM pump it can build 930' or head, which is the same as 402 PSI. But a 10 GPM, 3HP is made for a deep well, so if the water level is at 700' there will still be less than 100 PSI back pressure at the surface.

Unless the pump is WAY oversized there should always be less than 150 PSI back pressure from a CSV. However, as long as the pipe can handle the pressure, even 300 PSI back pressure is not bad but actually good for a 3HP, 10 GPM pump. In cases where the pumping level is 700+' deep but the static is at 10', we use two CSV1A valves to stair step the pressure down from 300 to the 50 PSI constant that is needed with a 40/60 switch.

Replaced a Grundfos 3/4 HP, 10 GPM.

Pump hanging from 60 ft PVC and water level is about 10-12 feet over that.

I assume I am good?

Yep! 1.5HP, 20 GPM pump builds a max of 138 PSI. 50' to water means you will see 116 PSI back pressure before the CSV, which is good.

Taylorjm

Active Member

Yep! 1.5HP, 20 GPM pump builds a max of 138 PSI. 50' to water means you will see 116 PSI back pressure before the CSV, which is good.

Here's one of my concerns. For instance, I have a sprinkler pump that pulls water from the lake to my underground sprinkler system. There are multiple zone valves that open using the water from the pump. There was a valve failure that caused one zone to not open, so only one smaller zone of sprinklers was open. Because of less flow, the water inside the pump wasn't enough to cool the pump and the impeller melted because of the heat build up. So if your well pump is capable of 20gpm, and is constantly running with only 1 gpm flow, what's to stop the pump from being damaged due to lower flow?

Similar threads

- Replies

- 2

- Views

- 948

- Replies

- 7

- Views

- 2K

- Replies

- 5

- Views

- 755

- Replies

- 2

- Views

- 718