Okay, I've given it some thought and here are the best options I've come up with. I'm going to assume that you want to leave the 3" line located in the soffit as it currently is. And that upstream of the bend shown in the 2nd photo in the thread (which should be a LT90, can't tell from the photo) are the two lav drains, which are vented through the roof (to be confirmed).

First, an important building code note: the area above that soffit is not properly fireblocked. The point of fireblocking here is so that if fire gets into one of the stud bays, it does not immediately rise up the bay into the soffit and spread to all the floor joist bays. So each stud bay is supposed to be closed off so it doesn't communicate with the soffit or any of the joist bays. For details, see:

https://up.codes/viewer/kansas/irc-2018/chapter/3/building-planning#R302.11

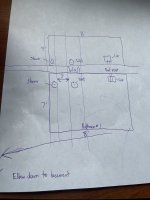

Second, how to run the two WC drains so they are properly vented? The 3" horizontal line in the soffit can vent each WC, since the IPC (in use in Kansas) allows up to two bathroom groups on a single horizontal wet vent. And since WCs have an integral trap, there's no regulation of the elevation at which the WC fixture drain joins the 3" horizontal line.

But the two WCs do have to be kept separate. So if running the outlet of the far WC's closet bend parallel to the joists would cause it to run under the closer WC's closet flange, the far WC drain should offset to one side or the other within the joist bay. E.g. by rotating the closet bend so its ouput is at a 22.5 or 45 degree angle to the joists, and then using a 22.5 or 45 degree elbow to turn to parallel to the joists (and to line up as required for later connection to the 3" horizontal line in the soffit, see below).

Then the only remaining question is how to connect each WC fixture drain to the 3" horizontal line. It needs to be with a wye (or combo), not a san-tee on its back. And separately, so you'll need (2) 3" wyes. If space is tight, you may want the upstream wye to be street so it can connect directly to the downstream wye.

Now there is some difference of opinion about the allowable orientation of that wye's branch inlet for horizontal wet venting. Some say that the wye can have the inlet on top. Then on the near WC (directly over the 3" horizontal soffit line) you can just use a 45 below the flange to hit an upright wye (or just use an upright combo), and on the far WC drain you'd just need to use a quarter bend on the horizontal line, with the outlet turned 45 degrees off plumb and pointed at the wye.

But there is also a school of thought that the wye needs to "horizontal" for horizontal wet venting. In that case I would think it would be OK to roll the wye 45 degrees off vertical, as then its inlet would be considered horizontal. With a wye in that orientation, a 60 degree bend on the branch inlet will either get you to vertical, or horizontal perpendicular to the joists (not useful here); and a 45 would get you horizontal parallel to the barrel of the wye (always possible, not dependent on how much the wye is rolled). So the near WC drain could jog away from the wall with two 45s, then the vertical would hit a 60 to hit the wye rolled up 45 degrees. And the far WC drain would run slightly beyond the 3" horizontal soffit drain, then hit a quarter bend rolled 45 degrees, then a 45 degree to go horizontal, parallel to the 3" horizontal soffit line, with a 45 and wye to join the 3" horizontal soffit line.

Getting all of the above to fit in one joist bay may be a bit of a challenge without hitting the joists. The challenge would probably be minimized by having the horizontal line coming from the far WC cross over the top plate as low as possible (maybe minimum 1/4" clearance). That way the first fitting on that line will more quickly enter the unconstrained soffit area under the joists. But depending on the height required for some of the above fitting configurations, you may need to have the far WC fixture drain higher up in the joist bay, assuming that it will fit without hitting the joists.

More to follow.

Cheers, Wayne